Autodesk’s Technology Centre in Birmingham takes delivery of revolutionary laser powder bed fusion 3D printing system

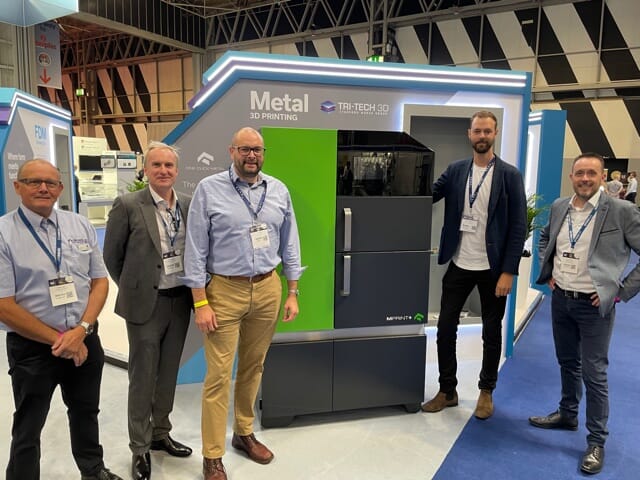

Stoke-on-Trent, September 29th 2021 — Tri-Tech 3D, part of the Stanford Marsh Group and one of the UK’s most established providers of 3D printers, solutions and training, are proud to supply the first One Click Metal MPRINT+ 3D printing system (part of the BOLD series) to a key client this month. The MPRINT+ will be a vital asset for Autodesk’s Technology Centre in Birmingham: a pioneering research, development and manufacturing facility owned by the US software corporation.

Representing the next generation of One Click Metal’s (OCM) acclaimed MPRINT 3D printer, the new MPRINT+ is an accessibility-focused metal system designed by the German manufacturer for industrial prototyping and low-volume series production applications. It promises greater precision and higher output, with uprated features over its predecessor that include a new 200W fiber laser and galvo scanner.

It is the accessibility to metal powder bed that is most interesting about the OCM solution.

says Nick Hill, Operations Manager at Autodesk Birmingham.

Much like Autodesk’s Fusion 360, OCM is democratising access to technology that would previously have only been available to OEM and 1st tier manufactures. Of course, OCM’s solutions being designed in Fusion 360 is a nice bonus too. The cartridge-based powder system is something unique that significantly reduces the exposure of users to loose powder and makes the system a lot safer to use. I also like that compared to other competitive systems, there is no need for post sintering operations (material-dependent), which speeds up the time to produce components.

Just one of Tri-Tech 3D’s comprehensive range of 3D printers – which also includes Stratasys FDM, SAF, P3, Polyjet and Stereolithography – the MPRINT+ system will support the Autodesk Technology Centre’s work in fields from automotive to aerospace, while facilitating research projects, training and production. Hill commented:

We plan to use the MPRINT+ to support the continued development and testing of metal AM in our Fusion 360 platform and developing additive to subtractive workflows. We will also be working with partners to spread the word and help customers understand how they too can adopt this technology.

With Tri-Tech 3D’s sister company, Cadspec, also providing Autodesk software and accredited CAD/CAM training, this latest development confirms the Stanford Marsh Group as a one-stop provider. Colin Cater, Sales Manager at Tri-Tech 3D commented –

To have Autodesk as our first UK customer further cements the relationship between Tri-Tech 3D and Cadspec as a single source supplier for CAD/CAM and 3D Printing. The OCM solution is ideally suited to ease of use, safe operation and ultimately fine accurate and detailed parts which we believe is an Autodesk primary benefit when entering the world of metal AM.

To learn more about the One Click Metal MPRINT+ or Autodesk’s Technology Centre in Birmingham, visit https://www.tritech3d.co.uk/, https://oneclickmetal.com/en/ and https://www.autodesk.com/technology-centers/birmingham-uk

About Tri-Tech 3D

A Stanford Marsh Group company, Tri-Tech 3D is the UK’s most trusted suppliers of 3D printers, technology, solutions & training. For more information, visit https://www.tritech3d.co.uk/

Press Contacts:

Tri-Tech: Catherine Aspinall | Marketing Manager Catherine.aspinall@stanfordmarsh.co.uk

One Click Metal: Miriam Stiller | Marketing & Communications Manager Miriam.stiller@oneclickmetal.com