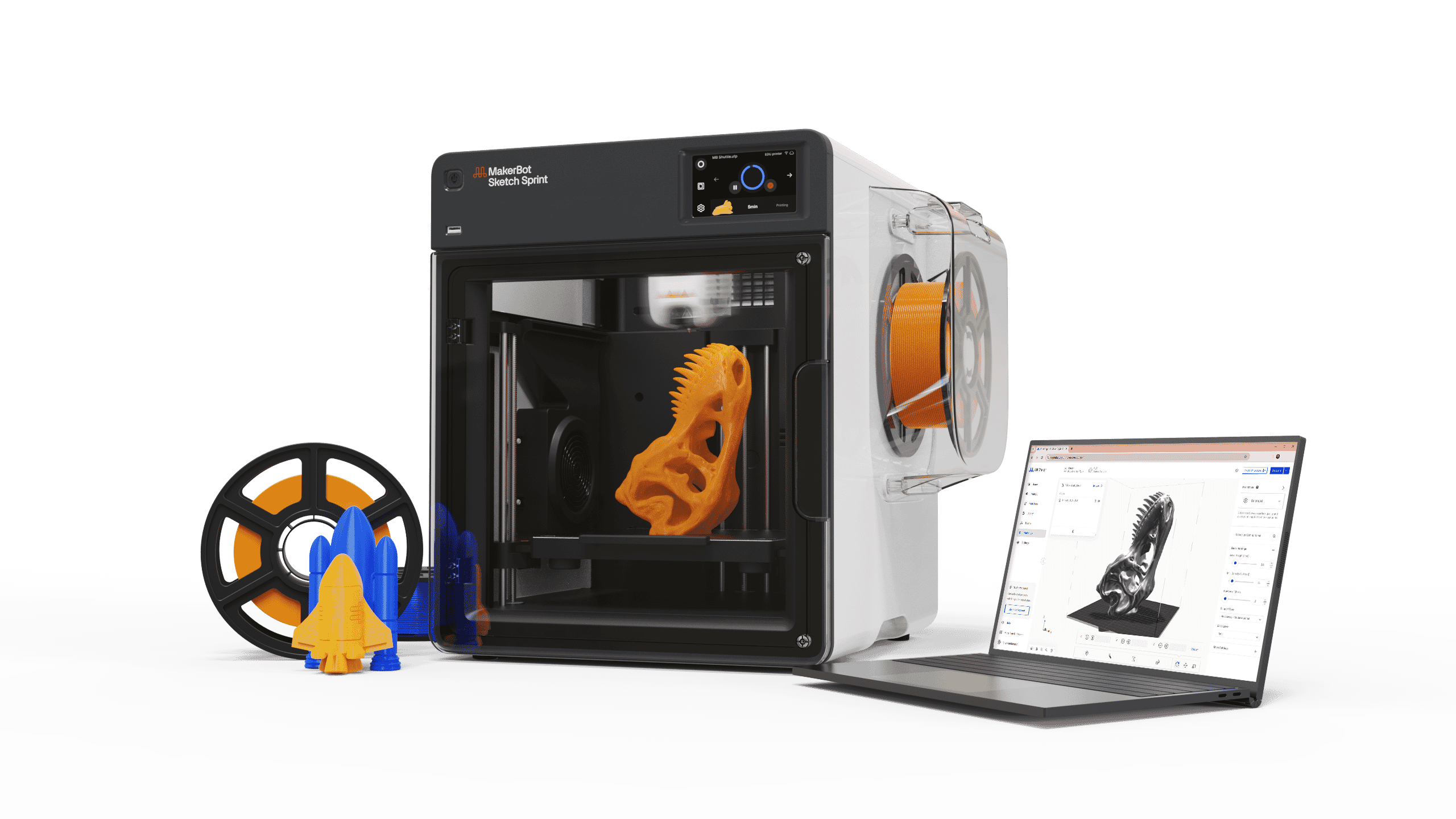

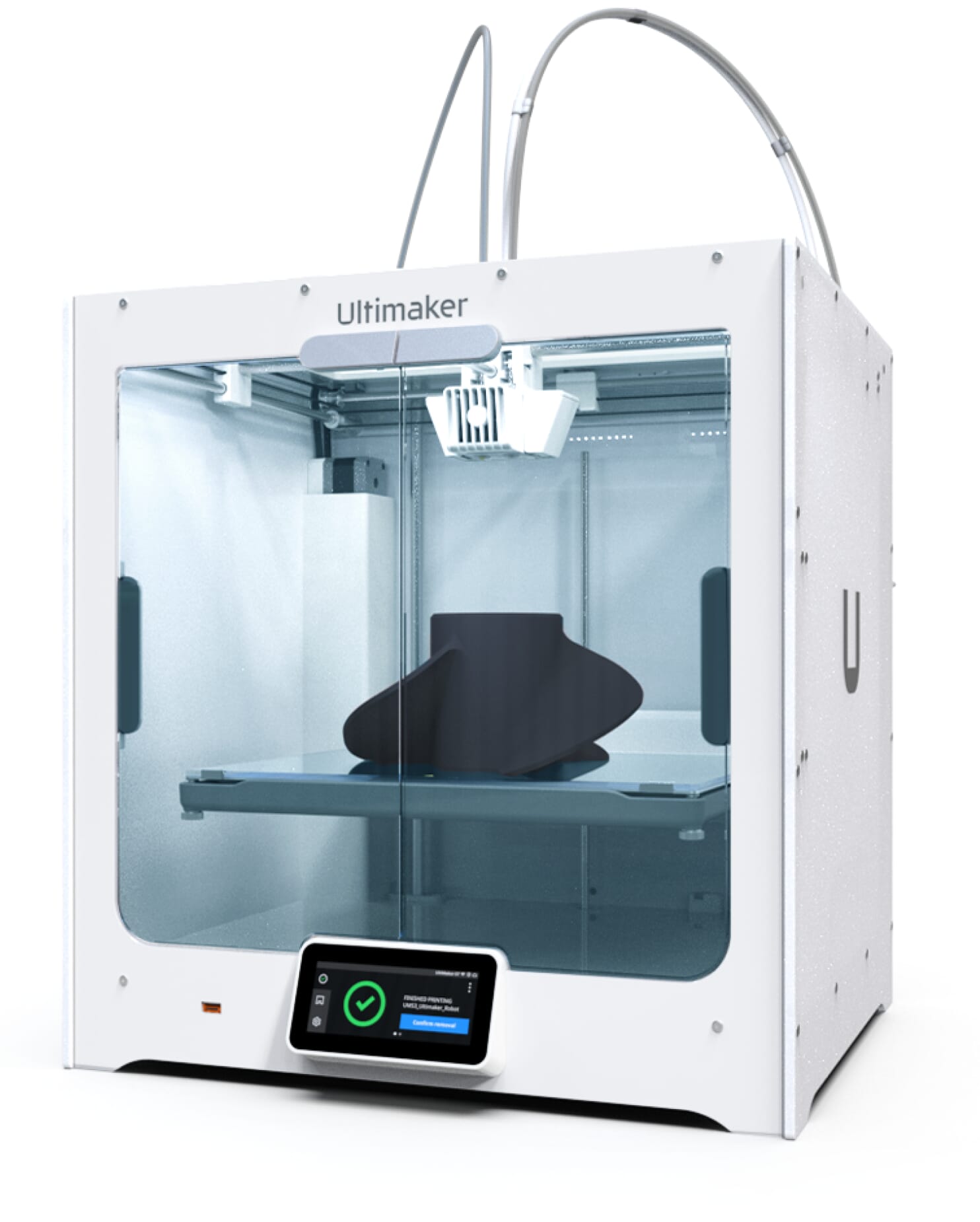

Printers best suited for the application of rapid prototyping

Rapid prototyping was the first and remains the largest application for 3D printing. Iterations from proof-of-concept through to functional prototype can all be 3D printed.

Whether outsourced or in-house, using 3D printers speeds up the rapid prototyping significantly through removing traditional bottlenecks in tooling and/or shipping. Rapid prototyping can also increasingly be done using the same 3D printing technology as will be used for the final product.