PolyJet and FDM technology create new era for toy company

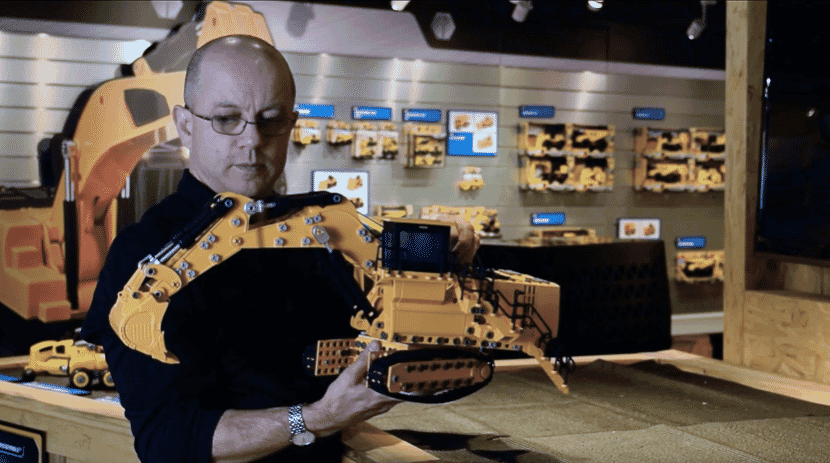

With a launch of more than 200 new toys a year aimed at preschoolers, young children and hobbyists, designers at Toy State International Ltd. (Toy State), have a real need for speed in their design to prototype timeline. Streamlined design and quick production turnaround schedules are critical for the design team who generate new ideas, sketch concepts and create models of early designs and functional prototypes in real plastics for performance testing.

Already a user of a Stratasys PolyJet 3D Printer, Toy State continued to strive to reduce modeling labour, cut costs and launch new products in a more timely fashion.

Guy Nickless – R&D Director at Toy State commented:

We used PolyJet mainly to create tools or some concept models, but for functional prototypes we still relied on sub-contractors. Consequently, the process was not optimised; it was lengthy and more expensive.

With highly intricate designs in the works, Toy State sought a tool that could create precise prototypes in materials similar to their end-use parts, while maintaining the strength to withstand functional tests. The answer? FDM and the Stratasys F370 3D printer.

A tool for every project

The release of the Stratasys F370 was just the right solution for Toy State.

Toy State, an industry leader in manufacturing lights-and-sound and radio- controlled toy vehicles, wanted to create a drone strong and stable enough to withstand wind in mid-air while still being light enough to fly, even after embedding electronic components. The team needed to produce small parts that snapped together while facilitating the ideal arrangement of motors, battery cases, covers and other parts. With the Stratasys F370, Toy State was able to 3D print prototypes that fit all the desired requirements, including the ability to print with ABS or PC-ABS plastics, which possess similar production-grade material properties as their end products.

Nickless commented:

We were all surprised at how easy and intuitive the Stratasys F370 is to use. All we need to do is prepare the CAD file, import it to the GrabCAD Print software and sync it to the printer. With just a few presses of different buttons, the drone gets prototyped in PC-ABS.

With the Stratasys F370 incorporated into the design and verification process, the team is now empowered to be more responsive to projects in a collaborative environment.

Connecting team members with GrabCAD Print

Plus, with cloud-connected GrabCAD Print, the team can monitor print status, check material consumption and manage print jobs via their computers or smart phones. This makes it easier to fit 3D printing into an engineer’s daily work as well as the R&D team’s design verification schedules. Adding the Stratasys F370 into their workspace helped Toy State move prototyping in-house for a more streamlined design verification process and the team plans to expand their 3D capabilities by training modelers to be fluent in 3D design.

To find out more about the Stratasys F370 or to get your very own sample part, get in touch.