XJet 3D Printers

XJet is best-known as a pioneer of ceramic and metal additive manufacturing

What is XJet Printing?

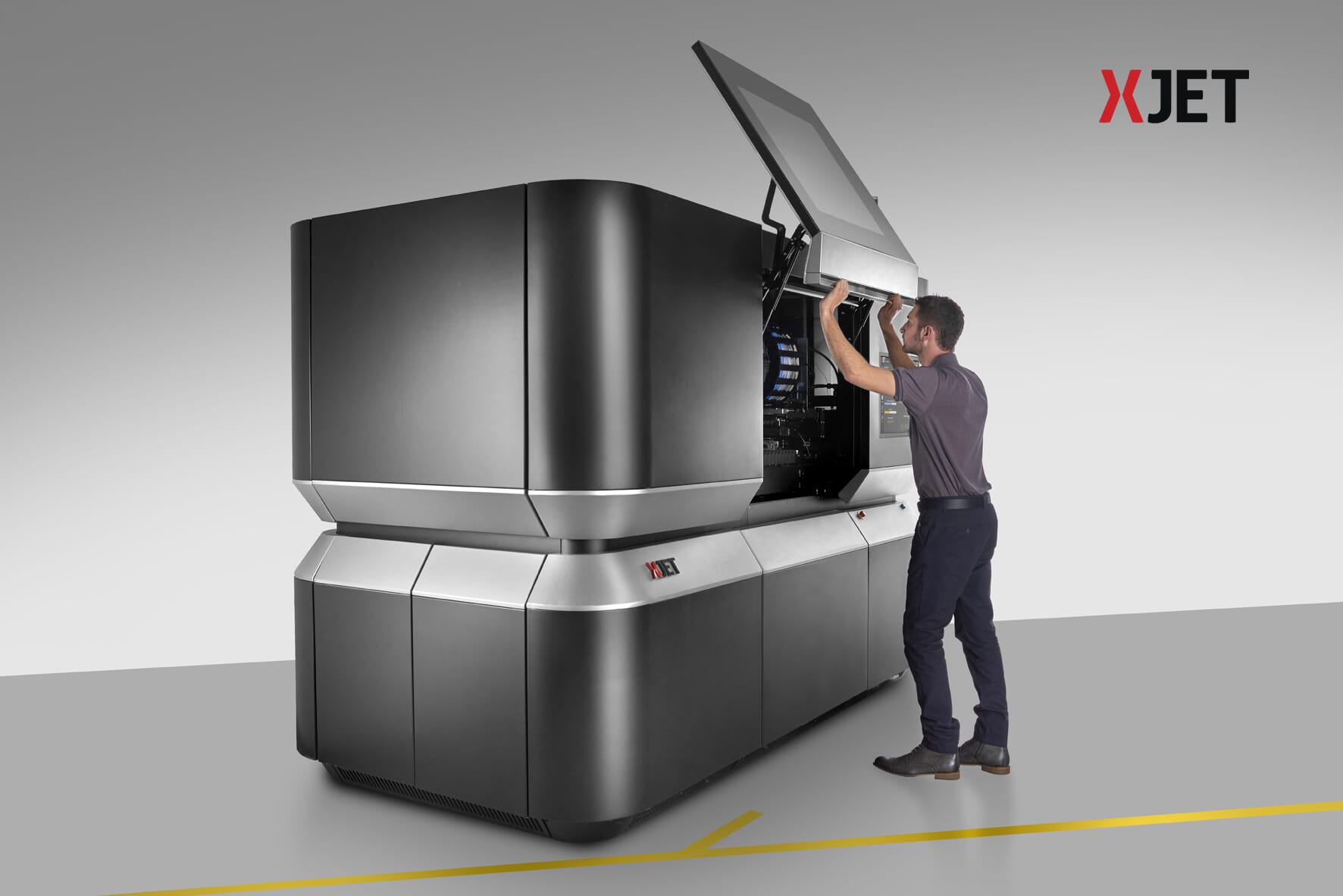

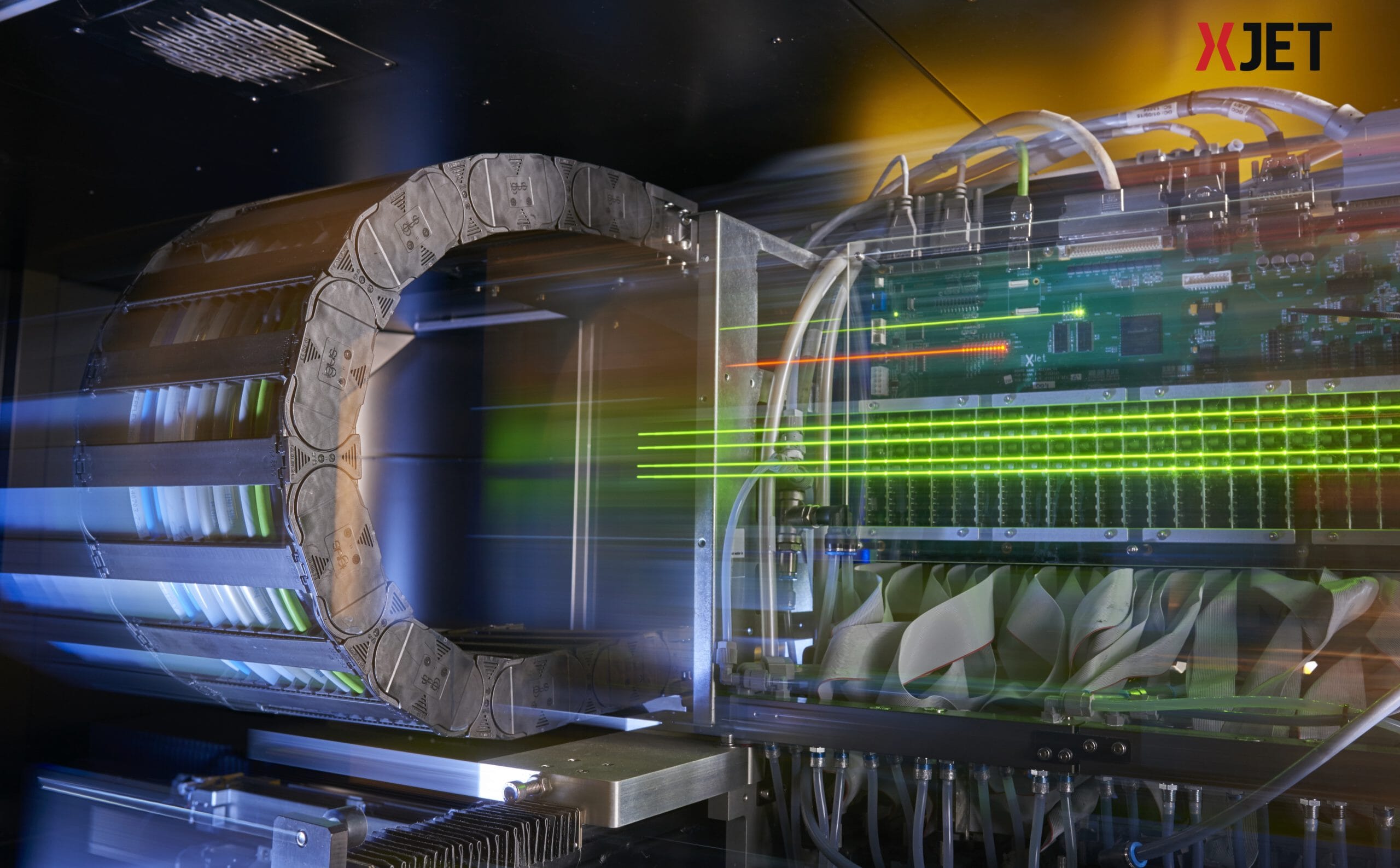

There are two XJet 3D printer models in the range – the XJet Carmel 1400M (which specialises in metal printing) and the XJet Carmel 1400C (used for ceramic additive manufacturing). In each of these models, thousands of tiny inkjet nozzles spray millions of ultra-fine liquid droplets onto the build plate – allowing an enviable level of detail, accuracy and surface finish. Soluble support materials are then dissolved from the manufactured part, leaving it ready for use (no post-processing required).

Xjet Printing Benefits

-

Exceptional qualityExpect high resolution, sector-leading precision and accuracy from XJet 3D printers, which set the modern standard for ceramic and metal additive manufacturing

-

Unique materialsCeramic and metal additive manufacturing allows the use of a wide range of compatible materials, including Zirconia, Alumina, stainless steel and many more

-

Hands-off operationXJet 3D printers operate with a bare minimum of human intervention – just set the specifications and trust this high-performance hardware to complete the print run

-

No powder handlingUnlike traditional 3D printers, with XJet Carmel series hardware there’s no need to handle loose powder – simply rely on the easy-load ink container

-

Intuitive softwareThe easy-to-use software for use with XJet 3D printers lets you sharpen your design and maximise your productivity, leading you from laptop file to final component

-

Scalable productionWith fast turnaround and simultaneous component production, XJet 3D printers speed up your time-to-market and achieve volumes that work for your bottom line

CASE STUDY

Ceramaret Expands Capabilities with XJet Technology

Ceramaret, a leading technical ceramic manufacturer based in Switzerland, has taken a significant step forward in additive manufacturing by investing in the XJet Carmel 1400C system. Known for their expertise in producing high-precision advanced ceramic parts, Ceramaret has always pushed the boundaries of what’s possible in ceramic manufacturing.

-

Can ceramics be used in additive manufacturing?

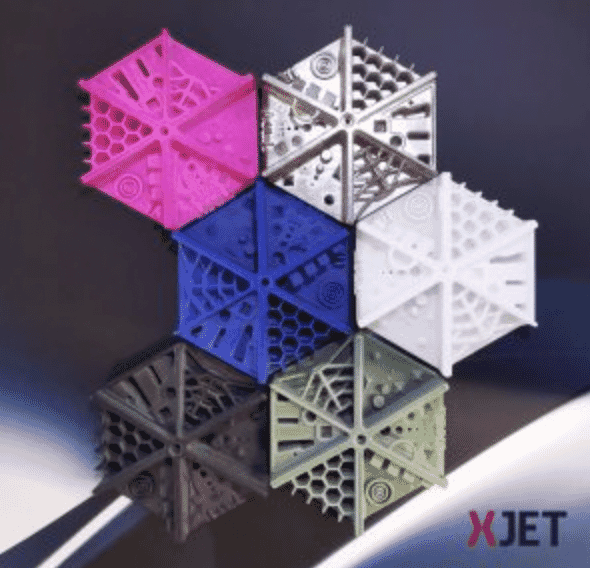

Yes. While more traditional 3D printers use ceramic powders, the XJet Carmel 1400C employs liquid ceramics which are sprayed onto the build tray to form components. The resulting parts are of the highest quality, featuring sector-leading levels of detailing, accuracy and surface finish – with no compromise to build time.

-

Which printers can print metal?

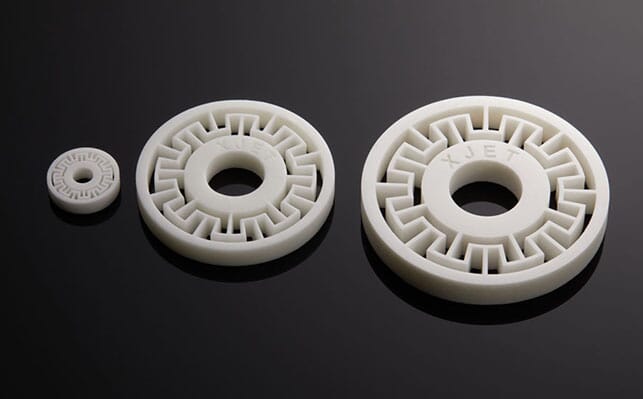

The XJet Carmel 1400M is widely viewed as the highest-performance metal additive manufacturing system, trusted across the gamut of industries who require best-in-class quality, accuracy and repeatability, not to mention the option of scalability. At Tri-Tech 3D, we’re pleased to offer this model and all associated materials and software – just ask the team for more details.

-

How does XJet 3D printing work?

Both XJet 3D printer models are underpinned by the company’s NanoParticle Jetting technology. One of the unique selling points of the process (described above) is that the component and the soluble support are printed at the same time. Once the build is complete, the support is washed away in water via the automatic SMART process.

-

What are XJet 3D printers used for?

The high-quality componentry possible with XJet 3D printers has seen this hardware used by businesses across the spectrum of global industry. Today, you’ll see ceramic additive manufacturing used for pressure sensors, earbuds and watches, while metal additive manufacturing runs the gamut from fashion accessories to surgical forceps.

-

How accurate is XJet 3D printing?

Both XJet 3D printers are highly accurate (the XJet Carmel 1400C boasts a possible layer thickness of 10 microns, while the XJet Carmel 1400M can achieve 8 microns). As such, parts with complex geometries are eminently possible with this technology. But that doesn’t come at the expense of scalability – both Carmel models feature some of the AM sector’s most generous build trays.

-

Which materials can be used in ceramic and metal additive manufacturing?

The sheer breadth of feasible materials is what attracts many users to the XJet 3D printer range. To take the XJet Carmel 1400C as an example, popular options supplied by Tri-Tech 3D include C700 Alumina (a fine ceramic material with stellar chemical and physical stability) and C808 Zirconia (a highly chemical-resistant ceramic). We also stock a huge material range for the XJet Carmel 1400M.

-

How much does a XJet 3D printer cost?

XJet Carmel 3D printers are keenly priced, while Tri-Tech 3D offers various purchase options, including flexible finance or short/long-term lease. For the most up-to-date pricing on our XJet 3D printer range, please contact our team by phone, email or enquiry form.

What are common applications for Xjet?

New to 3D

Printing or looking

for some support?

- Call: 01782 814551

- Email: info@tritech3d.co.uk