Kinetic Vision uses the J55 Prime to improve product development

With over 35,000 SKUs in an average big-box retailer, there is tremendous pressure to develop product packaging that breaks through the clutter to capture more sales.

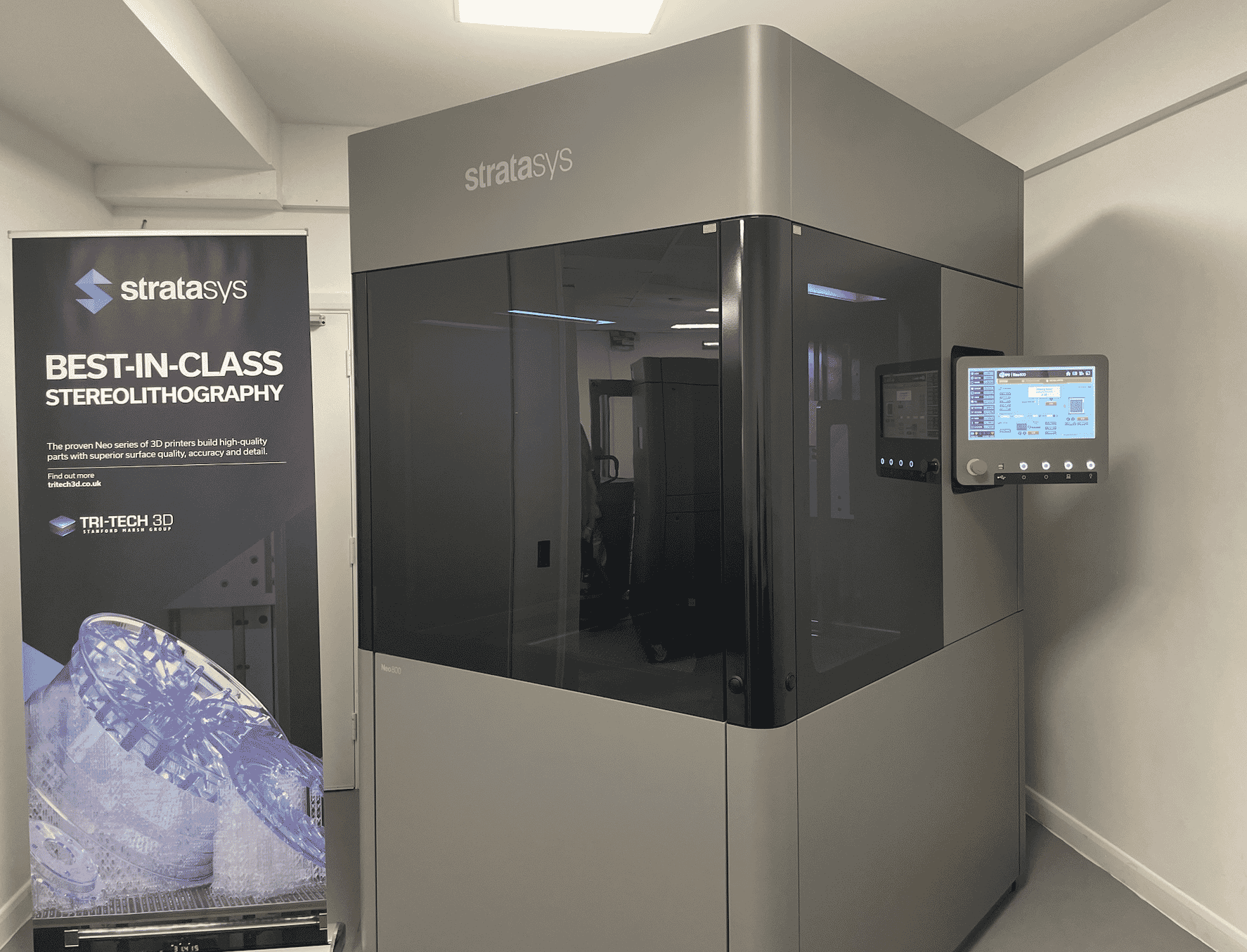

Kinetic Vision, a Cincinnati-based design and technology company, has been creating innovative packaging for Fortune 500 companies for over 30 years and shares how they have recently powered up their packaging development process utilizing the new Stratasys J55™ Prime 3D printer.

For Kinetic Vision, packaging development is a holistic process that integrates multiple technologies. The company not only does the industrial design, but also engineers the products, and then performs modeling and simulation and even computed tomography scanning of the product.

Tony Guard further commented…

Our company is very different from others since we are constantly developing and integrating advanced technologies to accelerate innovation. A good example is that we can now design in virtual reality and never touch a sketchpad. This allows us to move instantly to 3D and to create prototypes faster

Advanced Technology Changes Packaging Development

A major pain point for Kinetic Vision was getting fast and accurate models of their designs. Prior to using 3D printing for product packaging, Kinetic Vision outsourced modeling projects. While many model shops were highly skilled, there was often a struggle when it came to specific patterns or details, especially if the model consisted of clear materials. Simple design models were easy, but to create highly accurate, complex designs was difficult and very time-consuming.

The team at Kinetic Vision unwrapped and installed the J55 inside of an hour – and created their first print in the next few hours. The plug-and-play versatility of the J55 and its small footprint made it ideal for the Innovation + Industrial Design group.

Guard commented:

Not only was the J55 easy to set up, we were amazed at how quickly we could move from design to print. When the first print came out, with the full array of colors and textures, we were simply blown away

From Zero to Final Product in Two Weeks

To see the real power of the Stratasys J55, the Kinetic Vision team embarked on a two-week sprint to concept, design, and produce a product for a new beverage brand. The goal was to understand how the J55 could intersect and accelerate product packaging design.

Higher Consumer Research Efficacy

The Kinetic Vision design process is anchored in consumer research – ensuring that critical steps in the design process are vetted and validated by people touching and handling product prototypes. The better the product prototype, the better the accuracy of the consumer research. The Stratasys J55 and its high-fidelity print capability has dramatically improved the quality of the research for Kinetic Vision.

The company’s packaging development process now includes the J55 at critical intersection points in the process. Summarizing his team’s experience with the J55, Guard added…

There is no doubt that the Stratasys J55 has helped us rapidly accelerate our design process

For further information on the Stratasys J55 Prime or PolyJet technology, please get in touch with our team.