Prioritising Material Stability and Long-Term Performance

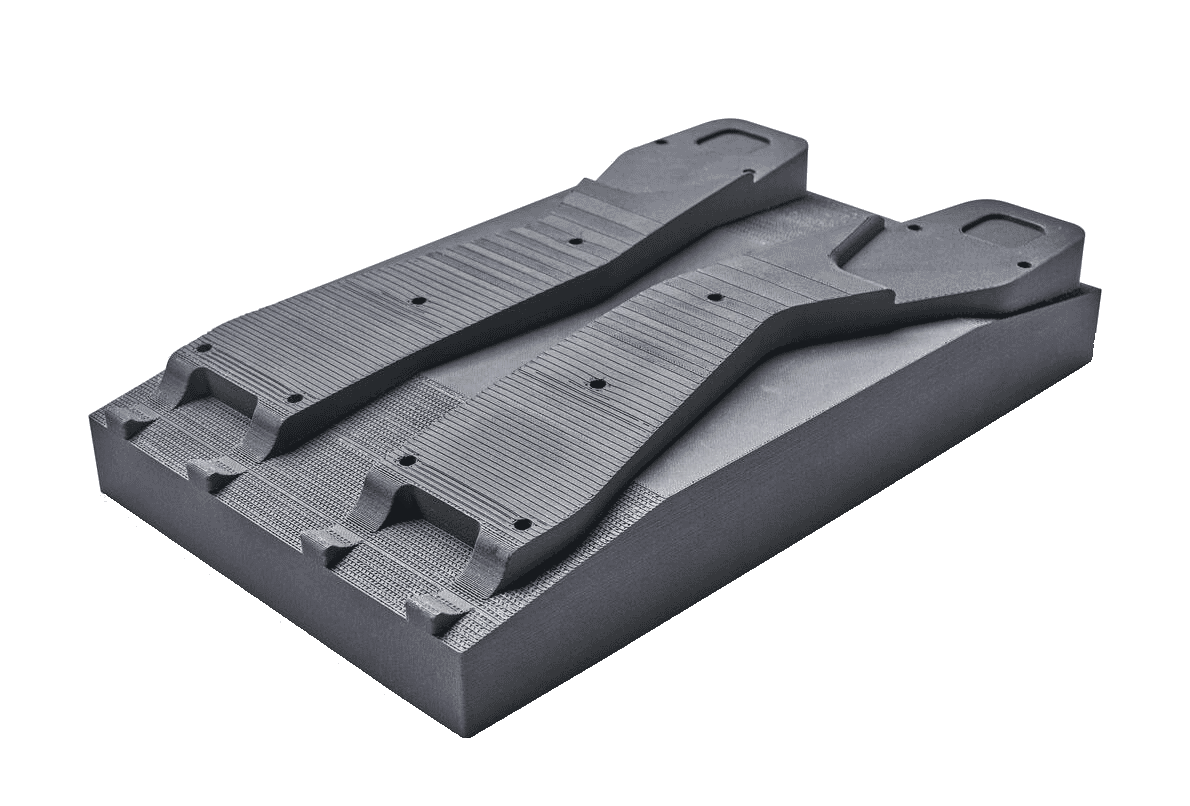

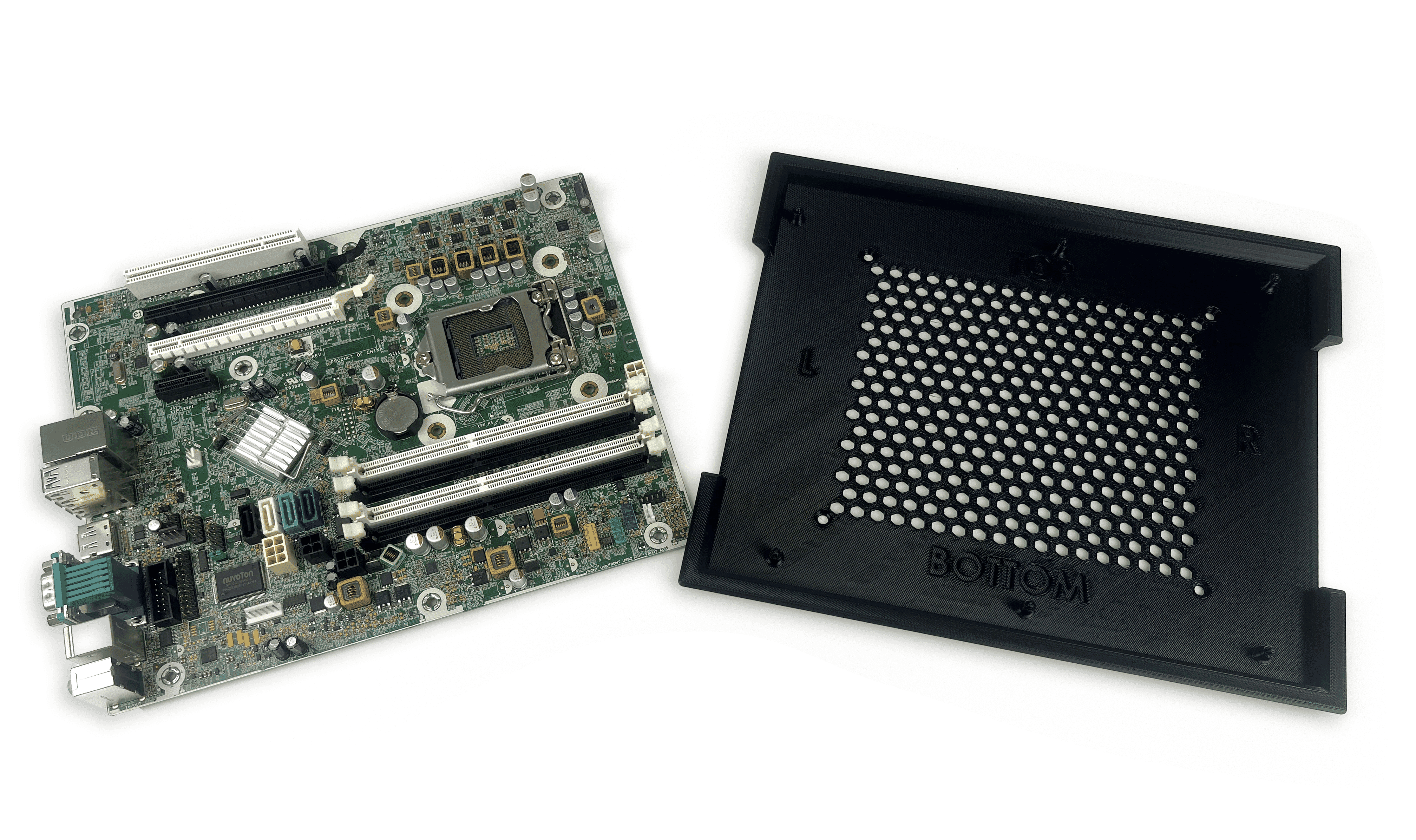

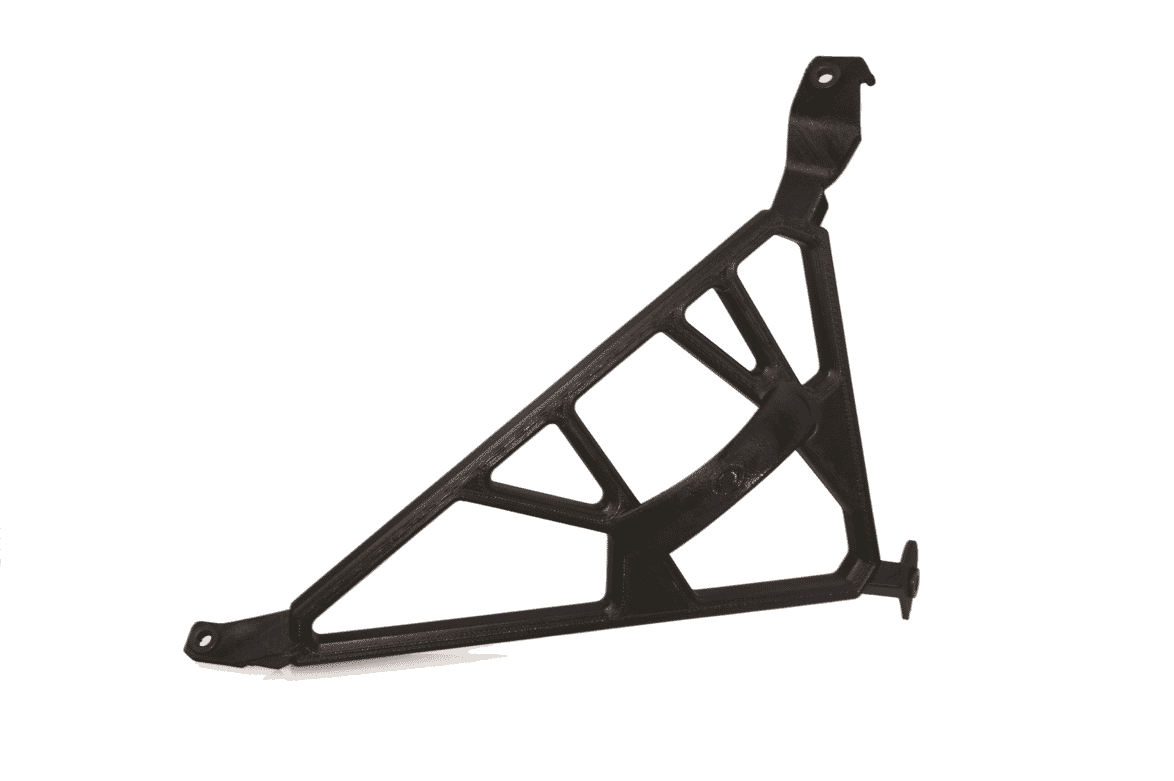

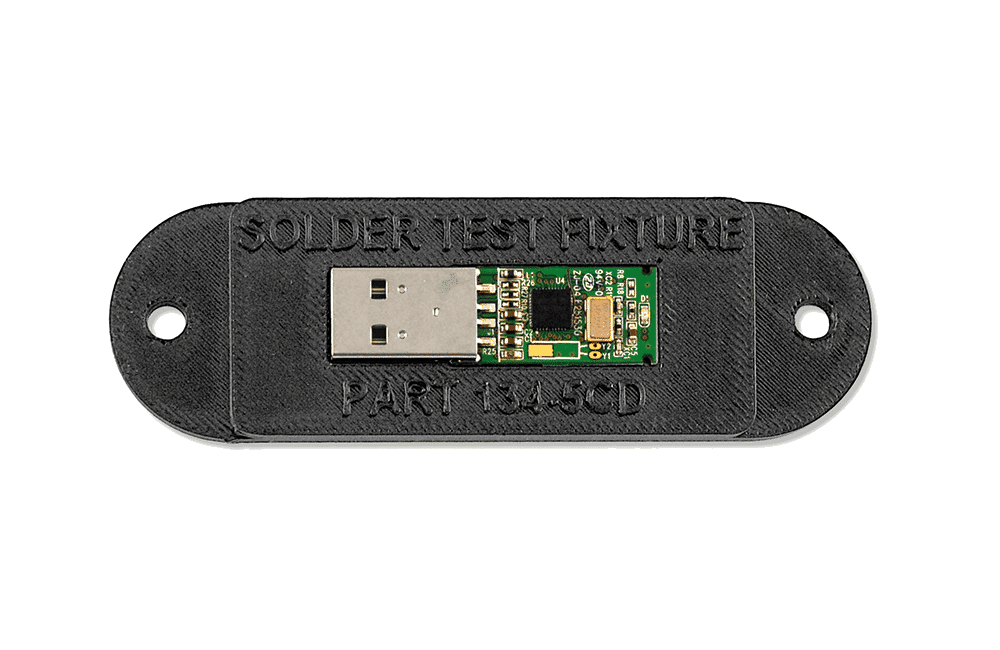

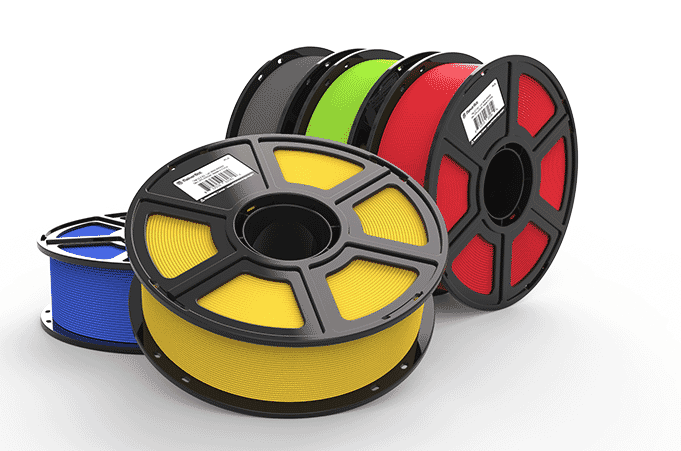

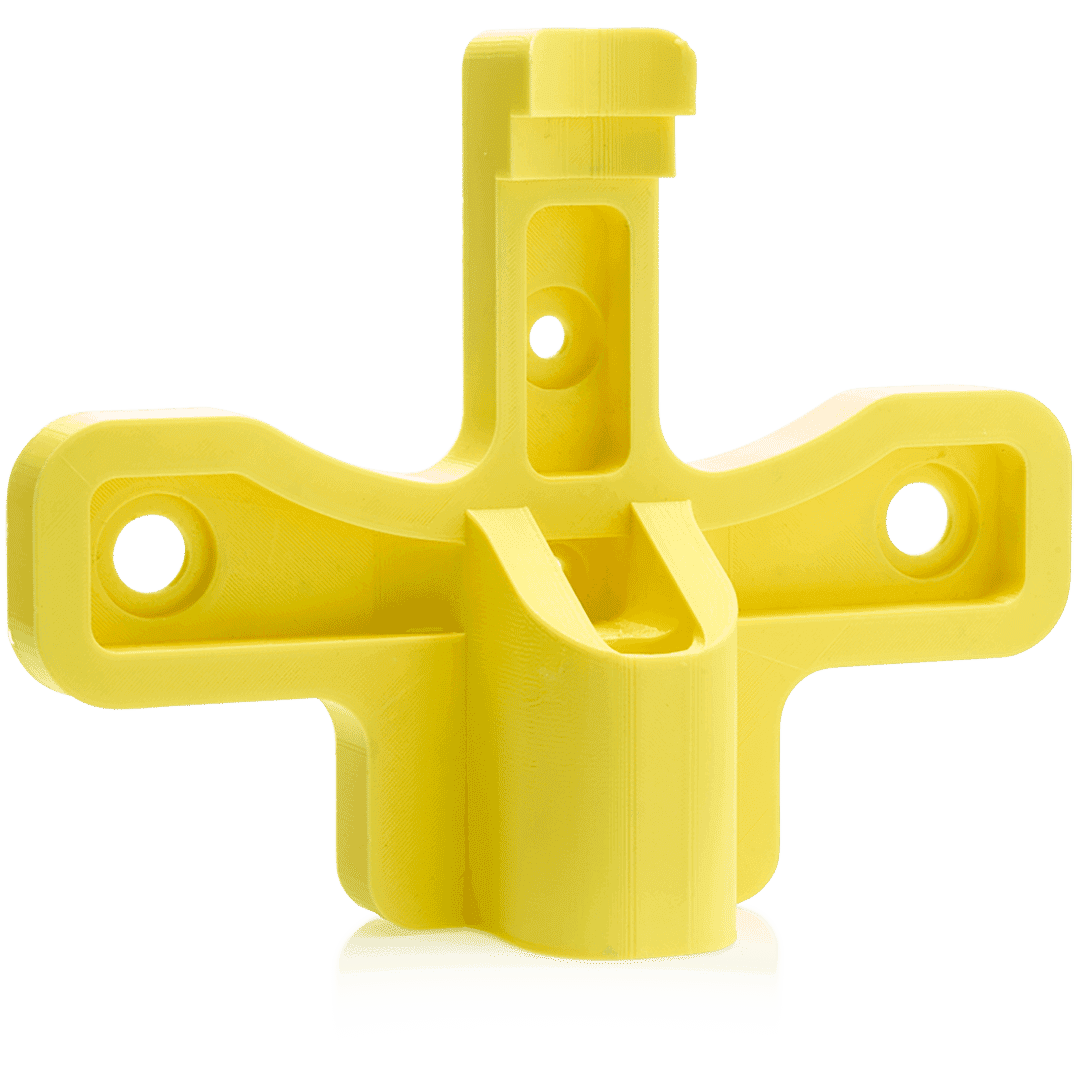

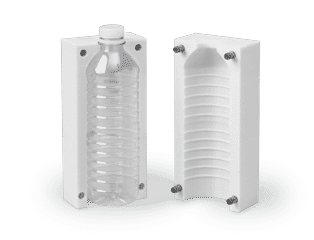

Thermoplastics are derived from the same raw materials as those used in injection molding. These versatile materials are ideal for a range of applications, from initial concept modeling to product development and full-scale manufacturing. Like molded parts, thermoplastics come in a wide range of options, each with its own unique characteristics tailored to specific application requirements.

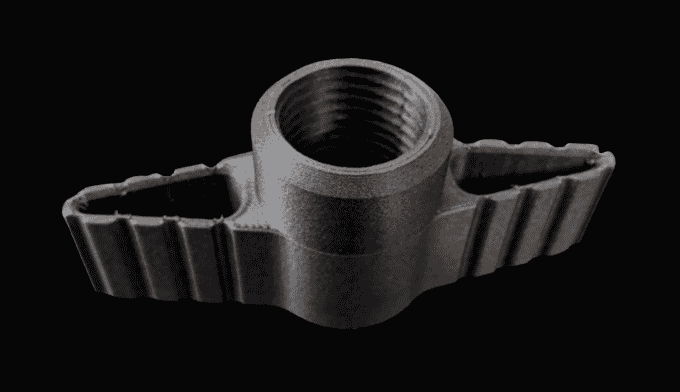

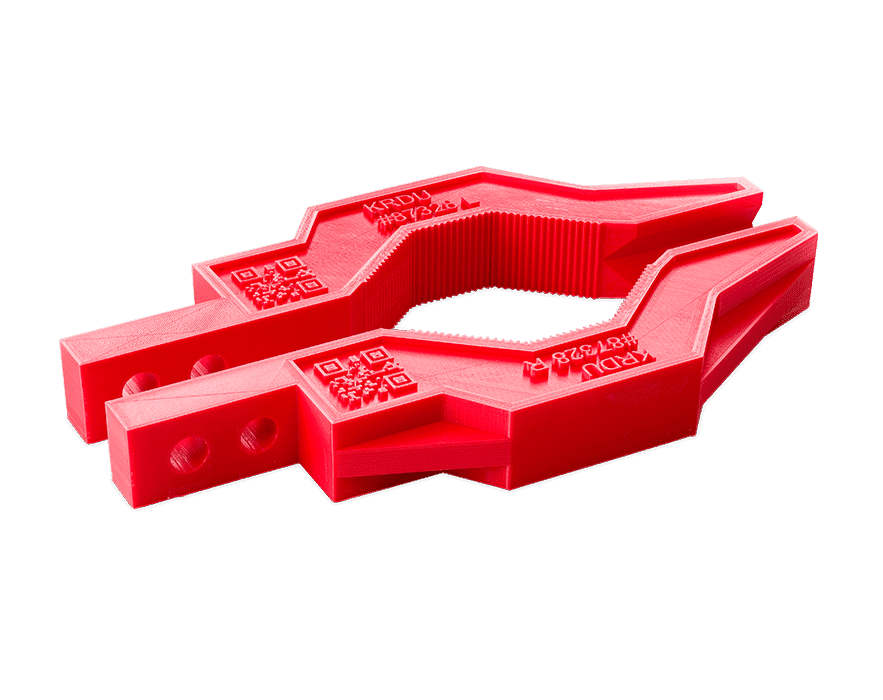

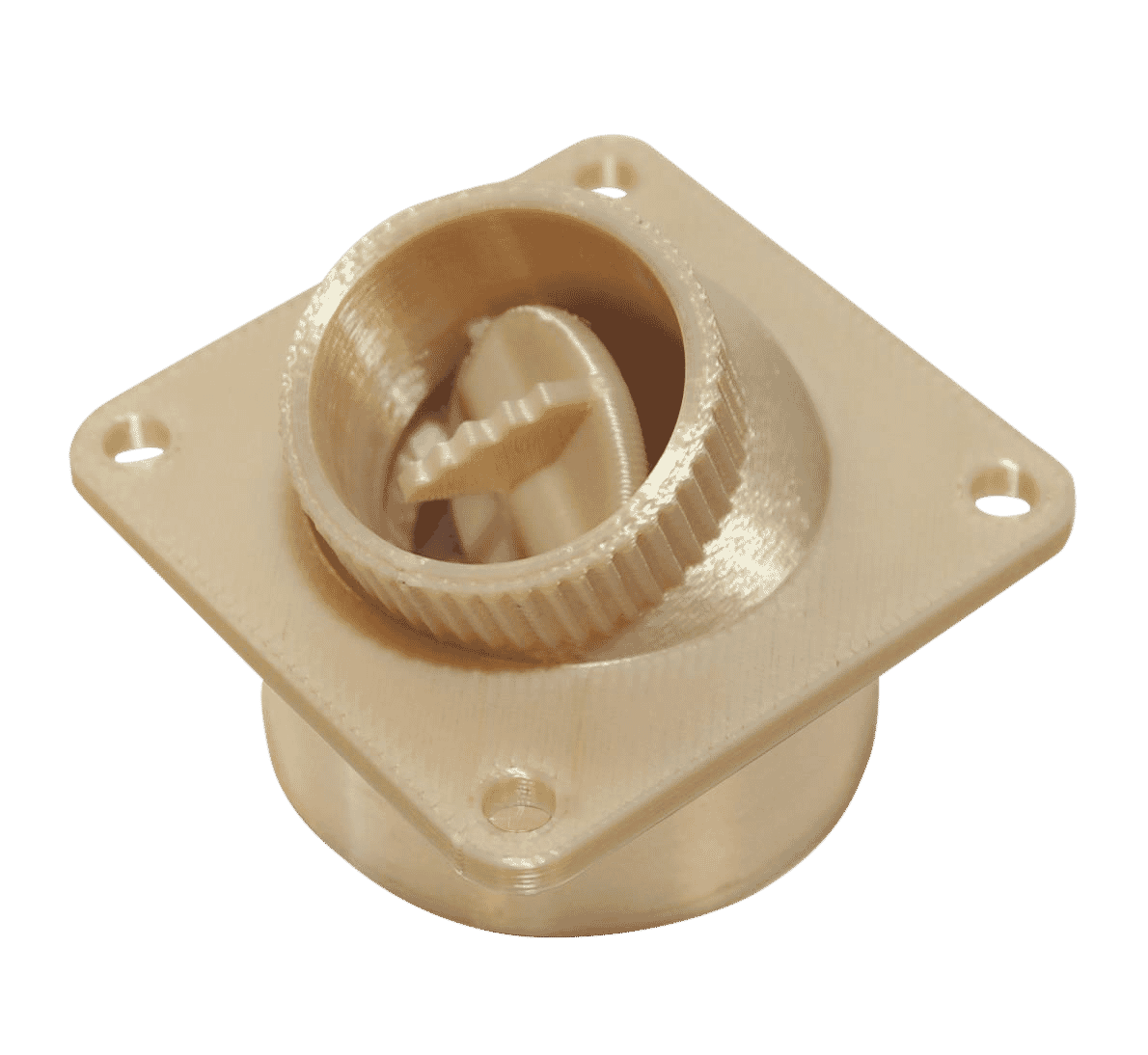

One of the primary reasons for the widespread use of 3D printing with thermoplastics is the ability to create parts using the most commonly used materials, including ABS, polycarbonate, and a variety of blends. In addition, there are engineered thermoplastics designed for aerospace, medical, automotive, electronic, and other specialty applications. When producing finished goods using 3D printing, the use of thermoplastics is particularly critical, and may be the only option for many applications.

By choosing to 3D print with thermoplastics, engineers have access to a broad range of material options that enable the production of high-quality parts with consistent, reliable results.

View the range