GKN Aerospace reduces costly production downtime with 3D printed tools

GKN Aerospace (GKN) is a leading multi-technology tier 1 aerospace supplier, serving over 90% of the worlds aircraft and engine manufacturers. In the last 30 years, GKN aerospace has also earned a reputation as a leader in additive manufacturing technology for the commercial, military and space markets.

Reducing costly production downtime with 3D printing

The team at the companies Filton manufacturing site is responsible for producing and supplying production tools and prototypes to multiple areas of the business. When faced with the need to reduce costly production line downtime, as well as deliver the most fully-functional, ultra-realistic prototypes possible, GKN’s additive manufacturing polymer specialist Rachel Trimble, turned to 3D printing.

For GKN any halt in the production line is a very costly disruption. For example, when a tool breaks that has been traditionally manufacturing, replacing it results in a very long lead time and incurs high costs. Engineers would typically have to wait weeks for a new tool, a downtime they could not afford.

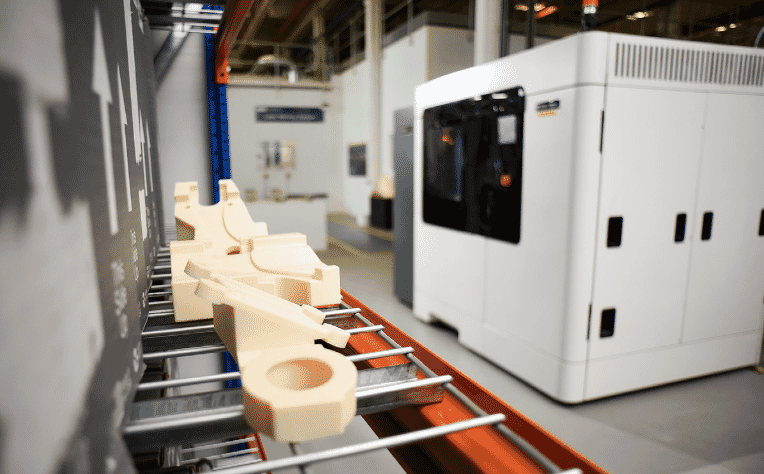

In one case, the GKN engineers actually 3D printed small tools so as to create protective masks used when processing metal parts. Because the masks weren’t commercially available, the backlog of parts needing processing grew. But the ability to quickly print the tools in the correct size to make the masks enabled several parts to be processed at once, alleviating the backlog.

Customised, optimised, revolutionised

It’s not just AM’s time and cost savings that GKN enjoys, it also beleives that one of it’s key benefits is the creative freedom that it gives users. Previously, GKN engineers were limited by the economic & physical constraints of traditional manufacturing.

According to GKN creating optimised, accurate 3D printed tools without being restricted by size or shape has enabled them to tailor tools to specific jobs and improve the functionality of their operations. In certain cases, GKNs engineers report a dramatic reduction of 40% in concessions, and some jobs even dropped from two operators to one. To achieve these goals, GKN relies heavily on their Stratasys Fortus 900MC 3D printer.

Ultra-realistic, fully-functional prototypes

Besides tooling, GKN regularly uses it’s Fortus 900 for rapid prototyping. One of it’s most successful cases was the creation of a fully-functional aircraft windscreen housing. The team was on a tight deadline to produce the housing for a product launch event but it was still incomplete just days before the launch.

In a matter of hours, we were able to produce a prototype of this windscreen housing on theFortus 900mc. The prototype produced was so realistic and so accurate that the launch team was not only able to go ahead with the event but the feedback received confirmed that the 3D printed housing was almost indistinguishable from the real thing.

To the future

Trimble anticipates a greater move towards the use of FDM additive manufacturing for high-value, flight-critical, end-use composite parts.

By harnessing Stratasys additive manufacturing for tooling and prototyping, we are enjoying both timeand cost savings, among other benefits, all while simultaneously preparing ourselves for the future!