Here’s what you need to know about the growing role of polymers in aerospace…

In the fast-paced world of aerospace, you’re constantly under pressure to deliver aircraft that’s lighter, safer, and more efficient. Every design choice matters, and the materials you select can make or break your aircraft’s performance. Aluminium and titanium have long been the mainstays, but the industry is evolving fast, and more engineers are now turning to advanced polymers to meet their challenges.

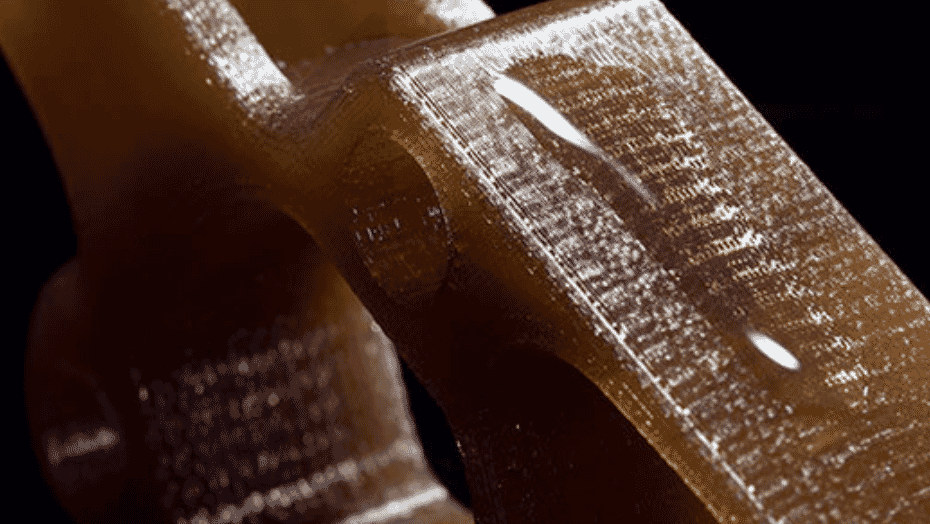

And right at the centre of this shift is PEEK (Polyether Ether Ketone) – a thermoplastic that combines exceptional strength with thermal stability and chemical resistance. Thanks to PEEK 3D printing, you can now deliver robust, complex aerospace parts in a matter of days rather than weeks.

Here’s everything you need to know about PEEK and the growing role of polymers in aerospace…

Why polymers are reshaping aerospace

Metals like aluminium and titanium have dominated aerospace production for years. But polymer composites in the aerospace industry have steadily proven their value, offering a whole host of properties that surpass traditional materials. By adopting polymers into your workflow, you can cut fuel consumption, reduce emissions, and design freely without the limitations of conventional tooling.

Polymers also open the door to faster, more flexible manufacturing. Metals require complex machining and long lead times, whereas advanced polymers give you the freedom to prototype and produce functional parts quickly. This keeps your projects on track and ensures you remain responsive to change.

The PEEK advantage

When it comes to polymers in aerospace applications, few materials perform as impressively as PEEK. Here’s why it’s fast becoming the go-to material for aerospace engineers:

- PEEK’s low density helps cut aircraft mass and fuel burn, increasing your aircraft’s efficiency

- It offers exceptional thermal reliability and continues to perform even over 250°C

- It can withstand harmful aviation fuels, solvents, and excess moisture, reducing the need for costly maintenance

- With low smoke and toxicity levels, PEEK helps to keep your passengers safe

- Its exceptional fatigue and vibration resistance ensures your components stay in service for longer

When you choose PEEK 3D printing material, you can rest assured that the parts you design won’t just pass regulatory requirements, but will also perform reliably for many years of service.

Where you’ll find PEEK already at work

PEEK aerospace applications are expanding massively across the industry. The material has moved far beyond just experimental use, and can now be seen in mainstream aerospace engineering. You’ll now find PEEK used in:

- Engine components, from seals to turbine blades and everything in between

- Airframe brackets and connectors

- Electrical insulation and connectors

- Hydraulic seals and gaskets

- Cabin interiors

- Protective tubing for wiring and fibre optics

Shaping a greener, smarter future for aerospace

With aviation accounting for 2.5% of global CO₂ emissions, the aerospace sector is under more pressure than ever to deliver innovative solutions that don’t harm the planet. Every kilogram of weight saved can translate into thousands of litres of fuel saved over an aircraft’s lifespan.

Polymers like PEEK are playing a vital role in cutting aircraft weight and supporting more efficient manufacturing processes, which directly contributes to reduced CO₂ emissions.

Polymers are also fuelling innovation in design. Complex, aerodynamic brackets, housings and seals that were once impossible to machine can now be 3D printed in high-performance thermoplastics like Antero 840CN03 and Antero 800NA. This freedom enables you to push boundaries in design and deliver smarter solutions much faster.

PEEK vs traditional metals

Still weighing up whether PEEK is the right move for you? Here’s a side-by-side comparison:

| Property | PEEK sheets | Traditional metals |

| Weight | Lighter for increased fuel efficiency | Heavier, uses up more fuel |

| Heat resistance | Performs beyond 250°C | Some metals weaken at high temperatures |

| Corrosion resistance | Resistant to harmful chemicals and fluids | Prone to corrosion |

| Manufacturing | Enables you to create complex geometries | More restricted in terms of design |

| Safety | Low smoke and low toxicity | Greater fire risk |

Harness the power of PEEK

At Tri-Tech 3D, we’re here to help you unlock the true performance edge of PEEK. Our cutting-edge Fortus 3D printers, combined with our industry-leading selection of PEEK materials, are ideal for demanding aerospace environments, allowing you to create lightweight, high-strength parts that keep your aircraft flying efficiently.

Ready to see how PEEK could elevate your next aerospace project? Get in touch to discover how advanced polymers can transform your designs, your workflows, and the future of your aircraft.