3D printing thermoplastic materials offers the strength of metal with a host of advantages...

Perhaps the biggest misconception in modern manufacturing is that, for the strongest parts and componentry, only metal will do. That might have been true a half-century ago. But in 2025, 3D printing materials have changed the playing field for good, and while metal undoubtedly still has a vital role to play, today you’ll be amazed by the high performance of the latest revolutionary thermoplastics.

Read on to learn why so many of our clients have found thermoplastics to be a viable alternative to metals – and discover some of the types of thermoplastics available from Tri-Tech 3D here.

What is a thermoplastic?

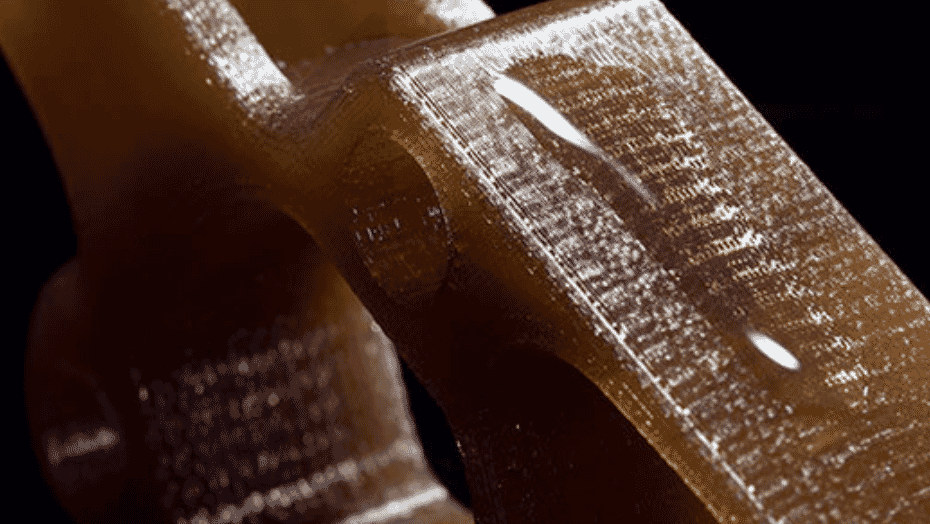

First off, a quick explainer. Fundamentally, a thermoplastic is a plastic polymer material whose key property is that it becomes soft and pliable when heated, then hardens upon cooling, without any change to its properties. Of course, that makes thermoplastics ideal for 3D printing – and that’s just the start.

The roots of thermoplastics can be traced back to the 19th century, but they’ve evolved rapidly in the AM age and you’ll now find a wide range of materials (including ABS, Polycarbonate, Nylon and many specialist blends) whose high strength and specialist properties make them ideal for almost any application.

That’s why you’ll find modern thermoplastics employed everywhere from fluoroscopy-friendly surgical instruments to weight-cutting commercial aircraft – and why they’re increasingly seen as a genuine alternative to metal.

Why are thermoplastics a good alternative to metal?

Make no mistake: metals have always been known for their strength, and that hasn’t changed. But modern thermoplastics are often just as strong, hence their use for end-use parts in demanding sectors like automotive and aerospace.

When assessing whether a thermoplastic could be a good substitute for metal, it’s worth weighing up what ‘type’ of strength your application demands.

- For tensile strength (resistance to being pulled apart), consider Nylon, PET or Polycarbonate.

- For impact strength (resistance to a sudden blow), consider ABS or Polycarbonate.

- For flexural strength (resistance to being bent or twisted), consider PVC or Polypropylene.

- For compressive strength (resistance to being crushed), consider PEEK.

Of course, this is just a general overview: for a detailed guide of our thermoplastics and how their strength measures up against metals, read each product’s data sheet or ask the Tri-Tech 3D team for guidance.

What other advantages do thermoplastics have over metals?

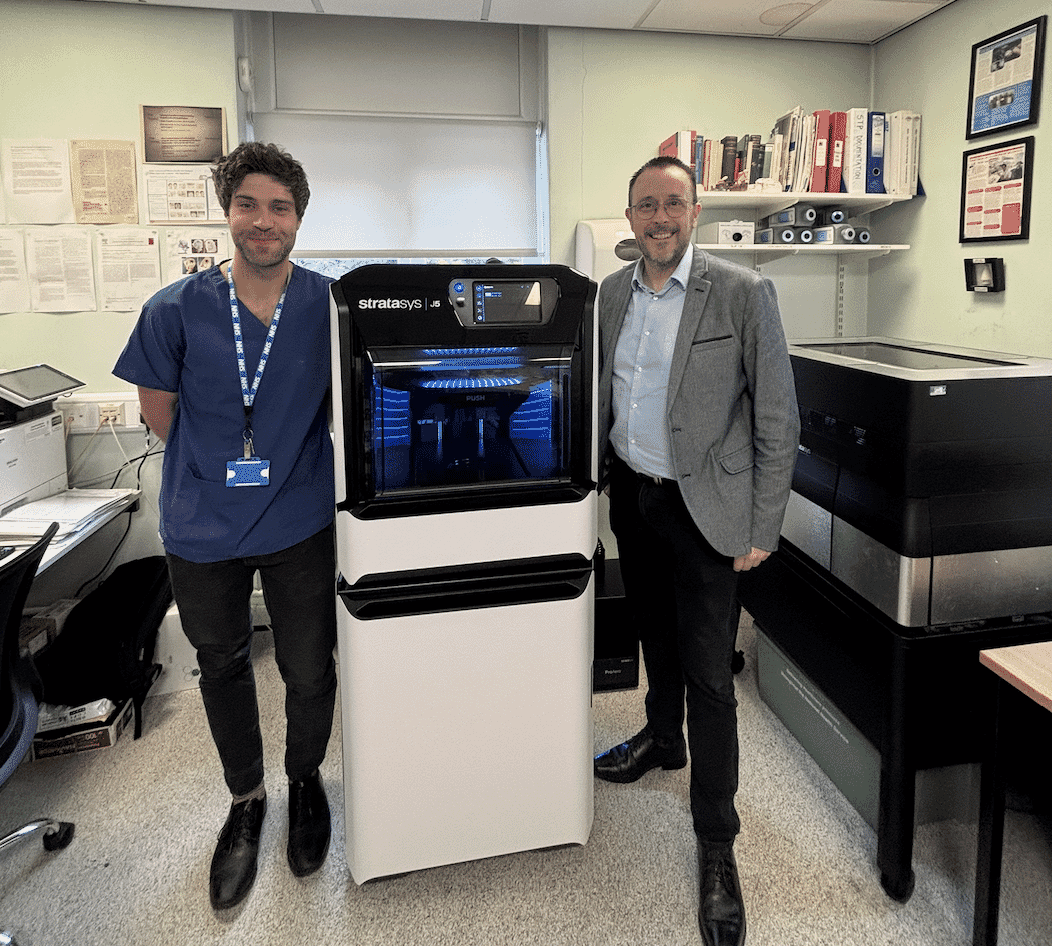

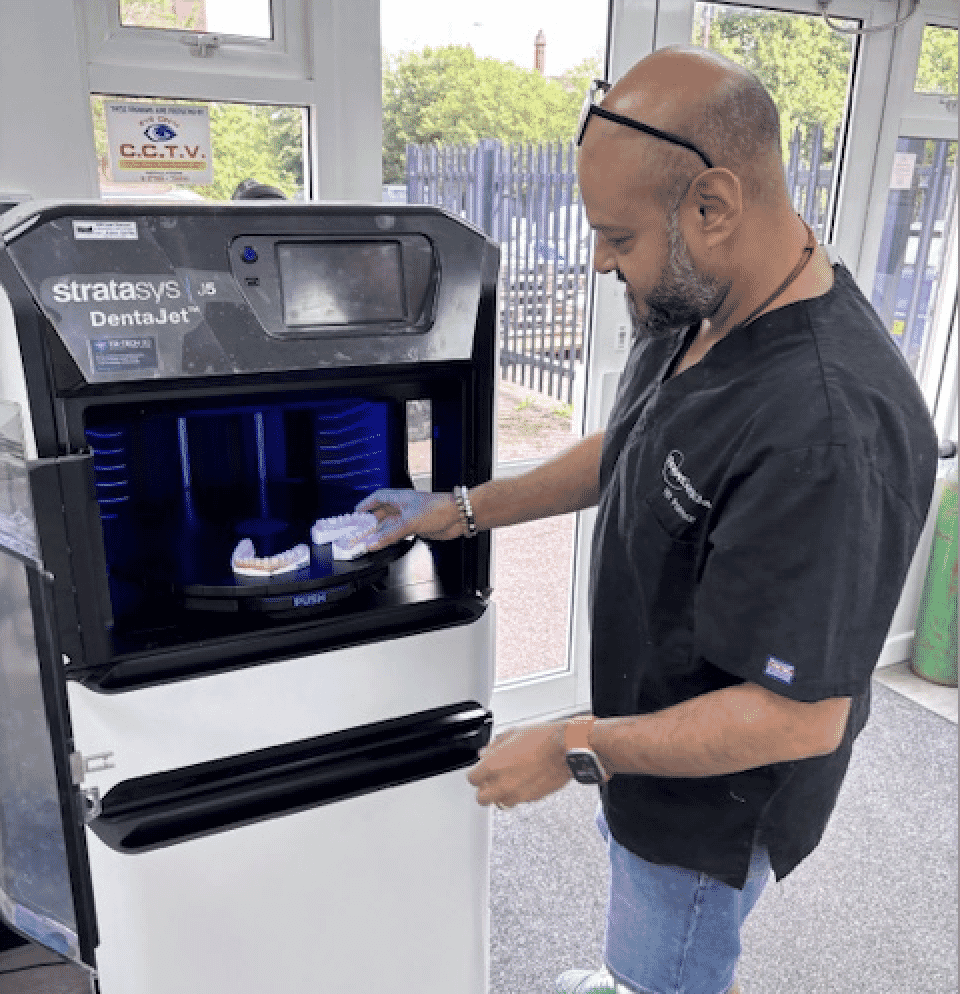

Modern thermoplastics rival metals for strength – but that’s not the only argument for choosing them. With world-leading AM pioneers like Stratasys releasing revolutionary new thermoplastics all the time, it’s now possible to find a material whose properties are practically tailor-made for your application.

Here are just some of the potential benefits of thermoplastics:

- Lightweight. This reduces transport costs, boosts fuel efficiency and allows (for instance) aerospace designs which wouldn’t be possible with heavier metals.

- Corrosion and chemical-resistant. As well as being FST rated, many thermoplastics won’t rust or corrode, even in environments where water or chemicals are present.

- Design flexibility. It’s relatively easy to mould thermoplastics into ambitious forms with no need for secondary machining.

- Cost-effective. Thermoplastics and the processes involved in treating them are typically less expensive than metals and metalwork.

- Sustainable. The chemical properties of thermoplastics means these materials can be melted down and reused many times.

- Non-conductive. Due to their electrical-insulating properties, thermoplastics can be safely used in circuits and electrical housings.

- No welding required. Removing this onerous step allows for faster production cycles relative to metalwork.

What 3D printing thermoplastics are available from Tri-Tech 3D?

At Tri-Tech 3D, our goal is to guide our clients to the most suitable materials for the job at hand. For some applications, that might be metal. But we’re always ready to talk you through our comprehensive range of thermoplastics and assess which product will best meet your needs.

From tough, impact-resistant Nylon 6 to ABS ESD7 with its static-dissipative qualities, you’ll find our full range of thermoplastics here.