Discover the latest Stratasys material releases in the FDM range

With a wide variety of materials available and a strong reputation for being a market leader in 3D print hardware and consumables, Stratasys are already highly successful within the Manufacturing, Automotive and Aerospace industries. However, with the recent release of 3 brand new materials, they’re set to further secure business within these markets.

Maintaining a focus on developing the current FDM range, these all new materials deliver improved performance, more capabilities and improved functionality in challenging or highly regulated environments. Check out the new additions to the FDM range below…

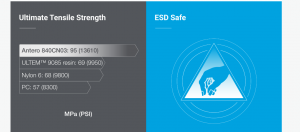

Antero 840CN03

Adding to the Antero family, Antero 840CNO3 is a high performance FDM filament that’s based on Kepstan Pekk. Designed for harsh and highly regulated environments, this new material leverages a strategic supplier relationship with Arkema, adding static disipative capabilities to Antero’s already impressive array of physical and mechanical attributes.

What are Antero 840CN03’s star qualities?

- Unmatched strength and chemical resistance

- Low outgassing properties

- Great for static sensitive applications

- Performance has been validated over several years by Stratasys

- Lighter weight alternative to metal

Best in Class Properties

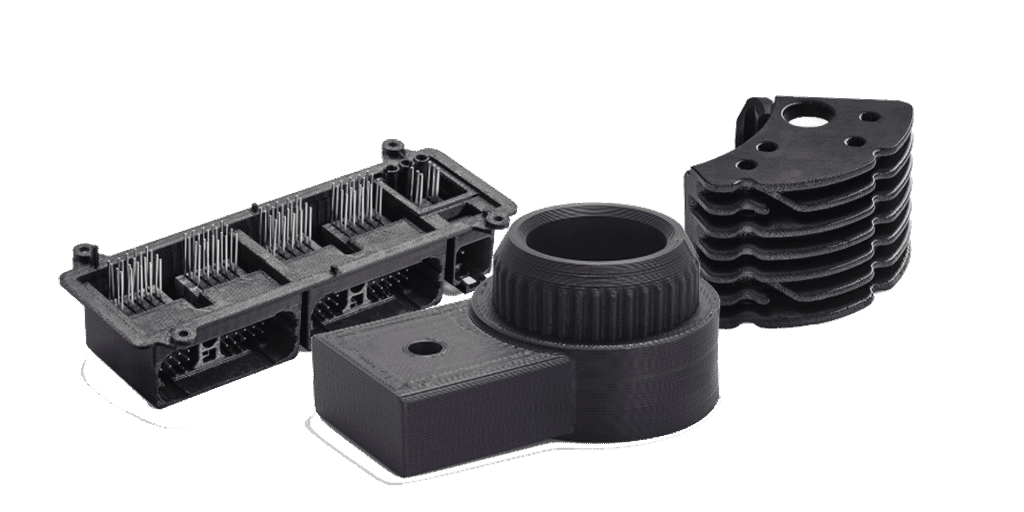

Applications

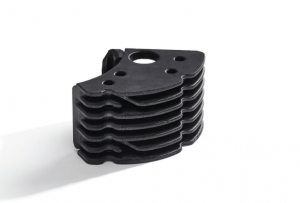

- Hatch covers

- Tools in the production of electronic components

- Functional prototypes for high-demand applications

- ESD safe jigs and fixtures for testing and assembly

- Low-volume and end-use parts for high requirements.

What printer can it be used on?

This new material can be used on the F900.

View the data sheet for Antero 840CN03

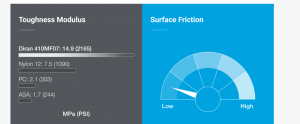

Diran 410MF07

Diran 410MF07 is a Nylon based material, delivering the strength and toughness required for manufacturing environments. However, unlike other FDM materials, Diran 410MF07 has a smooth, lubricated feel that results in very low surface friction; a valuable feature in cases where movement between parts is desired. In addition, the material’s resistance to hydrocarbon chemicals means that it’s ideal for harsh factory floor environments.

What are Diran 410MF07’s Star Qualities?

- Its slick surface offers low sliding resistance against other tools or parts

- An ideal option for tooling applications, since the thermoplastic can withstand a tough shop environment

Best in class Properties

Applications

- Tooling – Jigs, fixtures and end of arm tooling

- Prototyping – Smooth surface finishing for prototypes

- Production Parts – Low-volume production and highly customised pats

What printer can it be used on?

This new material can be used on the F370.

View the data sheet for Diran 410MF07

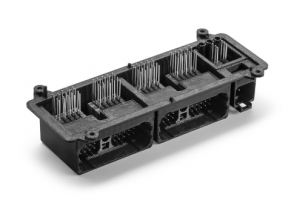

ABS – ESD7

ABS-ESD7 provides all the benefits of ABS including high impact resistance and flexural strength, however it now comes with static dissipative properties for applications where a static charge can damage products, impair their performance, or cause an explosion in a flammable environment.

What are ABS-ESD7’s Star Qualities?

- Leverage the versatility of ABS, with the reliability of FDM for lower cost and faster production

- Security of ESD protection

- Ideal for flammable environments

Best in Class Properties

Applications

- Prototyping – functional prototypes for electronic testing

- Tooling – Jigs and Fixtures for electronic component assembly

- Production Parts – Low-volume parts for industrial equipment and electronics

What printer can it be used on?

This new material can be used on the F900, Fortus 450mc, Fortus 380mc and F370.

View the data sheet for ABS-ESD7

So there you have our 3 brand new Stratasys FDM materials, now available from Tri-Tech 3D. For more information, get in touch with our team on 01782 814551 or email sales@tritech3d.co.uk.

Did you know we have a Material of the Month Newsletter? To sign up, email info@tritech3d.co.uk with the subject ‘Sign me up to material of the month!’.