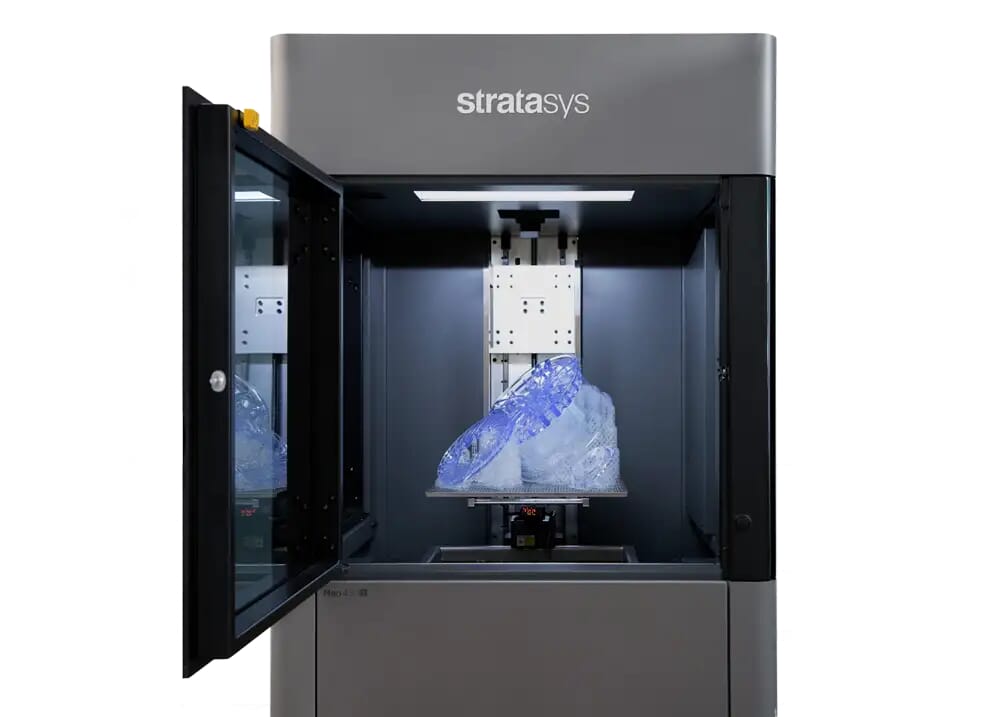

Stratasys Neo 3D printers

Master SLA 3D printing with Stratasys Neo

What is SLA 3D printing?

Also known as resin 3D printing, Stereolithography (SLA) is the most popular of the vat polymerisation technologies – a bracket which also includes Digital Light Processing (DLP) and Liquid Crystal Display (LCD). The near-infinite variables – from light source and build platform to the properties of the photopolymer resins used with the printer – can give a spectrum of different results and excel across countless applications.

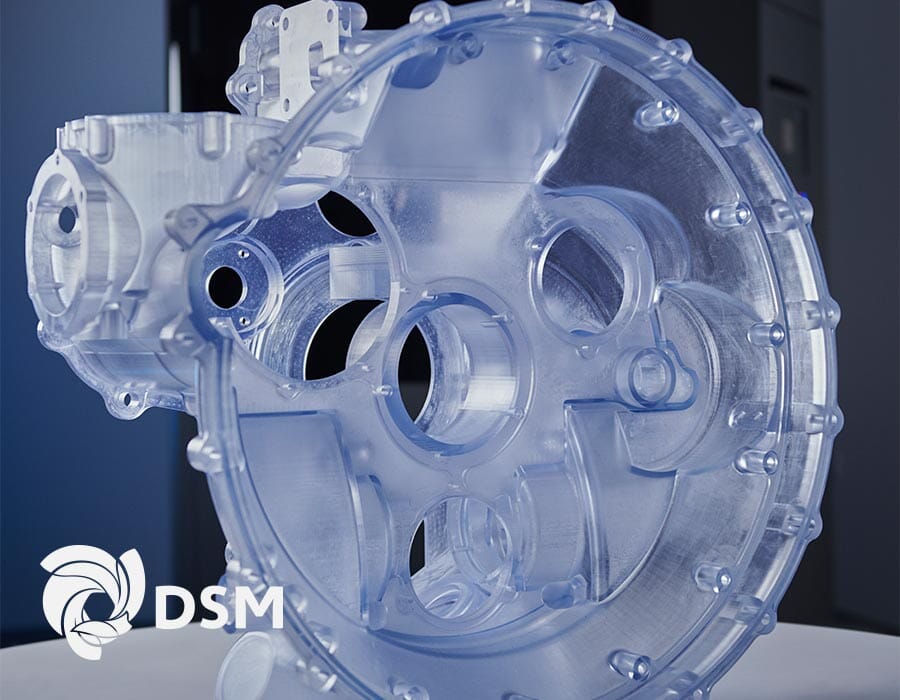

The majority of SLA users are attracted by the ability to create accurate, watertight and isotropic prototypes – not to mention the means to produce components with smooth sidewalls, exacting detail and complex geometries, while achieving tight tolerances with a layer thickness from 50 to 200 microns. SLA has become a byword for accuracy – and that reputation has only been enhanced by the Neo range.

Stereolithography Printing Benefits

-

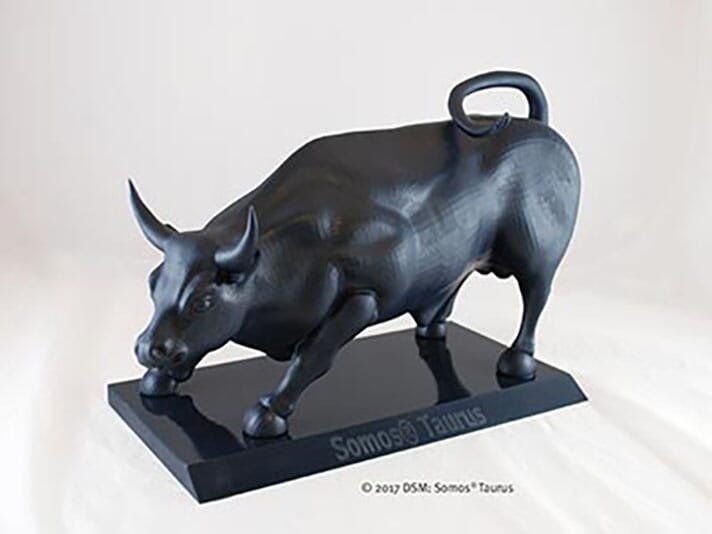

High Precision & Fine Detail PrintingThe extremely thin layers used in stereolithography, combined with its precise laser beam, make it possible to create prototypes with a highly realistic finish and intricate geometric shapes.

-

Wide Range of MaterialsStereolithography (SLA) 3D printing supports a wide range of materials, including flexible, rigid, and transparent resins, making it versatile for various applications.

-

Reliable TechnologyExcellent hardware reliability due to simple 3D printer design and best-in-class components.

CASE STUDY

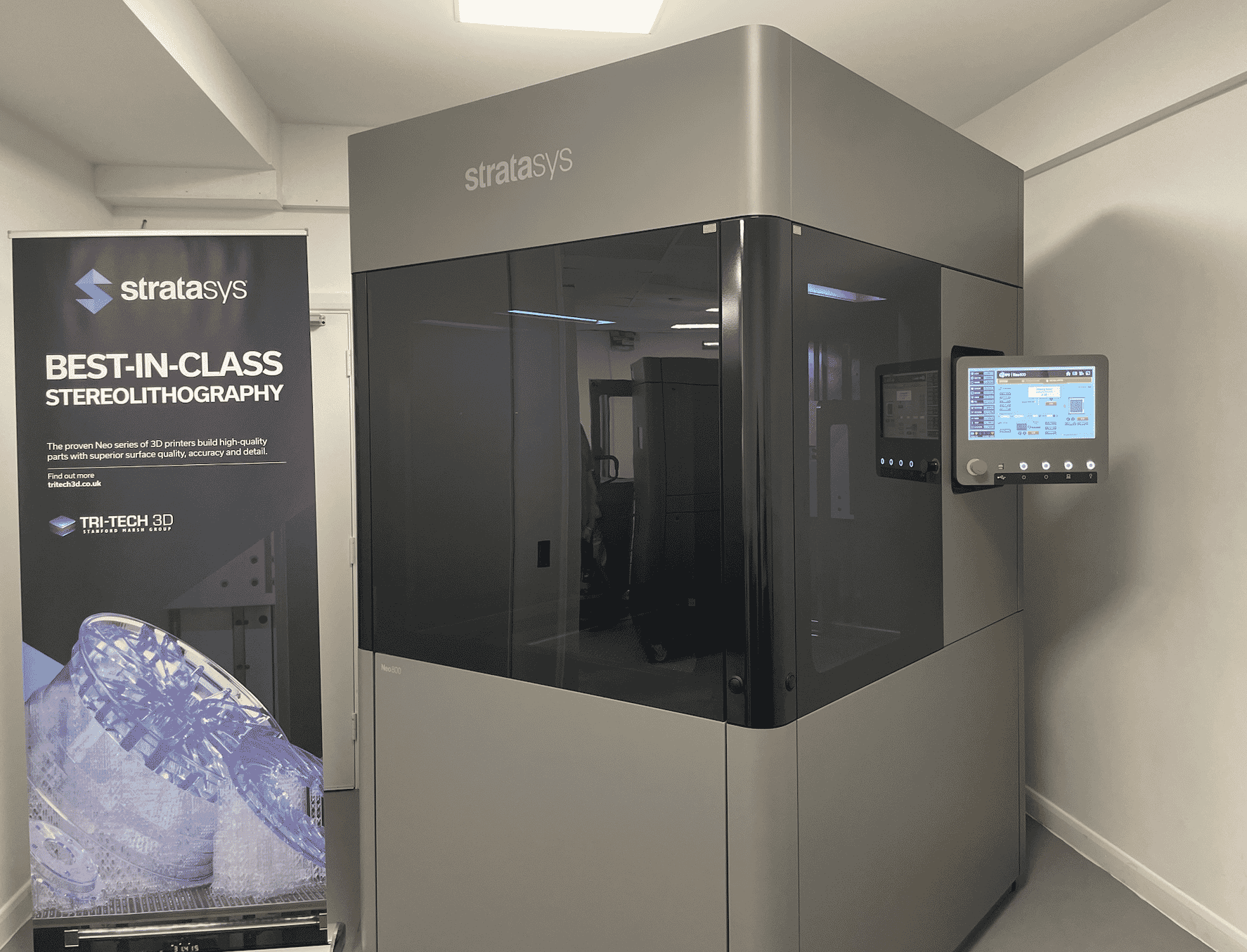

HPL sees instant return on investment with NEO800 system

High-quality, cost-effective automotive part production

Based in Coventry, HPL Prototypes specialises in the manufacture of bespoke show cars, with clients including prestigious brands like Bentley, Aston Martin, McLaren and Jaguar Land Rover. The company produces prototypes and concepts with different aesthetics for its clients before they enter full-scale production.

-

How does SLA 3D printing work?

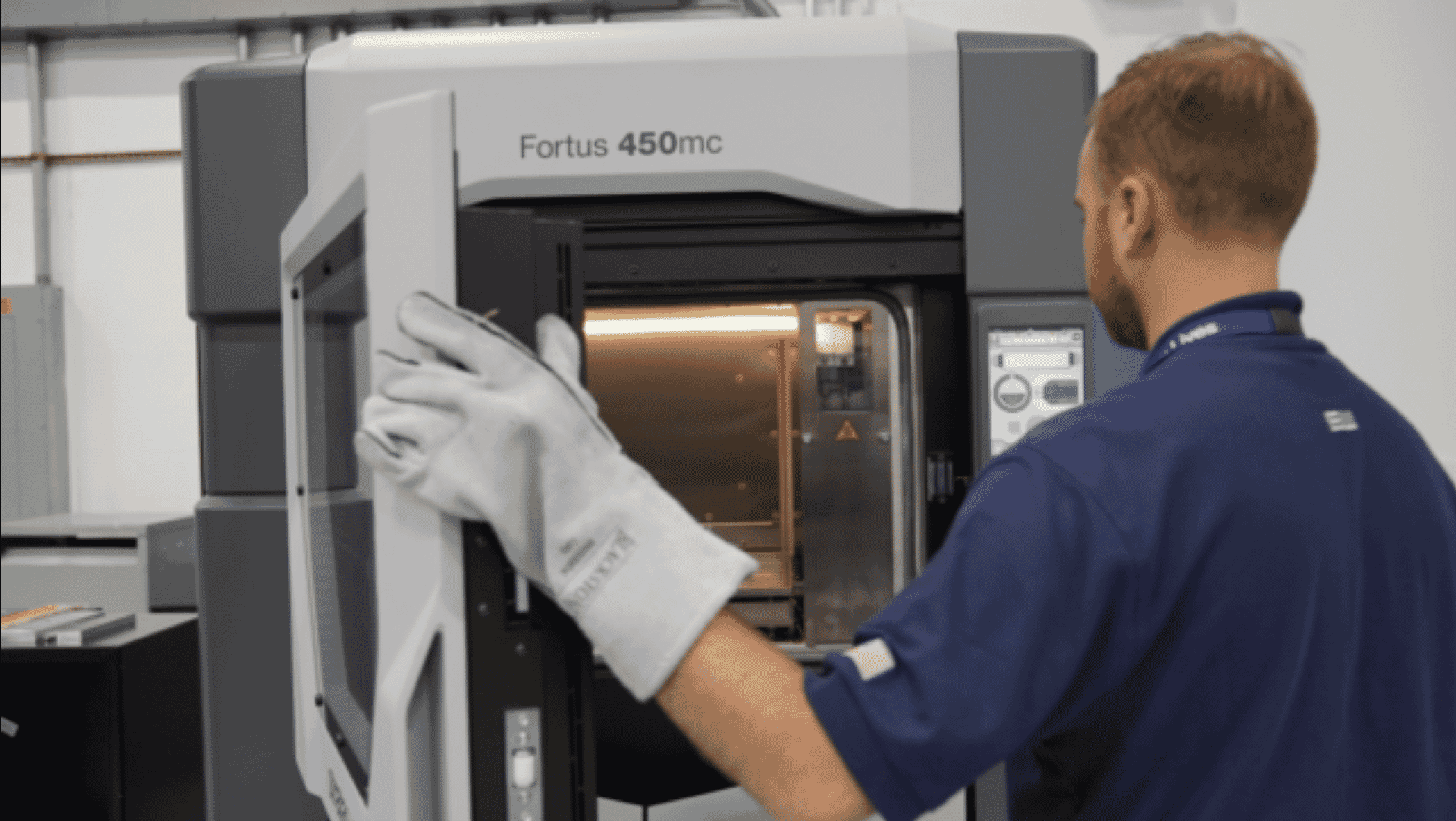

You don’t need a deep scientific knowledge of the technology behind your new Stratasys Neo resin 3D printer to get outstanding results from it. After all, this hardware is renowned for its ability to run like clockwork without human intervention. But many clients are interested to learn more about the fundamental principles that make SLA different from other AM disciplines like FDM.

-

What are the advantages of SLA 3D printing?

There’s a good reason why SLA trailblazers like the Stratasys Neo feature in print labs around the world. From rapid build times and unrivalled precision to stellar finish and capacity for forensic dimensional accuracy, SLA not only delivers high-quality parts but massively reduces lead times (with a corresponding boost to the bottom line). Benefits of SLA include superior isotropy (FDM cannot match the consistent mechanical performance of these components) alongside watertightfulness (vital when an application demands predictable air or fluid flow).

-

Which applications is Stereolithography used for?

Thought leaders across the gamut of global industry use SLA technology to bring next-generation designs off the drawing board. From made-to-measure patient care in the dentistry and healthcare sectors to high-definition modelling for the film industry, resin 3D printers are now a mainstay of the most ambitious print labs.

-

What is the history of Stereolithography?

Open the history books and you’ll discover that SLA technology has been with us for the last half-century. The fundamentals reach back to the early-’70s, when Dr Hideo Kodama – an innovative Japanese researcher – developed the principle of printing layer-by-layer while using ultraviolet light to cure photosensitive polymers.

-

How do you achieve the best results with SLA printing?

To benefit from the flagship print quality for which SLA is renowned, it’s important to choose the right 3D resin printer and complementary materials (the Tri-Tech 3D team is always on-hand to advise on that front). But there are also a few golden rules to grasp, and these include an appreciation of support, curling and layer adhesion. Every time you print a component using SLA, you’ll also need to create an accompanying support structure, produced at the same time, in the same material (after printing, you’ll simply remove it). However, always remember to orientate the part so the most visually critical areas of the component don’t make contact with the support structure: this way you’ll be sure to avoid unsightly surface blemishes.

-

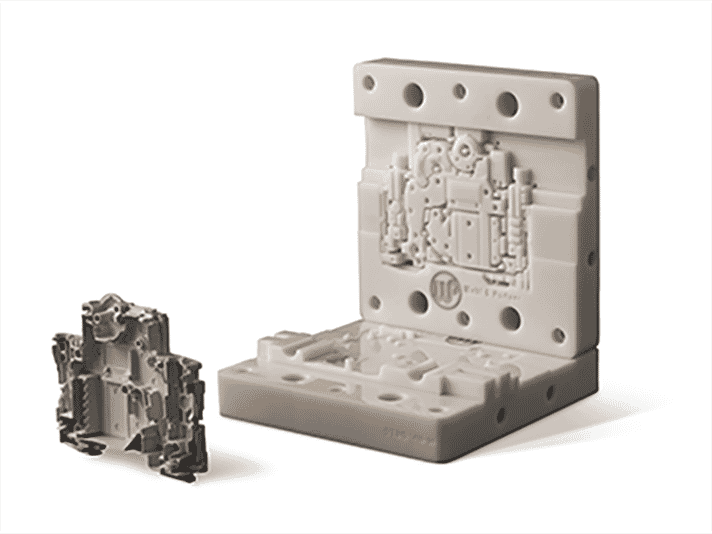

Which materials can used alongside an SLA printer?

When you choose a Neo printer, you’ll find the sheer breadth of potential materials will support practically any application as your business evolves. Faced with the choice of SLA materials offered by Tri-Tech 3D – whose properties include strength, flexibility, heat resistance and performance in extreme environments – it’s worth taking time to select the right liquid resin in order to optimise the final component.

-

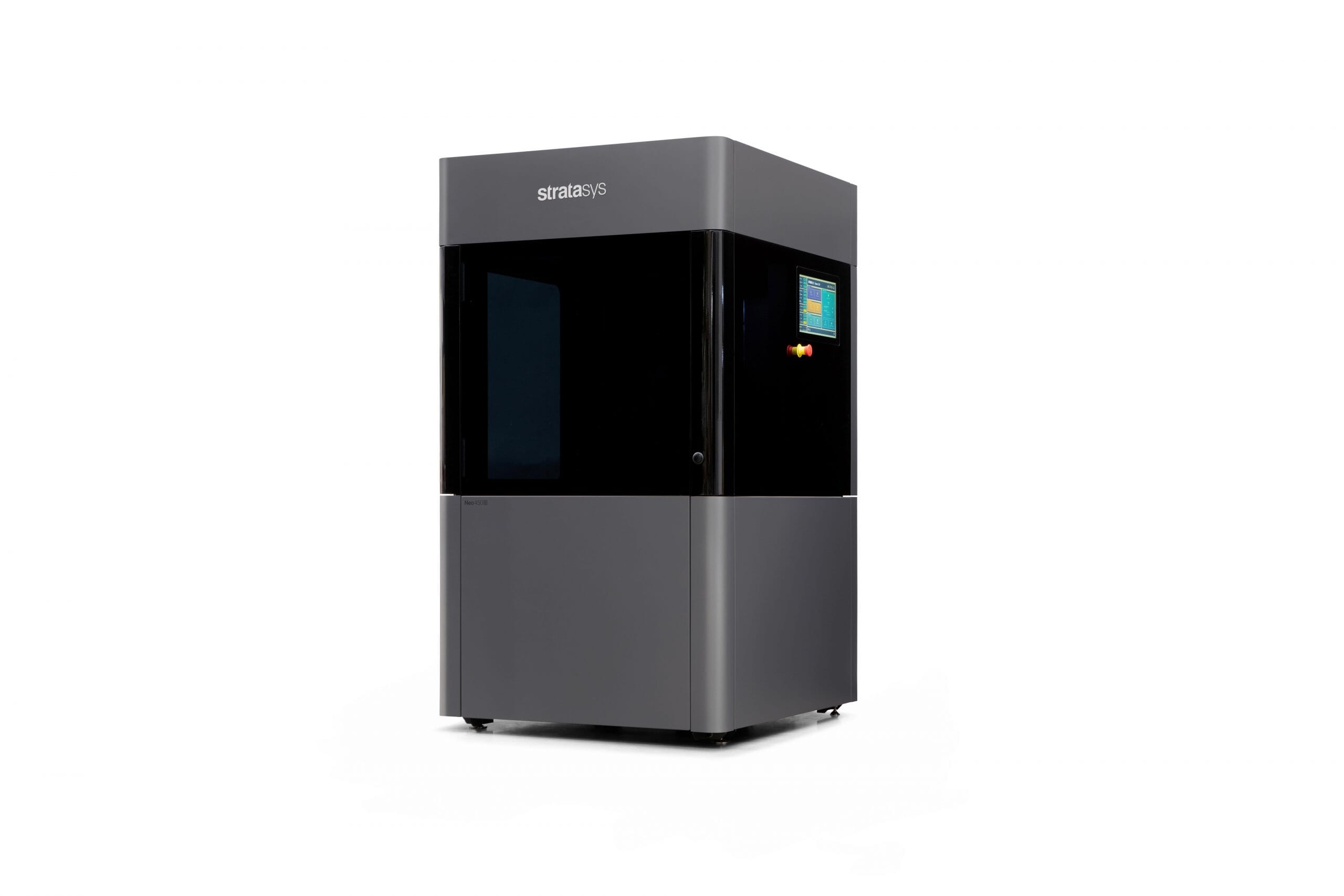

What's the difference between desktop and industrial SLA 3D printers?

SLA systems are available in two main formats: compact desktop units and industrial printers like the Stratasys Neo series. For undemanding applications, or when space and budget are limited, you might find that desktop printers get the job done. But if SLA is set to become a cornerstone of your business into the future, we’d certainly recommend investigating a professional resin 3D printer.

-

Should I choose an SLA 3D printer or FDM 3D printer?

Fused Deposition Modelling (FDM) printers work on a very different principle to Stereolithography, featuring a thermoplastic filament that is pushed through an extruder to create the component. At Tri-Tech 3D, we offer both FDM and resin 3D printers and always recommend that clients consider which format suits the project at hand (rather than worry about which technology is ‘better’).

-

How do I choose between the Neo 450e, 450s and 800?

Since the ’80s, Stereolithography hardware has grown ever smaller and more affordable (even as the performance and features have advanced at pace). As an official partner of Stratasys, Tri-Tech 3D has found that between the three Neo models, this acclaimed range ticks the boxes of the most discerning businesses. The Stratasys Neo 450e is a great entry point into this advanced family of SLA printers, offering a compact platform (450 x 450 x 400mm) that lets users produce small-to-medium parts with consistent accuracy and repeatability. Invest a little more for the Stratasys Neo 450s, meanwhile, and you’ll benefit from components produced up to 40% faster, alongside standard and high-definition modes.

Most popular NEO ® SLA Printers

New to 3D

Printing or looking

for some support?

- Call: 01782 814551

- Email: info@tritech3d.co.uk