Italdesign utilises the J750 for marble-effect interior parts

Founded in 1968 in Moncalieri, Italy, Italdesign is best know for it’s automotive design work for both concept and production cars. At the Barcelona division, the R&D team has built a strong reputation for it’s creative design techniques and deployment of innovative technologies to bring their concepts to life.

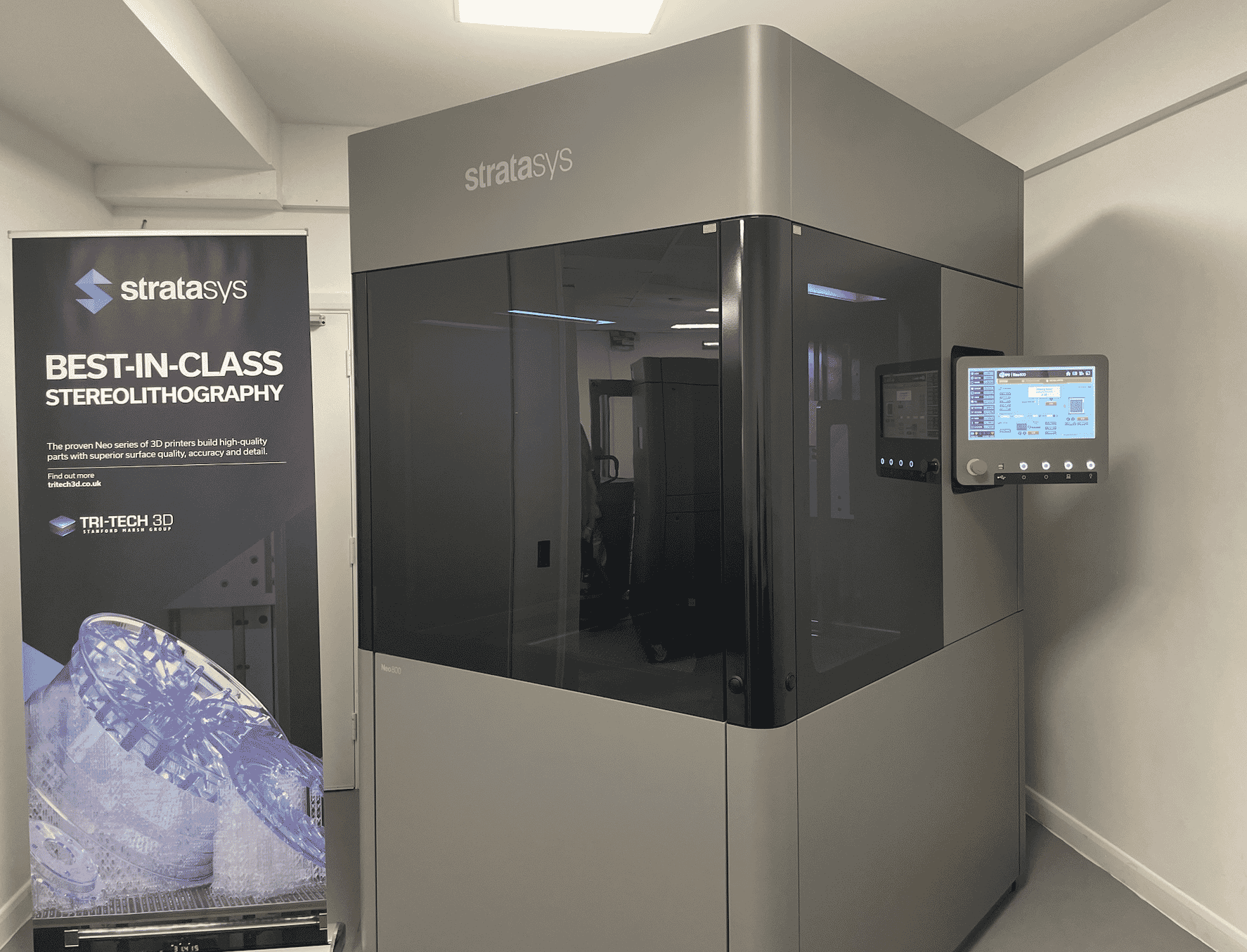

In order to push the boundaries of innovation for every vehicle designed, the R&D team leverages a number of technologies – with Stratasys additive manufacturing at the forefront. This includes a wide range of PolyJet and FDM 3D Printers.

Having been a satisfied customer for over eight years, Italdesign recently approached Stratasys local partner to purchase a J750. The added capabilities have made an immediate impression.

Turning Impossible Concepts Into Reality

Daniel Agullo – General Manager at Italdesign and his team were challenged to construct the companys 2019 concept car, the Italdesign DaVinci, in time for its inauguration at the Geneva Motor Show. The idea behind the DaVinci car is to revive the best of Italian elegance, integrating different luxury materials and textures within the interior that reflect the avant-garde style of the outer body.

Having explored a number of the ways in which this material sophistication could be achieved, the use of marble had strong appeal due to its elegant appearance and finish. However, producing such parts in time for the show using the traditional stonemasonry process was not possible.

Agullo explained…

We identified the key areas of the vehicle interior we wanted to produce in marble – the central console, air conditioning diffusors and door inlays – but quickly realised that we couldn’t use traditional techniques to achieve the marble finish in the remaining timeframe we had ahead of the Geneva Motor Show.

To overcome these obstacles, Italdesign looked for technology alternatives capable of providing an ultra-realistic imitation marble, including the colour nuances and feel – all within the tight deadline. Having tested several possible solutions, the team turned to the J750 and it’s unique capability to 3D Print marble effects and textures directly onto parts. To achieve this, the team designed each part via CAD and using a render software digitally overlaid the marble texture onto the part to deliver the desired effect. Once the design was validated, the final file was uploaded to GrabCAD Print to enable printing.

Reimagining The Cars of Tomorrow

Italdesign intends to use it’s J750 to influence future car designs in a similar vein to the marble effects implemented within the DaVinci concept car. Agullo explained that the J750 opened their eyes to the possibilities of ultra-realistic prototyping and that the possibilities are endless, giving their designers the full freedom of imagination, knowing that they can bring their ideas to life.

For further information on the J750 and how you can implement full colour 3D Printing in to your business, get in touch with our team: info@tritech3d.co.uk or call us on 01782 814551