Industrial additive manufacturing materials developer aims for further solutions to meet demanding applications across key sectors such as rail and oil & gas

France-based industrial additive manufacturing materials developer Kimya, an ARMOR Group company, has reinforced its collaboration with Stratasys with the purchase of two FDM® technology-based Fortus® 450mc 3D printers. The purchase follows the recent announcement that Kimya is providing two high-performance industrial AM materials for Stratasys customers.

Kimya’s ongoing partnership with Stratasys will benefit customers in two ways. First, Kimya has established a continually expanding materials development programme that will offer a greater choice of advanced high-performance options to FDM printer customers. Second, Kimya is widening its service offering in France via the production-level Fortus 450mc platform, enabling it to provide functional final 3D printed parts for demanding AM applications.

3D production capability via the Kimya Factory

Extending its proposition beyond that of advanced materials development, the ‘Kimya Factory’ will spearhead a newly created production arm to meet customers’ exacting 3D printed parts needs across key industrial sectors such as railway and oil & gas.

We have been working closely with Stratasys for several years and steadfastly believe that when it comes to operating industrial-level systems to develop and test materials and their associated application scenarios, the company’s Fortus 3D printers are the best out there.

Pierre-Antoine Pluvinage, Business Director, Kimya.

According to Pierre-Antoine Pluvinage, with its flame-resistant properties, Kimya PC-FR material is a great fit for both passenger and commercial rail applications, with applications ranging from small parts such as seat components to replacement parts and beyond.

Pierre-Antoine Pluvinage continues…

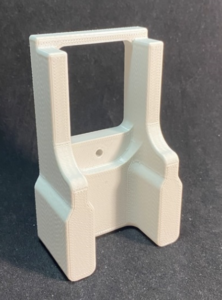

On behalf of manufacturers and OEMs within the railway sector, we are already looking at which parts can be produced for specific applications, a good example being ventilation grids for rail carriages. Working with Kimya PC-FR material on certain 3D printers would have been complicated, but we never had a problem with the Fortus. Similarly, in Kimya Kepstan® PEKK-SC, we have developed a highly technical material to surpass expectations and perform in the harshest of industry environments, among them end-use oil & gas applications like back-up rings. This is an increasingly important sector for which we continue to explore additional materials that meet particular needs.

With availability expected before the end of this year in EMEA and developed in conjunction with Stratasys, the Validated flame-retardant Kimya PC-FR polycarbonate material meets the EN45545 standard and the R1-HL2 fire hazard scale of the European railway industry.

Also available at the same time, the Stratasys Validated Kimya Kepstan® PEKK-SC is a semi-crystalline PEKK thermoplastic polymer based on Kepstan® by Arkema. The high-performance material boasts excellent mechanical properties in addition to its resistance to elevated temperatures, abrasion, and chemicals including acids and hydrocarbons such as fuel and lubricants. Kimya PEKK-SC also complies with RoHS and REACH standards, railway fire and smoke standard EN45545, aerospace FAR 25.853 flammability standard, and is flame retardant to UL94 V0.

Moving forward, Kimya plans to work closely with Stratasys to develop additional production-grade filaments for a variety of industrial sectors.