High performance lighting company utilise FDM 3D printing

Founded in 1935, J.W. Speaker Corporation makes high-performance lighting for automotive, powersports, transports, and industrial vehicles. The company specialises in developing innovative LED and emerging lighting technologies for OEM and aftermarket customers worldwide.

Challenge

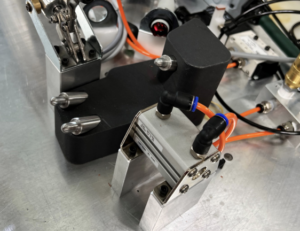

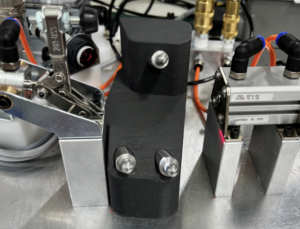

The manufacture of a snowmobile light fixture required a leak test to validate its watertight capability. These tests employ fixtures that must withstand a 100-pound force as air is evacuated from the light housing to ensure a proper seal. Custom fixtures are typically machined from aluminium, but this involves procuring the raw stock and CNC machining the tool. Although this solution works, engineers desired a faster approach for manufacturing and deploying the device into production.

Solution

Instead of machining, J.W. Speaker tool designer’s 3D printed the fixture using FDM® Nylon-CF10 carbon fibre material, a nylon-based composite thermoplastic filled 10% with chopped carbon fibre. The result is a much stiffer and stronger material capable of more demanding applications. Nylon-CF10 is available on the F370®CR composite printer, which includes other composite materials and engineering-grade polymers.

Impact

3D printing the tooling fixture allowed J.W. Speaker to reduce the tool production time by approximately 80%, from two days to 10 hours. The Nylon-CF10 and F370CR composite printing capabilities also enabled the freedom to design the tool as needed, without the constraints of traditional machining. This approach provides a more agile tool design process, allowing changes to be implemented quickly.