AP Racing Win New Business Utilising Stratasys 3D Printing

AP Racing, a UK based automotive manufacturer of performance brake and clutch systems for road and race cars, has been involved in every Formula 1 championship since 1967. Always striving to push the boundaries for its customers, AP Racing first established it’s in-house 3D printing capabilities more than 15 years ago for the prototyping of parts.

The Drive for the Perfect Sales Tool

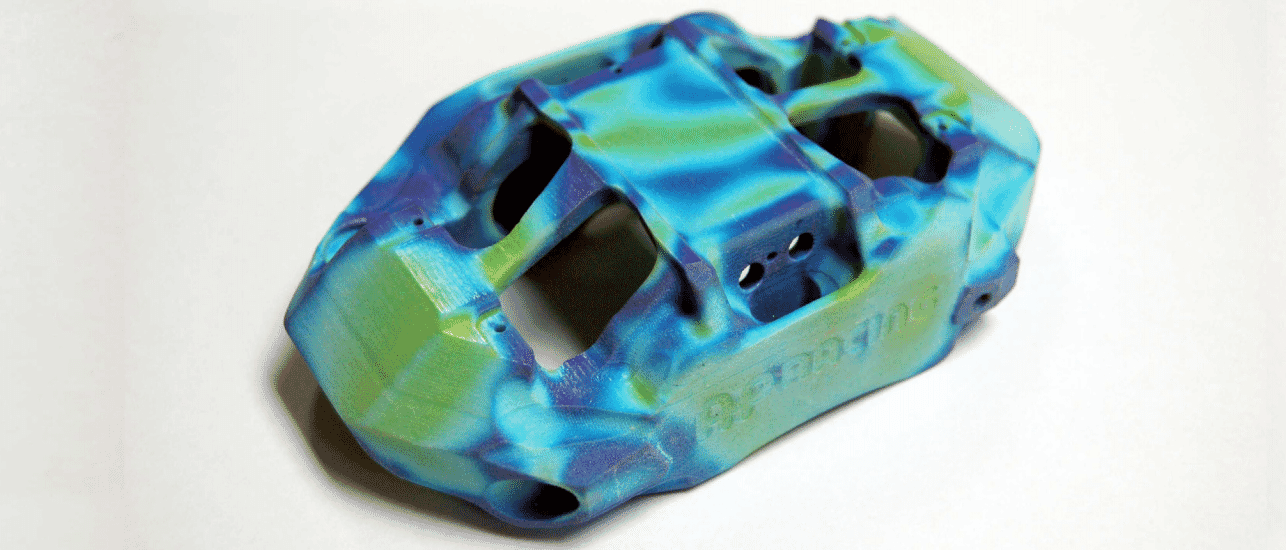

Competition became more aggressive and briefs became more advanced. Plus, designing a brake or clutch system is highly complex, with parts exposed to dynamic loads with high initial peaks. When designing components such as callipers, the AP Racing team completes in-depth finite element analysis plots for inspection. FEA breaks objects down into component elements to simulate how applied stresses will affect the material or design. This analysis is essential for determining how the brakes and clutches will best operate within the car, and how load will be distributed through the component.

To better showcase it’s solutions and set itself apart, AP Racing needed a technology that could simultaneously produce highly detailed, accurate, multi-colour prototypes, plus advanced multi-material tools.

Bringing Ideas to Life

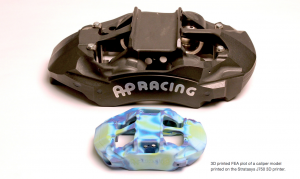

To help customers see the superiority of AP Racing parts, the company began producing prototypes using the Stratasys J750 3D Printer from Tri-Tech 3D. They are now able to 3D print their FEA plots to show potential customers the viability of its designs.

John Schoon, Senior Design Engineering at AP Racing commented:

Our team decided to create a 3D Printed model of the FEA plot for a clutch component. The J750 enabled us to produce a multi-material, multi-colour 3D model of the entire FEA plot of a clutch basket. The resulting model was so accurate, and so vivid in colour definition, that the team instantly understood the design decisions and placed an order.

Putting Efficiency in High Gear

In the past, AP Racing had to machine brake calliper prototypes, which was expensive and required significant lead time. Now, with it’s in-house J750, a prototype calliper can be produced in only 24 hours, a dramatic time saving with sacrificing accuracy. They also gained efficiency by using the J750 for innovative and advanced tooling applications. Almost every tool AP racing creates is a one-off, and the team used to rely on external suppliers, which often resulted in high costs and lengthy lead times of several weeks.

Production time and costs were also lowered with AP Racing for laster etch fixtures. Every laser etch fixture is highly complex, so having customised fixtures with precision positioning for repeatability is invaluable. Using traditional methods was costly, so Schoons team developed a 3D printed customised plastic model that helped speed production while only costing the company £100.

More Checkered Flags to Come

The advanced capabilities of the J750 are helping the future look bright for AP Racing. John Schoon sees great things ahead for the companies product development. He commented:

Needless to say, given the extent to which this technology is now integrated within our processes and the quantifiable benefits that we are enjoying, I can certainly envisage a greater use of it in the future

For further information about the J750, or how Tri-Tech 3D can help bring your products to market faster with a Stratasys 3D Printer – please get in touch.