Learn the top five benefits of using FDM 3D Printed tooling for sheet metal forming

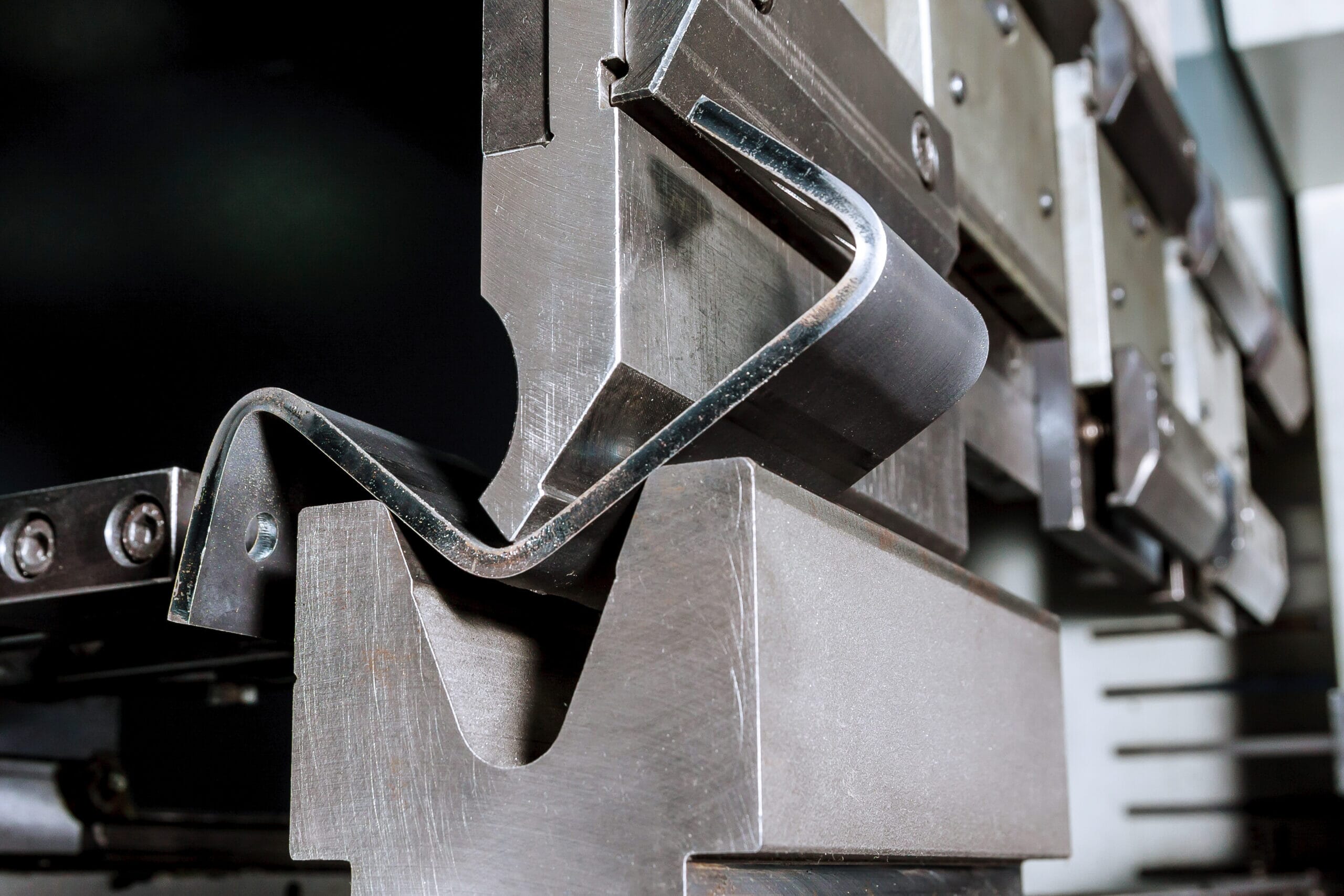

Sheet metal forming is a fundamental process in the metalworking that’s generally used for low-volume production applications. It has been employed in aerospace production lines for many years to create various airframe and engine components.

The automotive industry metal forms engine cradles, suspension components, radiator and instrument panel support beams and engine components. And the military will often produce one-off replacements for the repair of damaged vehicles and aircraft using metal forming.

Hydroforming is one of the most cost effective methods of sheet metal forming, primarily used in the automotive industry. Fluid pressure forces metal, such as aluminium, brass, alloy steel and stainless steel, directly over the die through a diaphragm. The other common method is rubber pad forming in which a ram forces an elastomeric or urethane pad to deform as it presses the metal using non-isotropic forces. You’ll often see rubber pad pressing in aerospace production for shallow parts fewer than 4 inches high.

Hydroforming and rubber pad pressing dies or form tools are traditionally CNC machined. But companies have started looking for alternative die manufacturing methods due to shortages of skilled labour, long lead times due to backlog and the high cost of raw materials. Fused Deposition Modeling (FDM) is an alternative method alleviating these challenges and helping companies move from tool design to production in as little as a week. In metal forming tests, FDM tools lasted hundreds of cycles showing little to no signs of wear.

Switching to FDM tools requires little change to current practices and procedures and offers significant benefits, including:

Reduced lead time & costs

Depending on the geometry, FDM tools can be completed in less than 24 hours. Stratasys customers saw die cost reductions of 50 to 70 percent and lead time reductions of 60 to 80 percent when compared to traditional CNC machining.

Design flexibility

Since FDM builds parts layer by layer, from the ground up, there is virtually no limit to die geometry. Organically-shaped dies can create complex metal parts for improved functionality and better part performance.

Natural porosity & lubricity

The natural porosity between layers of FDM parts lends itself well to pulling the material close to the die and reducing trapped air pockets. Also, FDM thermoplastics typically implemented for die manufacturing, like ULTEM™ 9085 resin and polycarbonate (PC), do not adhere to metals so there’s no need to lubricate metal sheet blanks.

Coordinated tool family

Since FDM builds parts from a digital CAD file, creating repeatable form tools without secondary processes or making functional updates is simple. The digital aspect also gives you the flexibility to build spare dies on demand, freeing up storage space and decreasing inventory costs.

Ergonomic factors

Thermoplastic dies are generally lighter than traditionally manufactured dies made out of metals. With the design freedom you gain from FDM, you also can design weight out of the part without sacrificing durability or integrity. This makes dies more ergonomic than traditional tooling, resulting in improved safety for tool handlers and machine operators.

Looking to take full advantage of FDM for sheet metal tooling? Get in touch with our team.