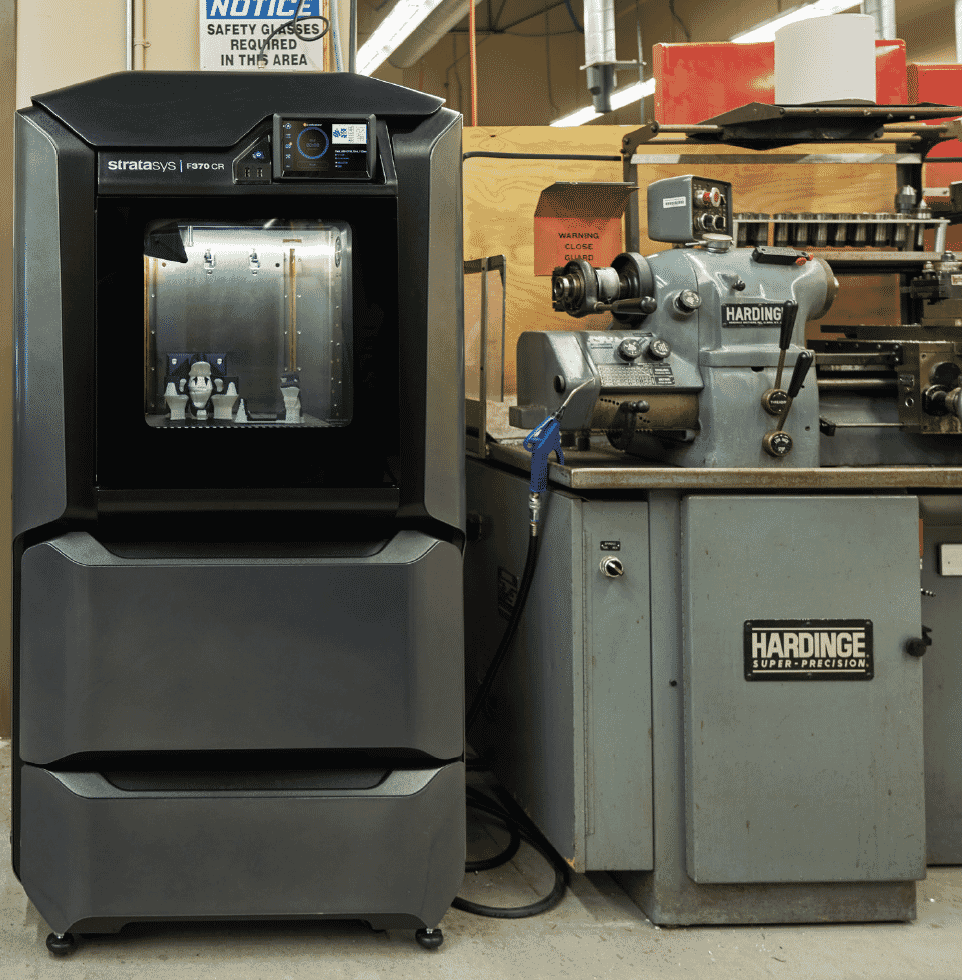

Stratasys F370CR - high strength composite 3D printer

The Stratasys F370CR composite printer is built on the same platform as the proven F123 Series, with a verified 99% uptime and a 99% dimensional repeatability performance. Material tuning – optimising print parameters using over 220 measurements – ensures consistent material performance across all resolutions and successful print results.

Built to last

Built-in durability starts with hardened components and print heads to ensure longevity using abrasive composite materials. Sealed filament bays reduce material moisture exposure to maintain stable material mechanical properties, so printed parts meet strength specifications. A fully heated build chamber enables higher strength between layers than other printers in this class that use only a heated build platen.

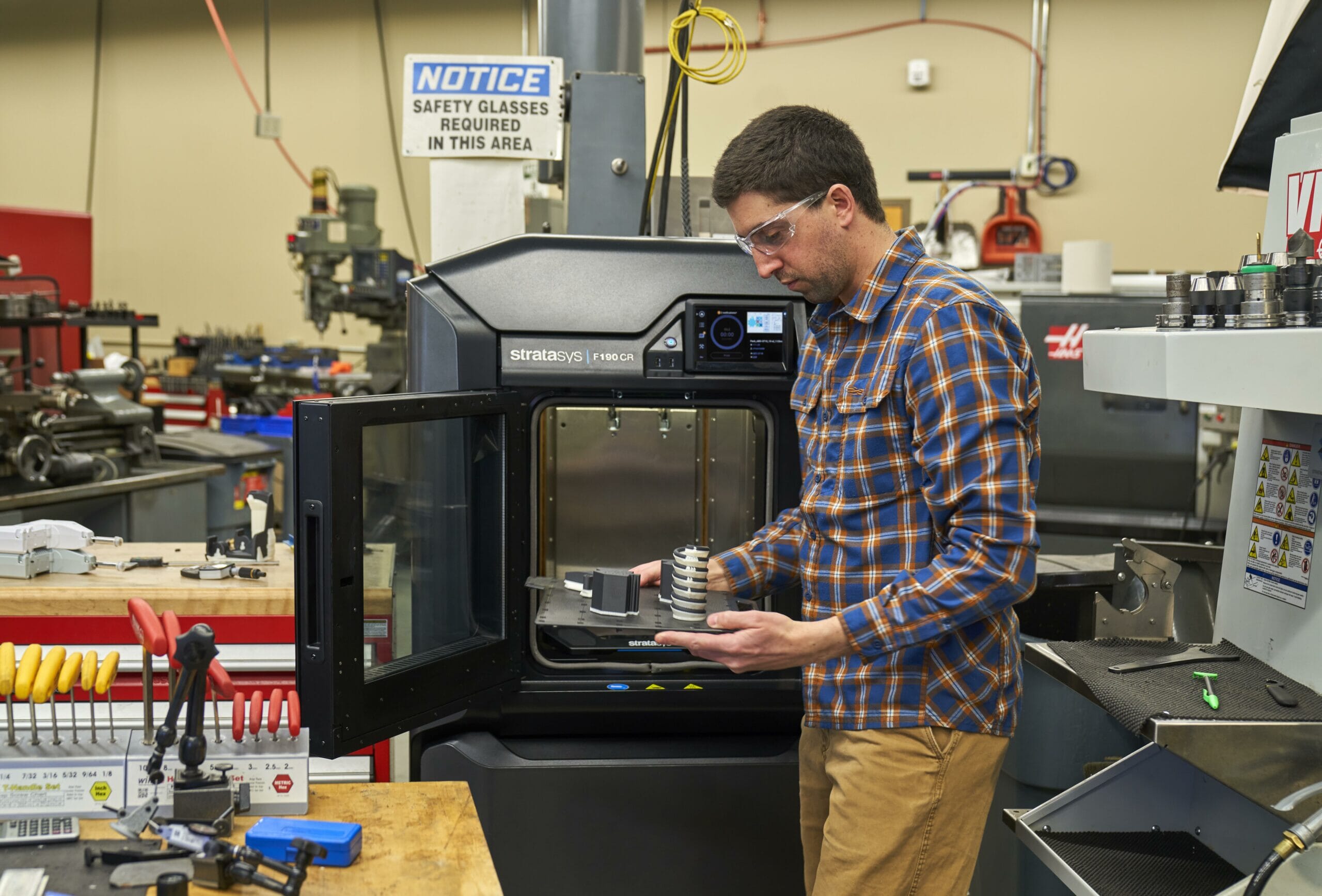

Easy to operate

You don’t need special training or highly skilled technicians to operate the F370CR. Job setup simply involves importing the part’s CAD file using GrabCAD Print™ software and initiating the print. The printer requires no further oversight until the job is done.

Looking for pricing?

To get you the most accurate and up-to-date pricing, it’s always best to contact our team either by phone or the enquire now form provided. We will be able to break down all the figures for you and include any additional cost for post-processing equipment, training and support (if required). And not just capital costs either, as we have many options to help you acquire the best 3D printer, which include finance. Lease rentals will allow you to spread the cost of your investment over 3-5 years, from as little as £899.00 +VAT per month for a mid-level FDM printer.

The F370CR includes an auto-changeover feature, so you won’t have to interrupt a build to refill material. When a refill is needed, it’s as easy as dropping the canister in place and inserting the filament into the feed slot. The printer takes it from there. Print head changes, if needed, involve only a quick snap-out/snap-in step.

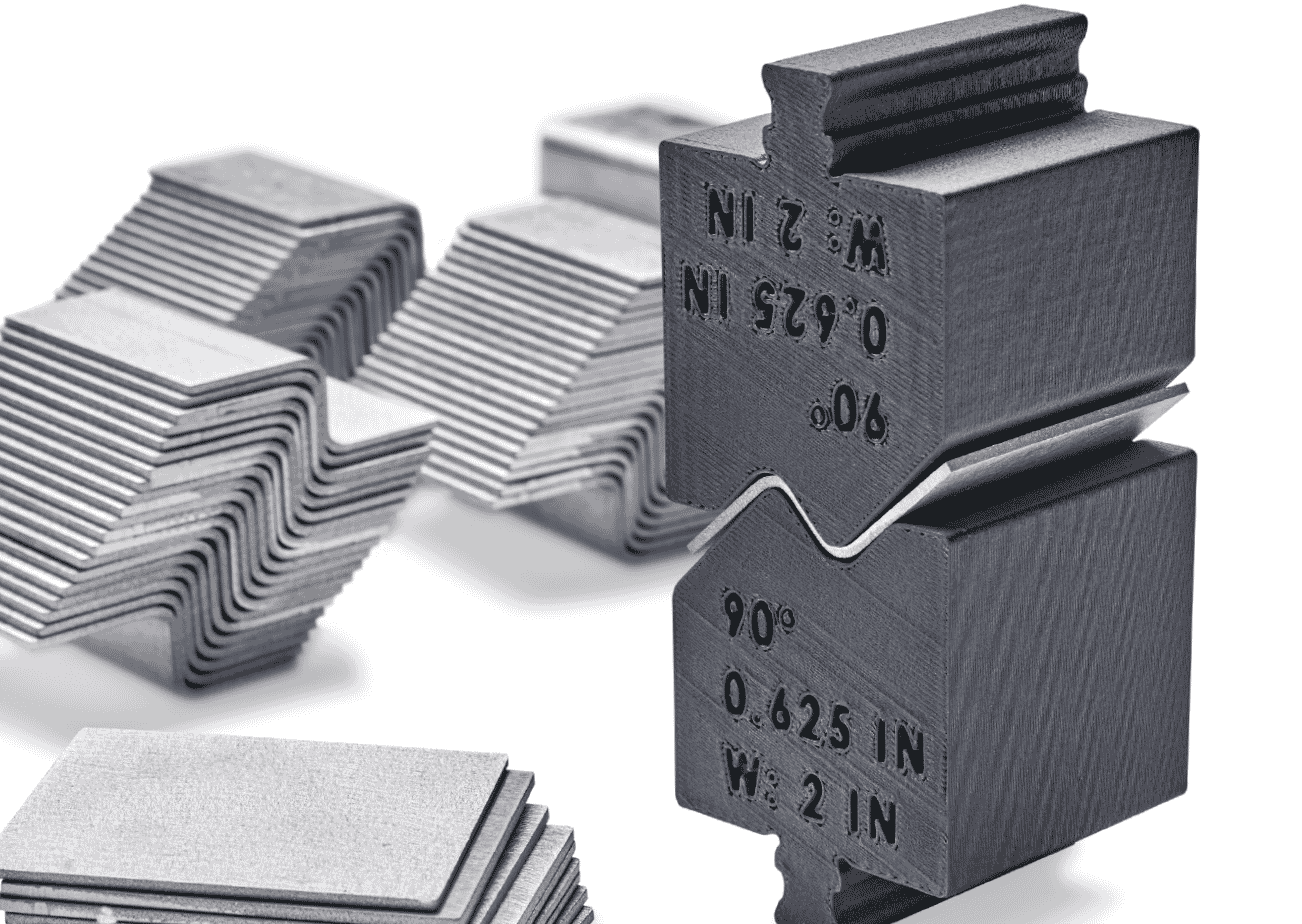

Open materials

The F370CR offers application versatility by operating with a range of thermoplastic materials. In addition to high-strength composites, the F370CR gives you the flexibility to print with other engineering thermoplastics to cover more use cases. This multi-material capability offers the convenience of printing different jobs in different materials. There’s no need for separate printers dedicated to composite and non-composite materials.

- Build Size: 355 x 254 x 355mm

- Layer Thickness: 0.127mm – 0.508mm (0.005inch – 0.020inch)

- Software Compatibility: GrabCAD Print & Insight

- System Size: 1626 x 864 x 711mm

- Power Requirements: 100-132V/15A or 200–240V/7A. 50/60 Hz

- Material Delivery: 4 material spool bays, 2 for model, 2 for support located in a drawer on the front of the unit

- Accuracy: Parts are produced within an accuracy of +/- .008 in. or +/- .002 in whichever is greater

-

ASA

Read MoreYour go-to FDM thermoplastic in 10 colours

-

TPU 92A (Elastomer)

Read MoreProduce large and complex Elastomer parts

-

ABS-CF10

Read MoreCarbon Fiber Filled ABS With Unique Stiffness & Strength

-

PC-ABS

Read MoreHigh-impact engineering thermoplastic

-

Lubricious non-marring material

Read MoreDiran 410MF07

-

ABS - ESD7

Read MoreABS thermoplastic with static dissipative properties

Leasing 3D Printers

If you’re looking to 3D printer leasing, Tri-Tech 3D provide direct rental contracts on our full range of 3D printers, which can include post processing equipment and extended warranty, making your investment into 3D printing both affordable and help plan your annual expenditure.

How do I lease a 3D Printer?

The process is quite simple! First, you’ll need to undergo a credit check. This can be done quickly, usually within 24-48 hours. If you’re a new start-up company or sole trader, it may be more difficult to obtain finance, but deposit payments and directors guarantees can help. Talk to a leasing company to get a pre-proposed finance plan without any obligation. Once approved, you’ll know what value technology you can consider.

Funding in the most part, is provided by our sister company Stanford Marsh Finance (a division of the Stanford Marsh Group) or via our numerous strategic finance partners/brokers.

Rates are frequently checked to ensure competitiveness in the market place and you will find our terms highly attractive. With options such as fixed term contracts, step rentals which make payments lower in the earlier years allowing time to grow the use from your new device. Or deferred payment, enabling you to benefit from the technology ahead of when you start paying.

Why lease 3D Printers?..

Not only can leasing be financially beneficial to companies, but it can also give you the ability to remain ahead and current with technology. It also means your entry point to utilisation of a professional 3D printer is far more affordable than you may think – a professional 3D printer from as little as £299 per month, (including a wash system and 12-months support).

Furthermore, if like many companies today you are outsourcing 3D printing via a 3D Print Bureau, you are already spending an amount each month that when converted to a lease, could represents an in-house option at no extra cost (savings possibly). Either talk to one of our team, or send us details of your average spend and we can help provide an ROI report.

In addition to our excellent rates, as an end user dealing directly with one vendor for finance, equipment and after sales care, your rental agreement will provide you with a future flexible upgrade path. We’ve enabled companies to acquire new technology prior to the completion of the minimum rental period, without the usual high termination figure charged by outside finance agencies.

All finance is subject to approval and none of the solutions detailed above are guaranteed to suit all scenarios. What we can promise however, is we will do our utmost to make the finance of your 3D Print solution as affordable and easy as possible.

What are the main benefits of leasing a 3D printer?

Leasing a 3D printer has many benefits compared to outright purchase. Leases are usually affordable, good for cashflow, and allow you to invest in more equipment without large amounts of money upfront. If you already outsource 3D print work, leasing can help you bring production in-house and may improve workflow and protect your intellectual property. Additionally, there are well-documented taxation benefits to companies in regard to leases.

When to lease VS buy a 3D printer?

When deciding whether to lease or buy a 3D printer, consider your needs. If you have a proven requirement and plan to run a system to its end-of-life, outright purchase may be best. However, if you want to keep your options open and stay up-to-date with new technology, leasing provides flexibility to upgrade at the end of a minimum leasing period.

I’m not ready to lease or buy a 3D printer – is a service an option?

If you’re not ready to lease or buy a 3D printer, outsourcing to a print bureau could be a great option. Companies like 3D Print Bureau offer access to a team of experts running a variety of professional 3D printers in different technologies. This allows you to pay as you go for the end part until your volume hits a level where bringing production in-house makes sense.

If you are interested in further information, please contact us.

Stratasys F370CR 3D Printer Brochure Downloads

New to 3D

Printing or looking

for some support?

- Call: 01782 814551

- Email: info@tritech3d.co.uk

Why do companies buy a 3D Printer?

That’s a good question and asking it today we think has changed significantly from had it been posed 15-years or so ago. Traditionally a 3D Printer provided solutions to Rapid Prototyping, a functional model to prove fit, form & function, or to convey a design intent to a client (better than a 2D drawing, or even rendered 3D imagery).

And when that was the end requirement, the focus was more on choosing a manufacture who built reliable devices that print right first time and in the professional sector, where repeatable accuracy could be achieved.

Why do people buy from Tri-Tech 3D?

We could say we are a well-established company, part of a larger group, with years of industry experience, six UK locations and our own finance company. All of which is true, but also sounds familiar to what the others may say and in some cases, a “so what”.

Why we think our customers buy from Tri-Tech 3D and not just once, is we are a ‘customer centric’ business who treat people how we like to be dealt with ourselves. We want to know what you will get out of a system investment, we want to help drive that adoption and we want to see customers being successful.