3D Printer maintenance explained

The betterment of production processes has always been the primary selling point of 3D printing, as many salespeople have likely explained to you on countless occasions. But once you have a printer within your walls it would be a shame to see any benefits slowly (or suddenly) disappear? If printers aren’t maintained, then their value to your business shrinks.

Here’s our breakdown of why every printer owner should consider Tri-Tech 3D’s printer maintenance service and some handy tips on how you can get the most from every single print!

Business benefits

It goes without saying that any printer you have, regardless of technology or manufacturer, needs maintaining. It’s more than a mere possibility that the technology will perform exponentially better on a well-maintained printer than one severely neglected.

Now, while physical print speed is not something that can necessarily be improved through machine maintenance, output can certainly be affected. Downtime is every manufacturers nightmare – despite the restful connotations of the word in any other scenario. The reduction of downtime is particularly important in dynamic industries such as design or engineering, where printers are required to be in a state to react to design changes and for fast turnaround of prototypes or end parts. If an assembly can’t progress without a specific part that can’t be printed, there will clearly be consequences. When downtime can cost some high-performing automotive companies around £20,000 a minute, the monetary figure placed on downtime is worth knowing about even for businesses on a much smaller scale. When downtime loses money in the long run, simple maintenance pays dividends often multiple times over.

Print quality – what needs maintaining?

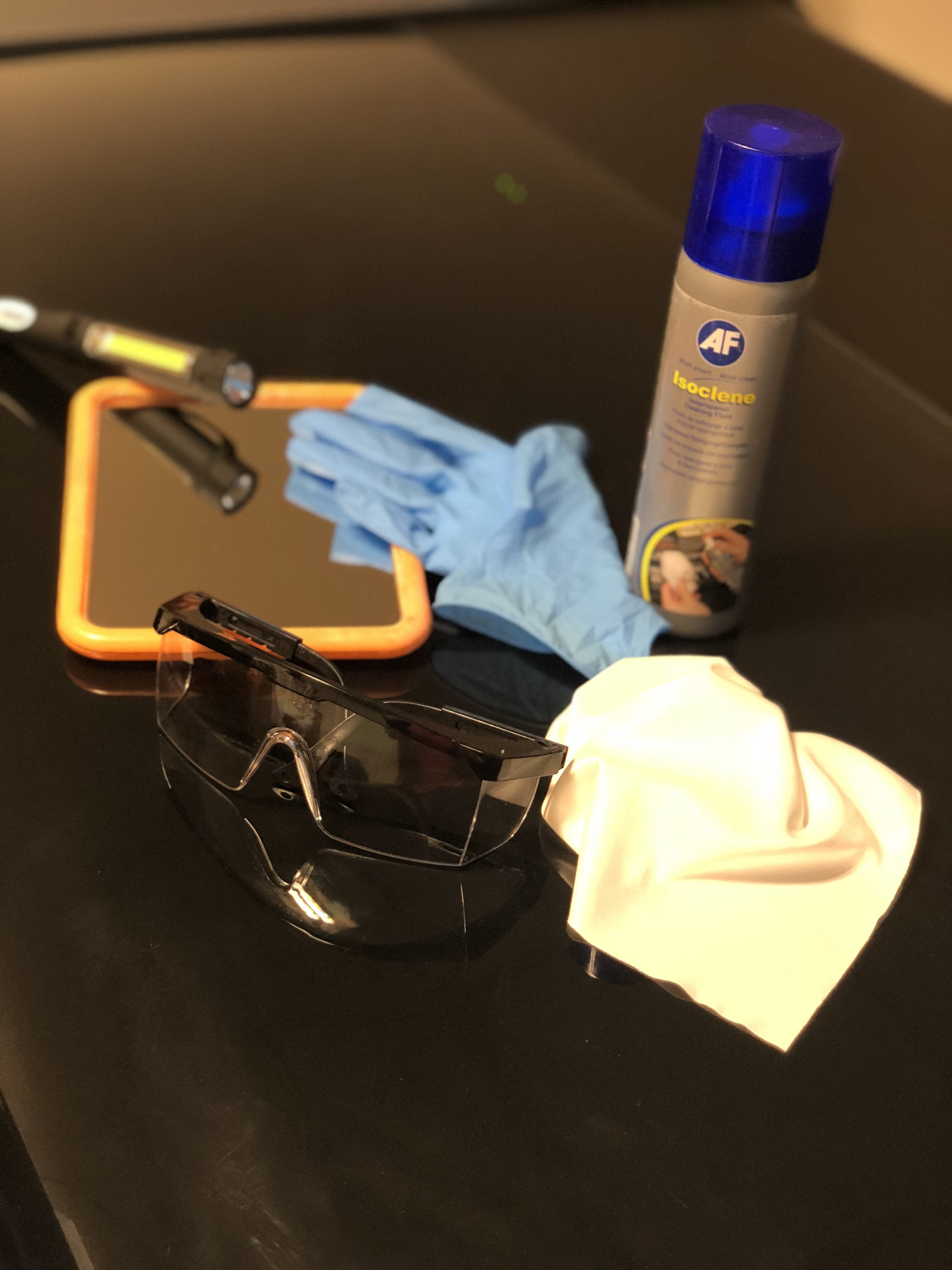

A high-quality print can be defined through a cross-section of multiple factors being optimised for the specific print. This primarily includes layer thickness, material choice, temperature of the chamber, and retraction. Many different parts of the printer need upkeep in order for each of these factors to produce an ideal product. Thankfully, many of the regular maintenance tasks can be performed easily with a little knowledge and will ensure print accuracy.

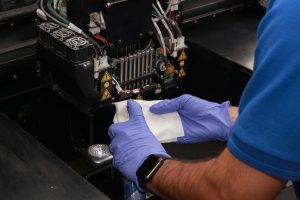

For example, cleaning extrusion tips when they become clogged; this can happen at varied times depending on material usage and tip size, but as the user this message is displayed on the UI of all FDM machines. It sounded potentially complex, but the printer takes care of the difficult part. Calibration is equally critical and a fundamental part of regular maintenance. Ideally, it’s performed after every print, but a slightly longer wait time would suffice.

The print quality is affected in largely the same way for both FDM and PolyJet, you can’t expect peak efficiency and reduced downtime from a printer that’s left alone for weeks. Are your tips blocked? Is your purge shaft clear? Is your printer crying out for some TLC? We hope not, but there are services offered if you should need them.

Alex Bordino (3D Print Academy Trainer) on why he’d recommend Tri-Tech 3D printer maintenance…

I would highly recommend printer maintenance service to customers as it will ensure that your printer is working at the optimum all of the time. As an engineer or designer, you don’t want to spend time managing machinery: you want to spend time solving problems and generating revenue. A printer maintenance service will facilitate that and subsequently prolong the life span of your printer.

Sadly, we just detailed examples of the “easy” tweaks you can make for your printers. But support is available for those incidents when the printer gives up the ghost, for both FDM and PolyJet systems. There’s a lot to think about when taking proper care of your machine! If you want to find out more about the support contracts that Tri-Tech 3D can offer to keep your printer in top condition, contact us here or to book on to an academy course where we show you how to effectively keep your printer in ‘tip-top’ condition, contact our Academy team here.

T: 01782 814551