World leading software company Autodesk, invest in Stratasys 3D Printing solutions

Autodesk are a widely known and world leading CAD software company with over 35 years’ in the industry.

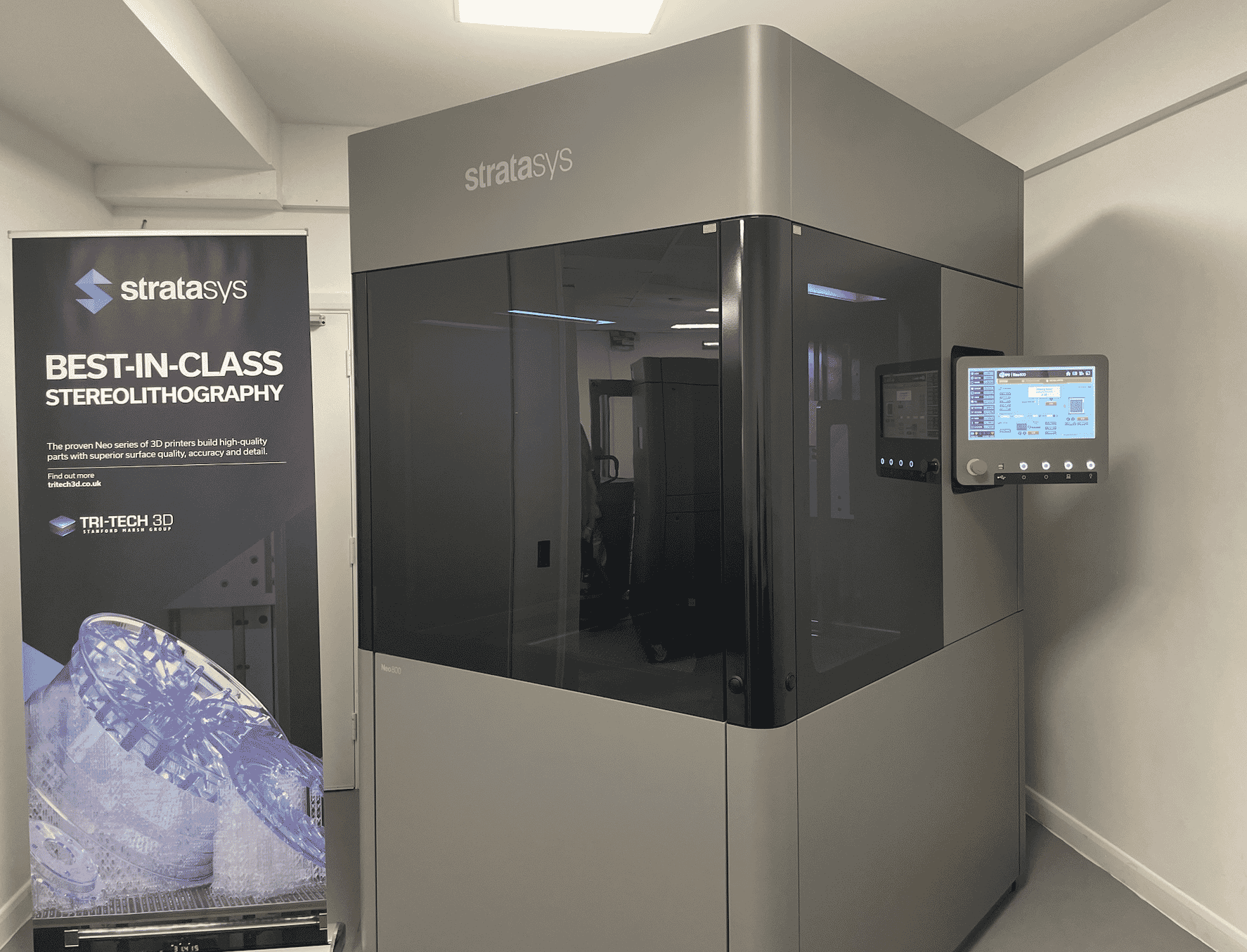

The Autodesk Technology Centre in Birmingham is home to some of the world’s state of the art manufacturing technologies, including CNC machines, Robotic solutions, state of the art 3D scanners and world leading 3D printers.

Autodesk were seeking a 3D printing solution that would aid their current manufacturing processes by providing an outlet to create strong and durable tooling, including Jigs and fixtures which would work harmoniously with their advanced machinery and stand the test of time. Tri-Tech 3D and Cadspec; both part of The Stanford Marsh group, were able to meet this requirement, providing the Stratasys Fortus 380 machine which is able to create complex parts more efficiently and effectively than any other FDM machine on the market. The wide range of strong thermoplastics available on the Fortus 380 meant this 3D printer was ideally suited to meet Autodesk’s manufacturing needs.

The facilities at the Autodesk Manufacturing Centre are second to none and those awarded with the privilege of viewing these facilities walk away with an instilled sense of wonderment and drive to be a part of this movement of design innovation. From robotic arms to 3D scanners that are able to pick up microns of detail, the centre really is the hub-spot for the future of making things.

Nick Hill, Operations manager at Autodesk comments:

Working with Tri Tech 3D has been a pleasure, from the initial selection of the machine through to delivery installation and training we couldn’t have asked for a better service, now the machine is installed it forms an important part of our development activities as we explore new processes and methods of manufacture for the Future of Making Things.