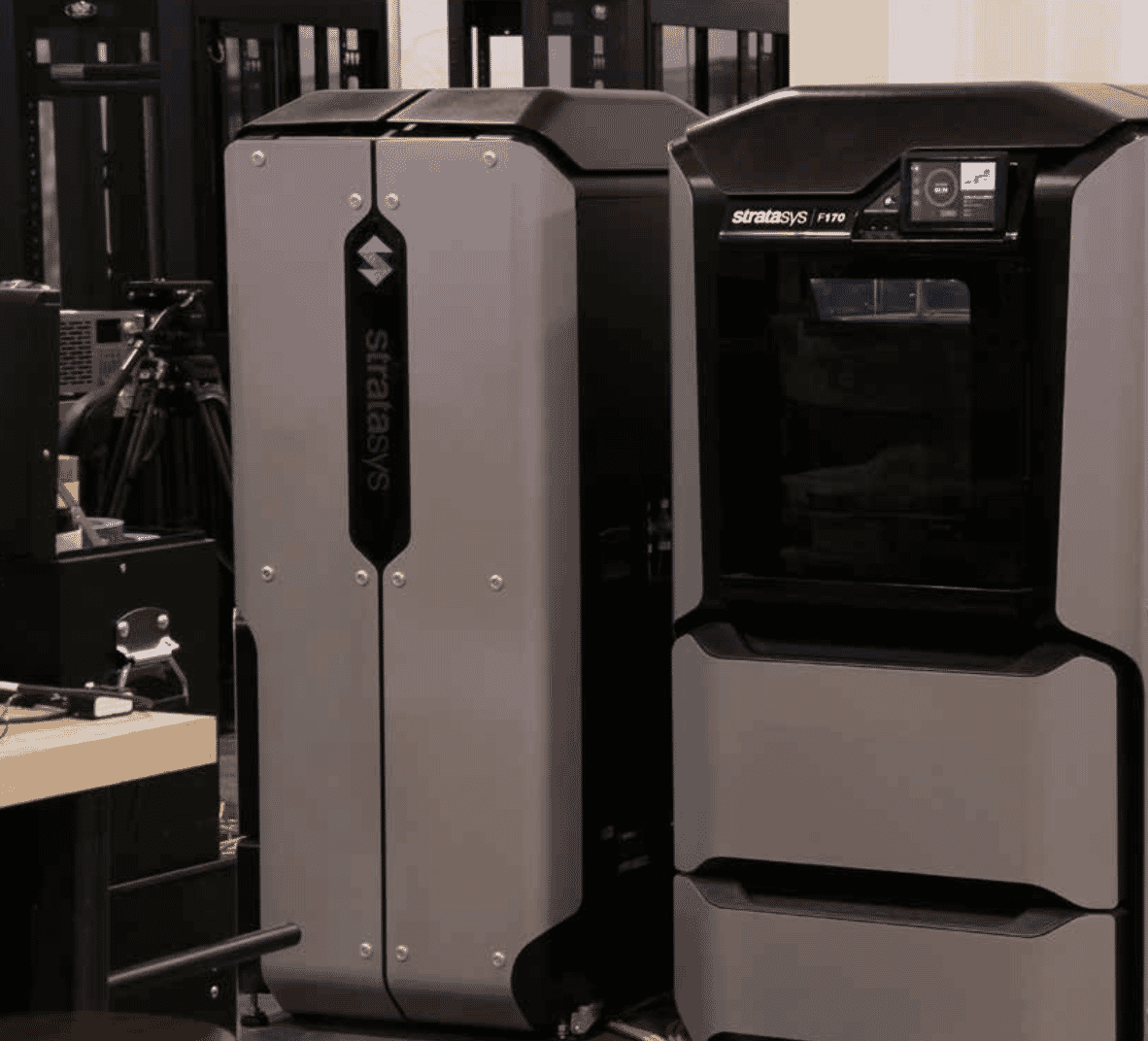

Take a deep dive into the Stratasys F123 Series printers with our Stratasys Sales Specialist Dave Moore.

The Stratasys F123 Series is a popular 3D printer with it’s highly intuitive and easy to use interface and high performance capabilities, it’s easy to see why the F123 series is one of the most predominant choosings for our customers. With applications ranging from prototypes to concept models as well as functional performance, the versatility, speed and accuracy of the F123 series makes it a winning contender when it comes to investing in 3D print technology.

Here at Tri-Tech 3D our team are passionate about providing high quality service and impartial advice to our customers when consulting on our Stratasys 3D print technology, but we’ll let you into a secret – One of our Stratasys sales specialists stands out when it comes to his expertise of the F123 series and he’s managed to gain the nickname ‘F123 series King’ amongst our team! We’ve pinned down our ‘F Series King’, Dave Moore, (and we literally mean pinned down, as he’s so busy with F123 Series projects!) to discover his F123 Series secrets…

What is the most common industry the F123 Series has been going to?

The most common placement for most of my F123 series printers has been Rapid Prototyping offices and design agencies. The ability to have an office friendly 3D printer, that is not only easy to use but aesthetically pleasing is a massive plus. It fits seamlessly into the office environment and is a real asset to the collaboration of the design and engineering teams.

What do you think the main reasons are that people love the F123 Series?

Accuracy and reliability of the machine, and the models it produces. It really lets you print everything from fast, low-cost concept models to durable assemblies and supports, you can create complex parts with no compromise on accuracy, detail and repeatability.

What’s more, you can print in a great range of materials such as PC ABS for hard wearing jigs and TPU 92A for product protection.

Do you think the ability to print in TPU has been a game changer for this Stratasys range of machines?

Yes, it’s been a massive selling point. It’s been particularly useful for customer printing product protection goods, and I’m currently in talks with a few customers who are looking to test out TPU for some seal testing.

Out of the 3 printers in the range, which is your favourite and why?

It’s got to be the 370. The ability to use Insight to control the internal build of parts is really useful for customers who are focusing on light weighting etc.

What’s your favourite feature of the F123 series?

Apart from usability and how easy it is to operate, I would say product reliability. Not only do our customers get fantastic results from their prints, but they know they can leave the printer printing over night for example without worrying it will stop.

For more information on the F Series range of printers, get in touch with our sales team. Interested in learning more about digital design software for concept development? Head on over to our sister company Cadspec.