PolyJet 3D Printers

Powerful 3D printing technology that produces smooth & accurate parts.

What is PolyJet printing?

In the upcoming AM sector, PolyJet’s USP was its revolutionary ability to simultaneously print parts made from more than one material. As such, almost overnight, ambitious designers could harness all the advantages of multiple photopolymers in a single build – resulting in complex, multi-coloured, multi-textural parts that could thrive in a thousand different scenarios.

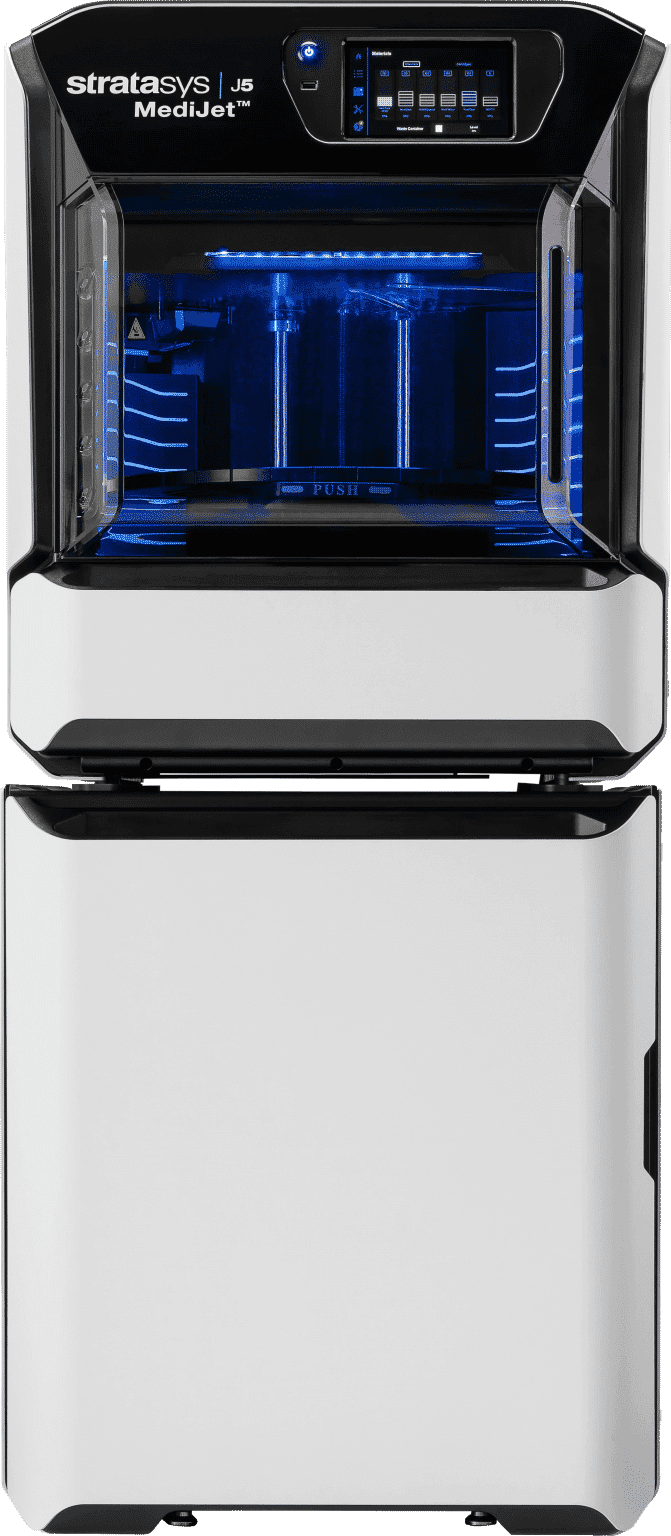

A quarter-century later, choose a modern Stratasys PolyJet 3D printer and you’ll enjoy all the benefits that have become calling cards of this powerful technology. PolyJet-printed parts are known for their smooth and exceptionally precise finish, while this AM technology is also capable of the intricate geometries and details that explain why it is used across the gamut of manufacturing from rapid prototyping and tooling to full production.

PolyJet 3D Printing Benefits

-

Smooth & accuratePolyJet technology enables ambitious design possibilities, ensuring smooth and precise finishes, even when working with the most complex geometries

-

Material choicesNo other AM technology offers a wider range of 3D print materials, with a huge selection of compatible photopolymers available direct from Tri-Tech 3D

-

Unbeatable efficiencyBoost your operation’s output and efficiency by combining multiple materials, different colours and varying textures in a single print

-

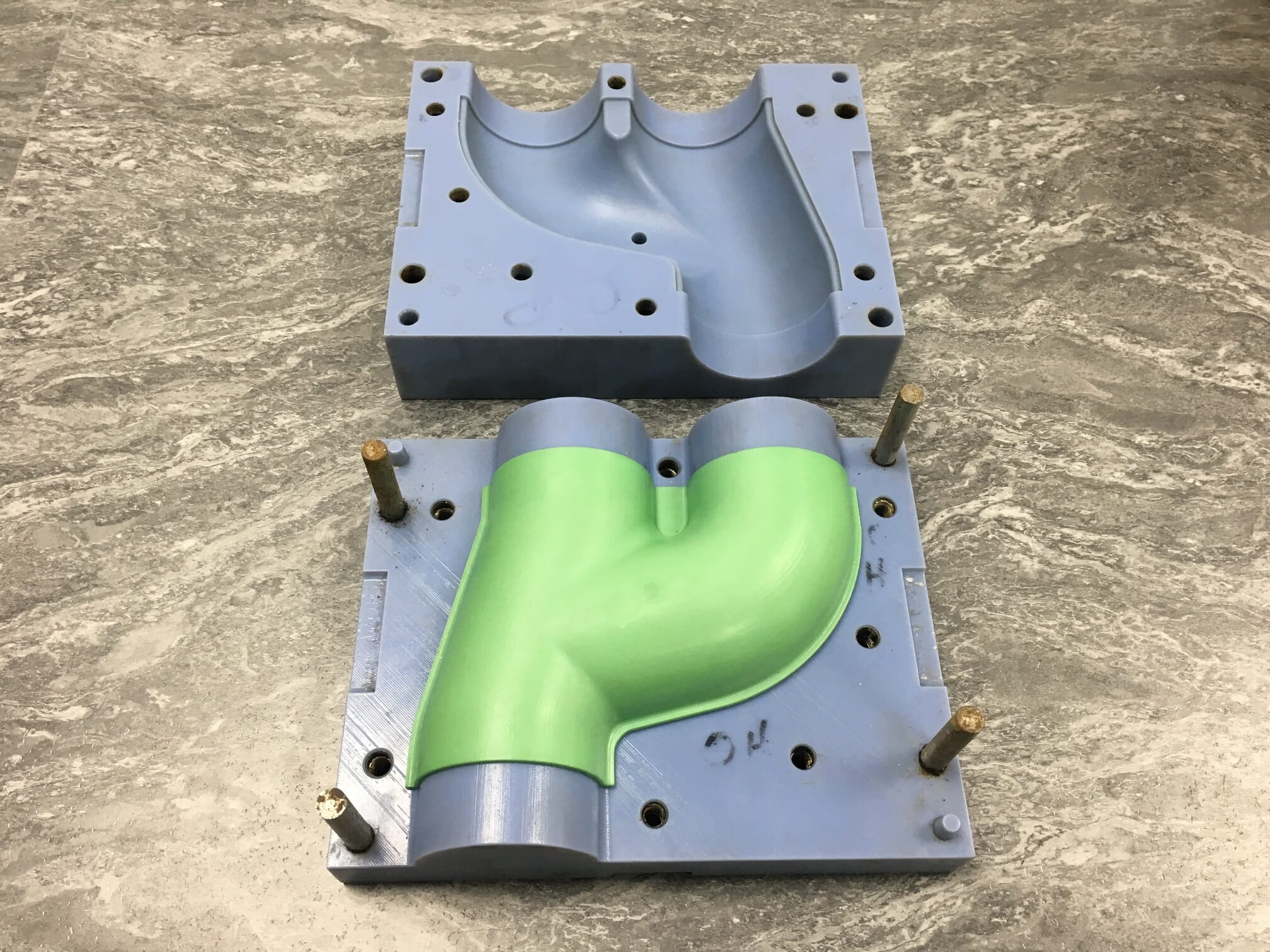

Suitable for all applicationsPolyJet adapts to the project at hand, creating high-quality prototypes, final products and precise manufacturing tools including moulds, jigs and fixtures

-

Easier workflowStay on track and in control, with PolyJet technology allowing a smoother concept-to-production workflow using Stratasys’s own GrabCAD software

-

Simpler operationIntuitive operation lets Stratasys PolyJet 3D printers integrate seamlessly with your business, right down to convenient pre-filled material cartridges

CASE STUDY

Quadpack enhances packaging design with PolyJet

Quadpack enhances packaging design and production with the Stratasys J Series 3D printer. In a step aimed at increasing innovation, Quadpack purchased a Stratasys J750 from Tri-Tech 3D. The 3D printer is now at the heart of the Design and Advanced Technologies department.

-

How does Stratasys PolyJet work?

PolyJet 3D printers employ photopolymers, UV light and inkjet heads to create some of the highest-quality parts possible using additive manufacturing. The fundamental principle sees droplets of photopolymer jetted onto the printer’s build platform, then cured by a UV lamp, so bonding the resin and forming the layers of the component. However, the Stratasys range of PolyJet 3D printers goes further, with flagship models like the J850 Prime offering additional print modes, an uprated material capacity (up to 7 base resins), access to over 500,000 colours and much more.

-

How long does PolyJet printing take?

PolyJet is an industrial 3D printing process that can produce multi-material prototypes and complex parts in as little as one day. The time it takes to print an object depends on the material and the size and detail of the model, but it can range from 30 minutes to several days. For example, an iPhone-sized device can take 4–6 hours to print, depending on the material. Opaque materials are printed in 28-micron layers, while clear materials are printed in 16-micron layers.

-

What are PolyJet printers used for?

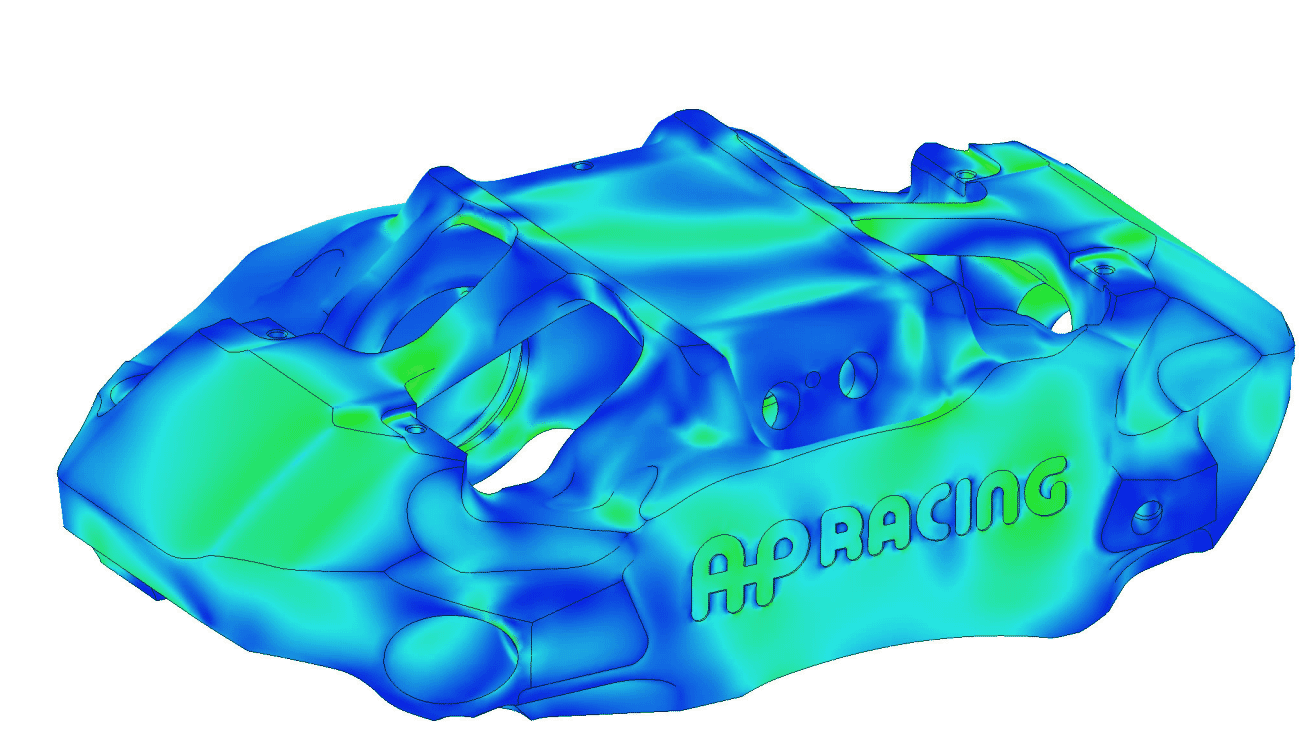

As you’ll see from our case studies, PolyJet’s enviable accuracy and ability to create high-precision parts has made this technology a mainstay in forward-thinking sectors like architecture, healthcare, defence, aerodynamics, automotive and entertainment. You’ll find PolyJet employed for everything from the internal mechanics of Formula One race cars to groundbreaking multi-texture packaging in the cosmetics industry. But perhaps this technology’s most impressive application is the creation of patient-specific medical products from dentures to simulated human tissue.

-

What makes PolyJet 3D printing unique?

PolyJet shares some similarities with other material-jetting technologies, but just one of its unique features is the ability to print in full colour. It’s no wonder that PolyJet has become the go-to for companies whose products need form as well as function, with this technology fast becoming the mainstay for full-colour prototypes that look stunning from the moment they leave the build platform. But that is not to suggest that PolyJet can’t produce heavy-duty componentry, with this technology also a trusted choice for tough industrial parts that will endure extreme stress.

-

What is the difference between PolyJet and FDM printers?

At a glance, there are some similarities between the PolyJet 3D printers and Fused Deposition Modelling (FDM) models offered by Tri-Tech 3D. Both of these popular AM disciplines print parts layer-by-layer, but the critical difference is the process, with FDM printers heating a thermoplastic filament, while PolyJet printers jet liquid polymers onto the printer bed. Each technology has its merits and Tri-Tech 3D’s expert team is on hand to discuss which will best suit your needs.

-

What is the surface finish of a PolyJet printer?

PolyJet printers can print parts with a matte or glossy surface finish. The surface finish depends on the orientation of the model, with upward facing areas having a glossy finish and downward facing areas having a matte finish. The matte finish is due to the support material that is placed on downward facing surfaces to support the parts while printing.

-

How accurate is the PolyJet 3D printer?

Stratasys PolyJet 3D printers are amongst the most precise in the AM sector, offering microscopic layer resolution and accuracy of up to 0.014 mm, and so allowing designers to work with intricate geometries and ultra-thin walls that simply wouldn’t be possible with other technologies. Of course, the accuracy will depend on which specific model you choose – from a desktop Polyjet 3D printer like the J35 Pro to the J3 DentaJet designed for dental labs – and our team will be happy to advise you.

-

What is the tolerance for polyjet 3D printing?

Tolerance. Polyjet is one of the most accurate 3D printing processes. This technology deposits layers with a thickness of 0.004 mm, far thinner than a sheet of paper. It produces tolerances of up to ±0.1 mm for the initial dozens of mm and ±0.05 for the ensuing mm.

-

How fast is PolyJet 3D printing?

That depends on the complexity of the print, with multiple materials and/or colours all adding to the build duration. As a general rule of thumb, the highest levels of accuracy at which PolyJet excels are best achieved by using slower print speeds. But you’ll be surprised how fast the process can be when you choose a Stratasys PolyJet 3D printer, with the company’s GrabCAD software letting you print direct (no need to convert or fix STL files), and models like the J826 Prime boasting an output about 200% faster than a traditional unit – potentially cutting weeks off the design cycle.

Most popular PolyJet 3D Printers

What are common applications for PolyJet printers?

New to 3D

Printing or looking

for some support?

- Call: 01782 814551

- Email: info@tritech3d.co.uk