How Altrad Belle Accelerated Innovation and Cut Development Time with Stratasys 3D Printing

Altrad Belle is a UK-based manufacturing company specialising in a wide range of light construction equipment. Its products are primarily sold to major rental companies across the UK and Europe. In 2008, Belle became part of the Altrad Group – a global organisation comprising over 170 companies.

The group’s expertise spans light construction equipment, scaffolding, and maintenance services, particularly within the oil and gas industry.

The Challenge

While the COVID-19 pandemic brought significant challenges – including a reduced design team and surging product demand – the need for change at Altrad Belle was already clear. The Design Development team faced increasing pressure to deliver faster, more flexible solutions to engineering challenges using fewer resources.

Rather than viewing COVID-19 as the driver of change, the team recognised a deeper, ongoing need to transform its approach to design and prototyping. A key opportunity emerged: embracing 3D printing to streamline workflows and accelerate product development. This led to the introduction of a Stratasys F370 3D printer.

The Solution

Altrad Belle didn’t just want a 3D printer – it wanted a full 3D printing solution. That’s where Tri-Tech 3D and Stratasys came in. Their professionalism and consultative approach stood out immediately. Through Tri-Tech’s 3D Print Bureau, Belle had the opportunity to trial Stratasys’ capabilities before making an investment.

Robert Pitts, Sales Manager at Tri-Tech 3D:

After visiting Altrad Belle and walking the factory floor to evaluate their requirements it became apparent they would require a versatile technology that could be used for a wide range of applications. We landed on the F370 due to being user friendly so that the whole design office could access and use it. Due to the flexibility of different materials it meant it could be used for prototyping, tooling and end-use functional parts that could be fitted on their products. This allowed them to go from prototyping to functional testing and production all on the one system.

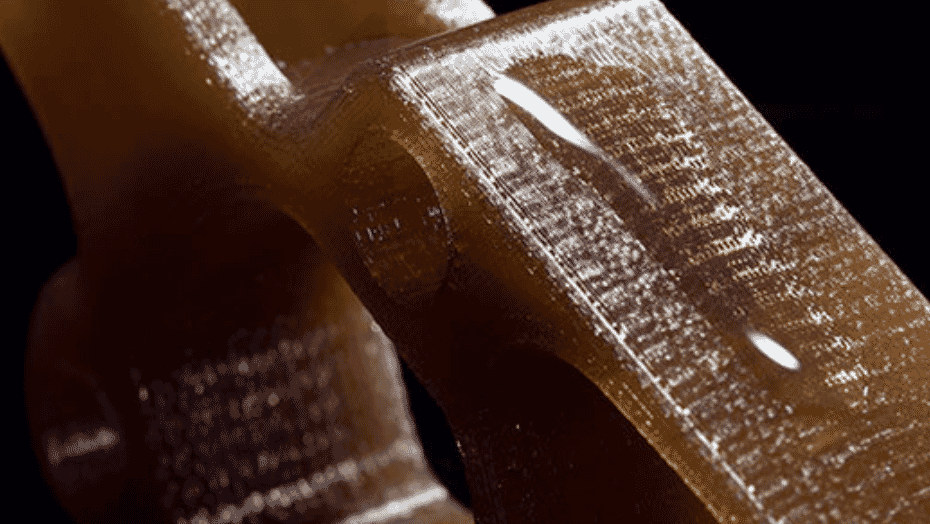

The partnership provided access to a broad range of advanced materials, enabling the Belle team to print functional, real-world parts – not just visual models or prototypes. From the outset, the goal was clear: to produce usable components directly from the printer, speeding up development without sacrificing quality.

Results

Since adopting the Stratasys F370 solution, Altrad Belle’s Design team has unlocked a new level of creativity and agility. With the ability to print complex plastic components without costly tooling, the team has been able to:

-

Design more elaborate parts for low- to mid-volume production.

-

Rapidly prototype ideas without waiting on internal manufacturing.

-

Produce fully functional prototypes for live demonstrations and customer feedback.

-

Reduce disruption to production lines by removing the need for one-off sample parts.

This transformation has not only streamlined internal processes but also shortened the time to market for new machinery and product innovations, delivering a clear competitive advantage.

Introducing 3D printing has completely changed how we work. We can now trial design ideas, create fully operational prototypes, and make quick changes without slowing down production. It’s helped us become faster, more efficient, and more innovative.

Adam Thompson, Senior Design Engineer, Altrad Belle