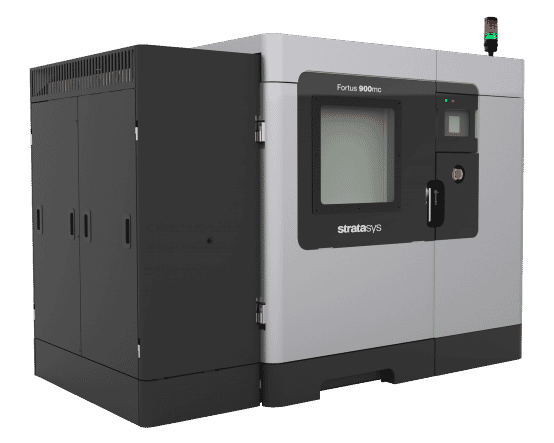

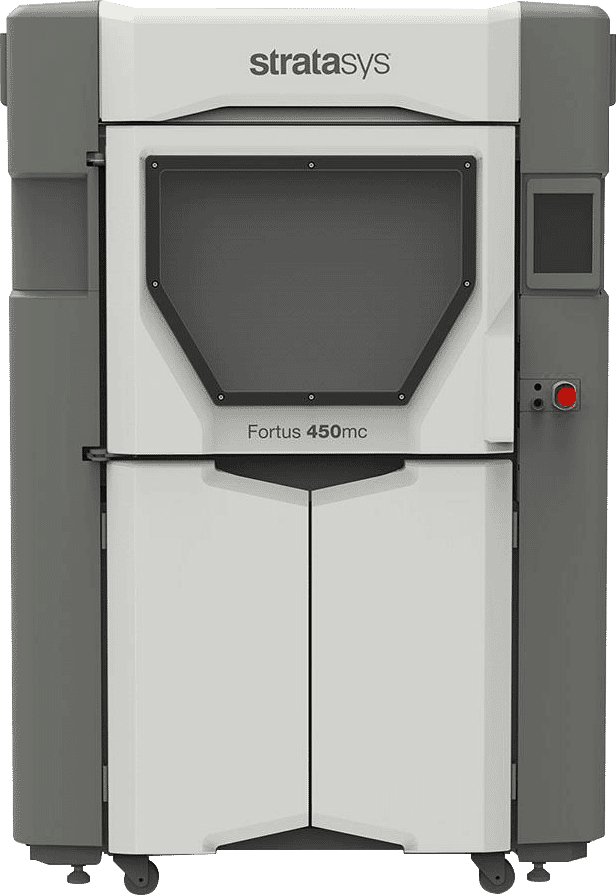

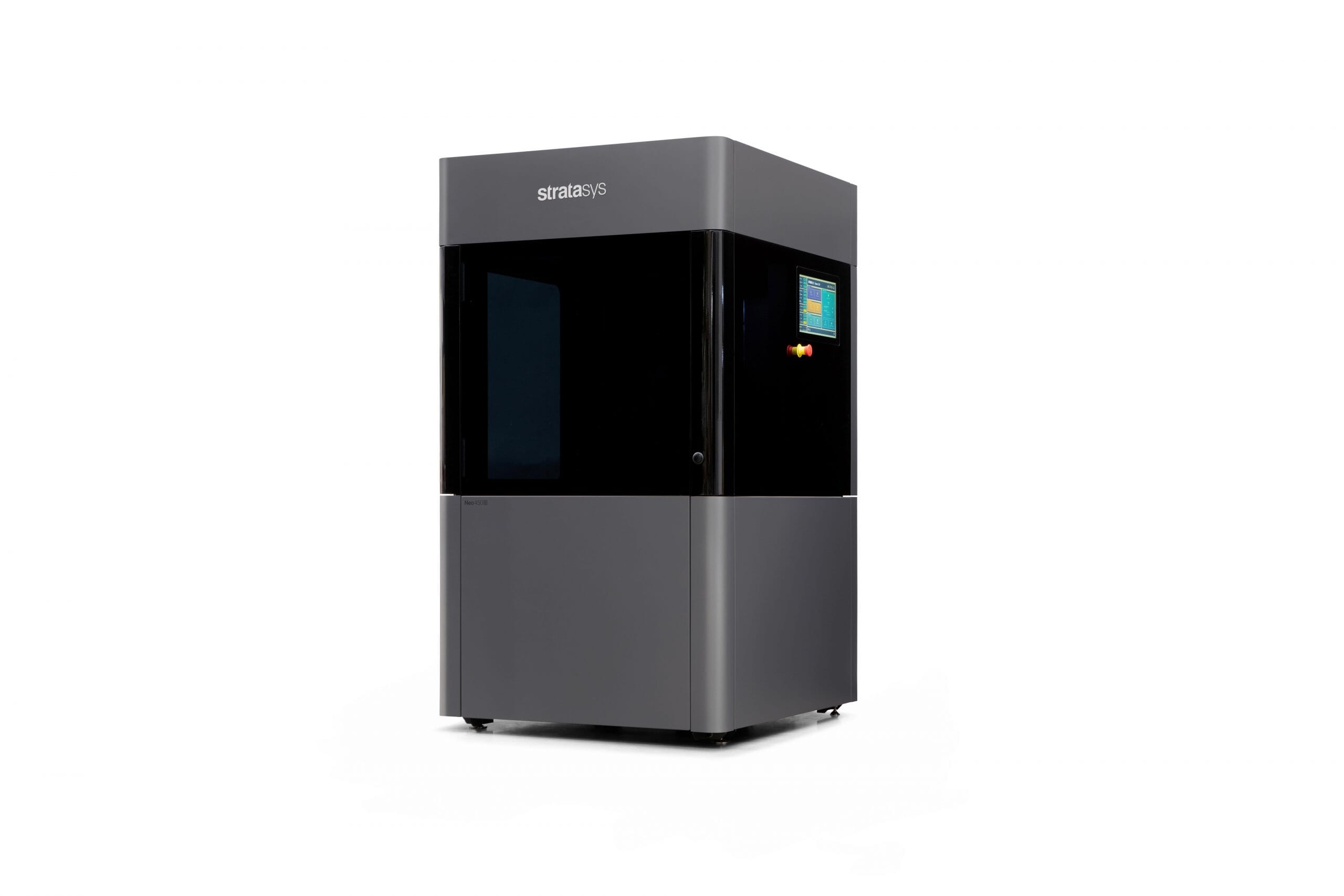

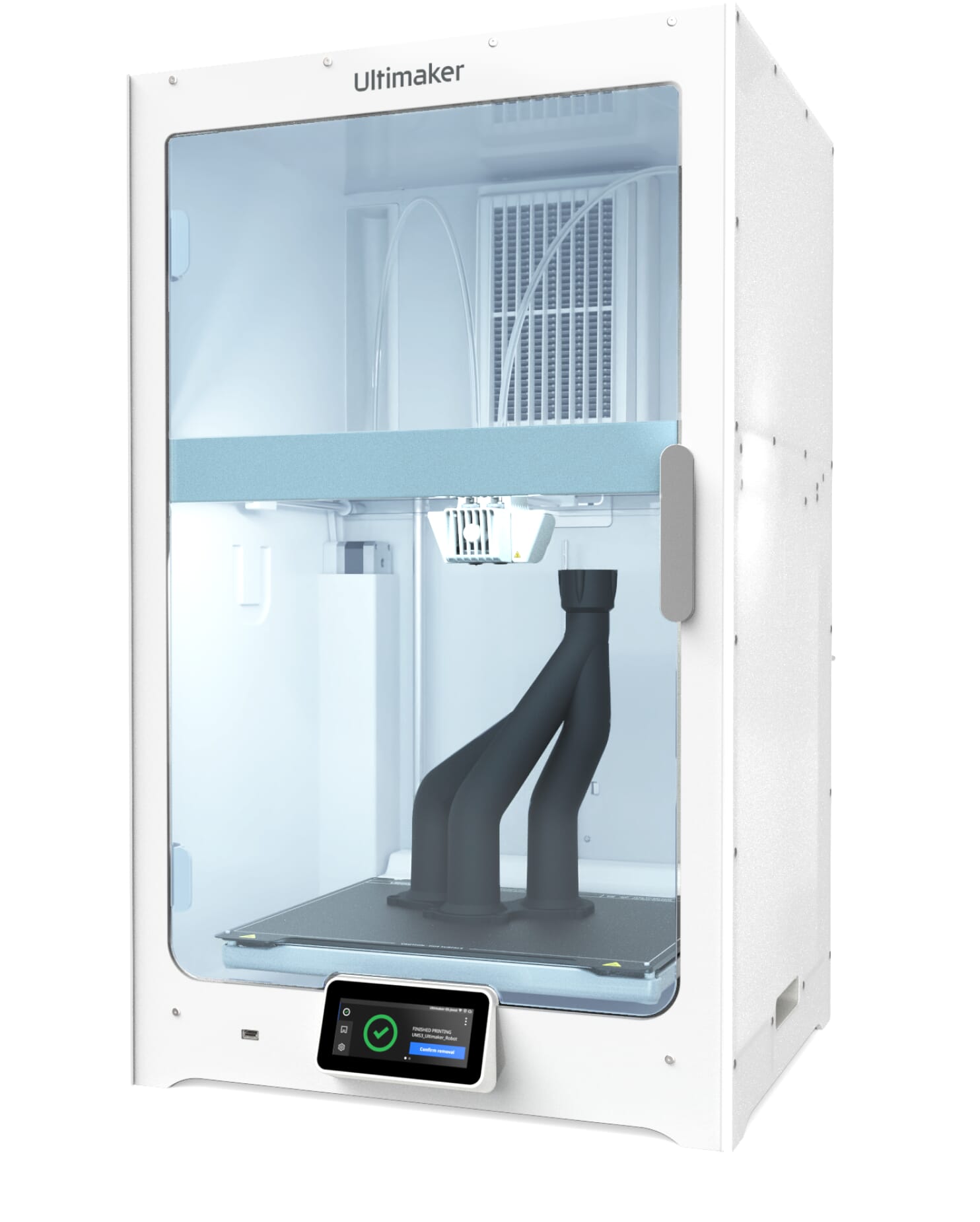

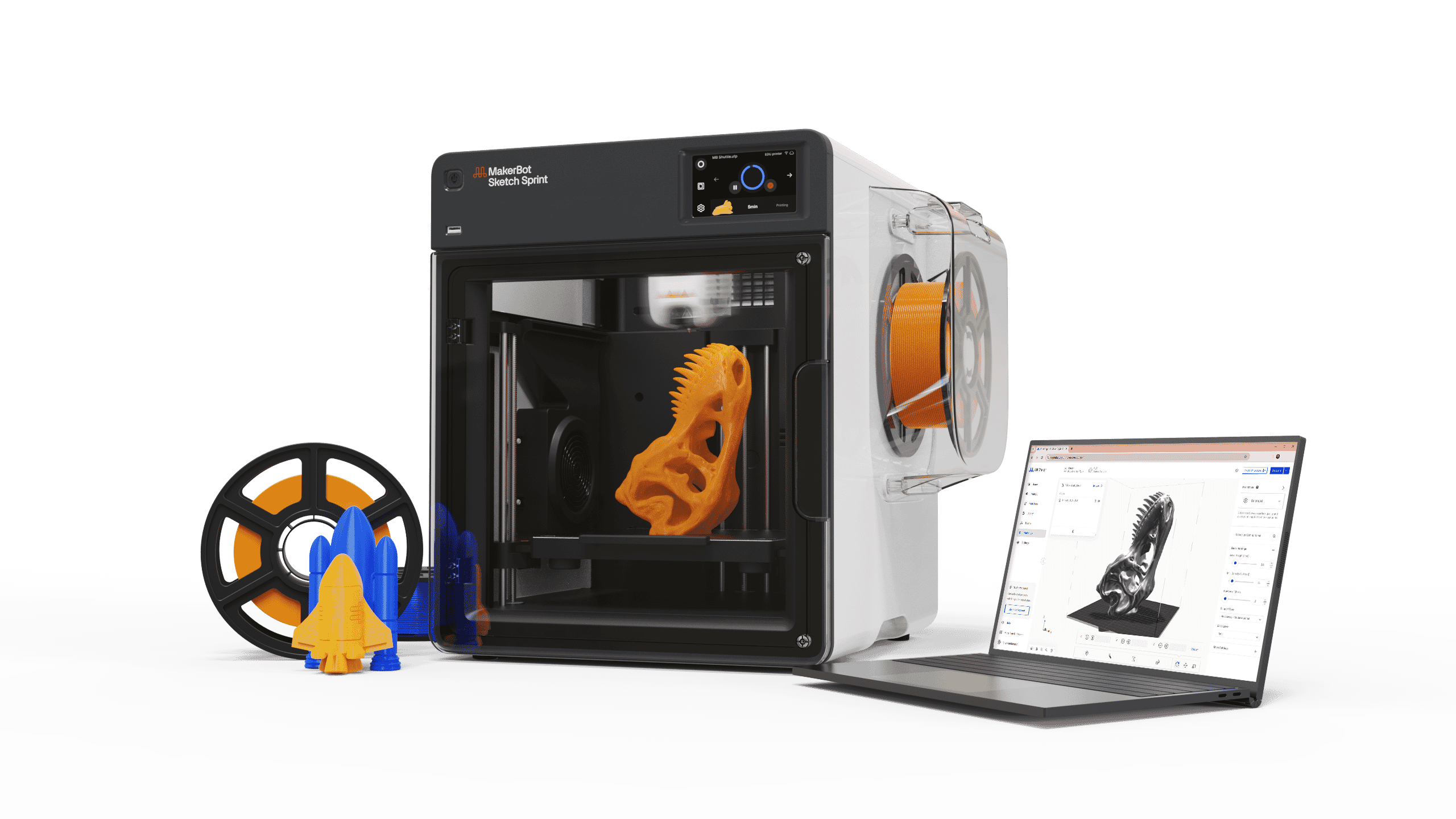

Printers best suited for the application of production parts

Stratasys 3D Printers build the most durable, stable, repeatable parts in the industry. With accuracy that rivals injection molding and an array of real thermoplastic materials, manufacturers can now 3D print low-volume, customized production runs.

3D printed production parts removes the constraints imposed by traditional manufacturing processes, such as injection molding or die casting.

3D Printing production parts benefits

- In the early phases of product release, you can make parts for pilot production runs.

- Use 3D printed parts for replacement applications.

- 3D printed parts can be created while waiting for ramping of tooling and manufacturing equipment and processes.