FDM Direct Digital Manufacturing for Sheppard Air Force Base

Based at Sheppard Air Force Base, Wichita Falls, Texas, the Trainer Development Flight (TDF) is a facility that designs, develops, and manufactures trainers and training aids for the Air Force and all branches of the Department of Defense (DoD) as required. These items are used in numerous training environments, including avionics, weapons and fuel systems, medical readiness, HVAC, and telecommunications systems.

The trainers and training aids may be either original products or replicas of existing ones, depending on the training need. Some devices are not required to be working units, so it usually isn’t cost-efficient to purchase the actual item. For most training applications, it’s more economical to train students on replicas, instead of the often extremely expensive equipment.

The TDF uses direct digital manufacturing to fabricate a wide majority of its training products. To do so, it employs four FDM additive fabrication machines in a centralized location with AFSO 21 (Lean) processes incorporated into the overall process.

Real Challenge

Before adding direct digital manufacturing to its processes, the TDF used conventional manufacturing methods to make its products. Conventional manufacturing typically requires longer lead times because there is often multiple steps, such as machining, lathe work, welding, sheet metal bending and cutting. A similar difficulty occurs when producing tooling to mold a part.

“Because most of our projects are either one-of-a-kind or very low volume, conventional methods become very expensive,” says Mitchell Weatherly, Chief of the TDF. “Only about 10 percent of our work is for prototyping, and 90 percent is production.”

Real Solution

Before settling on FDM, the TDF considered “a multitude” of the other additive processes, says Weatherly. “With FDM, the investment is up front, not ongoing,” he says. “The parts are durable, and they have the high level of detail we require. In addition, the process is environmentally safe and 100% ‘green’ with zero waste.”

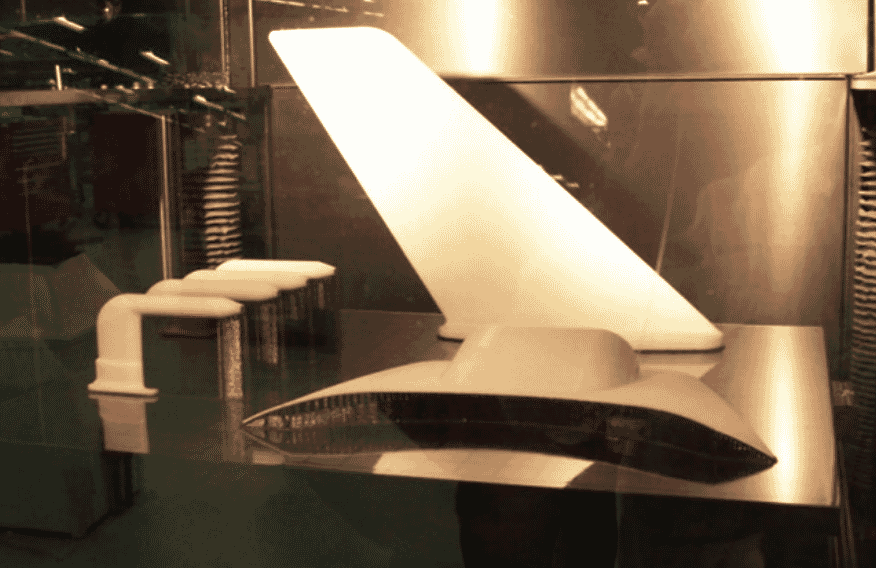

The TDF is responsible for designing and manufacturing an exact replica of an unmanned aerial vehicle (UAV) or “drone” for training repair technicians. It has built a variety of internal and external components using its FDM machines. The components included most of the body components as well as several cowlings, propellers, and antennas. They also purchased a number of real UAV components from the OEM.

Real Benefits

Just for producing the UAV’s large antenna alone, using the FDM machines did the job in about one-tenth the time it would normally have taken with conventional methods, and it delivered an ROI of over $12,000. The savings go beyond time, though. For the antenna, it would have taken an outsourced machine shop up to 20 days to produce the part, where it took only two days using FDM — but only 15 to 20 minutes of labor. For the entire UAV project there was a total time saved of more than 3 years in some areas. This project, along with other trainer savings has been very impressive with an $800,000 cost avoidance over the last four years.