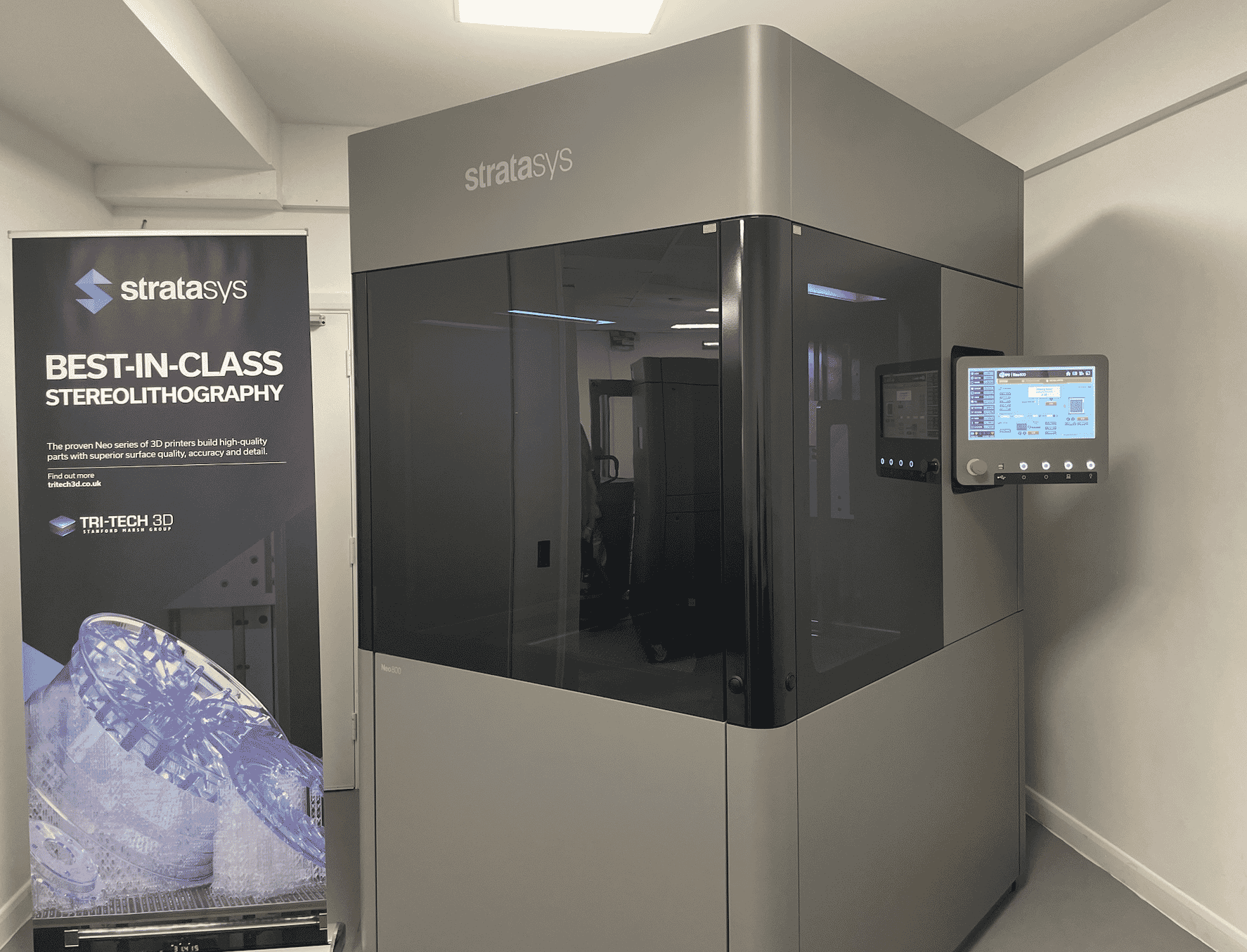

Tri-Tech 3D is the UK's leading distributor and supplier of Stratasys & One Click Metal 3D printing systems

Our roots as a true engineering company with bias on technical ability and support have helped us to become the most reliable and well-respected business partners for Stratasys, One Click Metal and XJet 3D printers throughout the UK and Ireland.

You will find our staff friendly, knowledgeable, and conversant with all the latest developments relating to the handling of 3D content.

We look forward to discussing your specific requirements with you.