Picking the right 3D printing solution for your business is no small feat. While search engines can bombard you with a bewildering range of technologies and systems, at Tri-Tech 3D, we think of choosing the best 3D printer as selecting the right tool for the job.

The team at Tri-Tech 3D have many years of experience of partnering with companies and organisations to identify and the right 3D printing technology for your range of applications.

Get in touch today and speak with one of team to explore how you could benefit from the below range of applications.

To find your way to the 3D technology and system that suits you, here are some preliminary questions to ask yourself.

- What range of applications do you plan on using the printer for?

- What type of material and properties do you require i.e. impact resistance, wear resistance, chemical resistance, heat resistance

- What size range of components do you plan on producing?

- What tolerances are you working to and do you require accuracy and repeatability?

- How many parts per year will you be printing?

- What return on investment do you need to achieve?

- Who will be operating and maintaining the 3D printer?

- Where will the 3D printers be installed?

Jigs & Fixtures

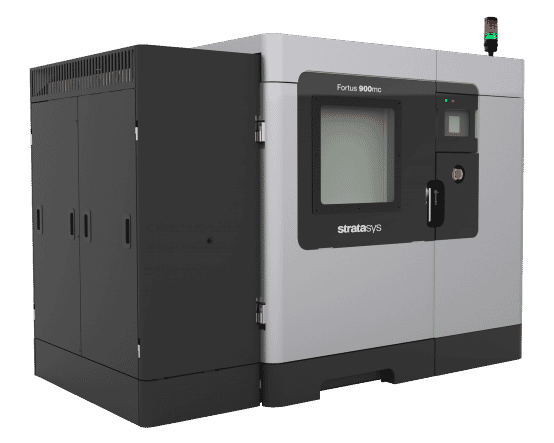

Printers best suited for the application of 3D printing strong jigs & fixtures

Low Volume Manufacturing

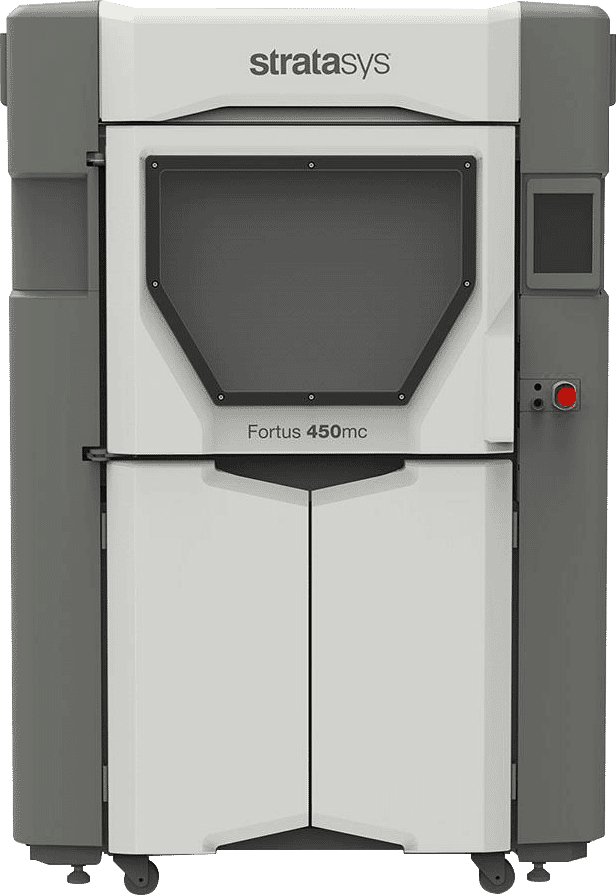

Printers best suited for the application of low volume manufacturing

Production Parts

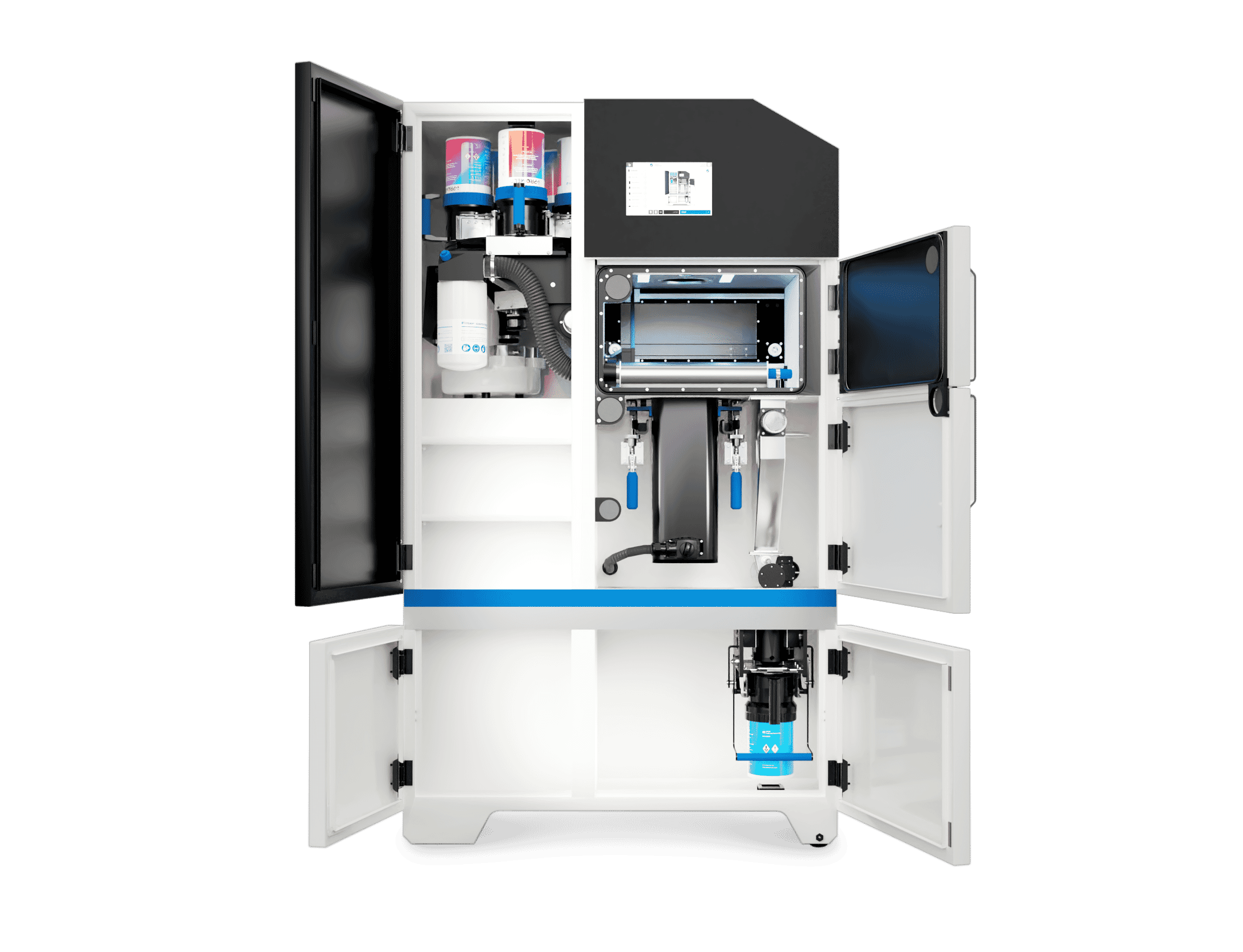

Printers best suited for the application of production parts

Rapid Prototyping

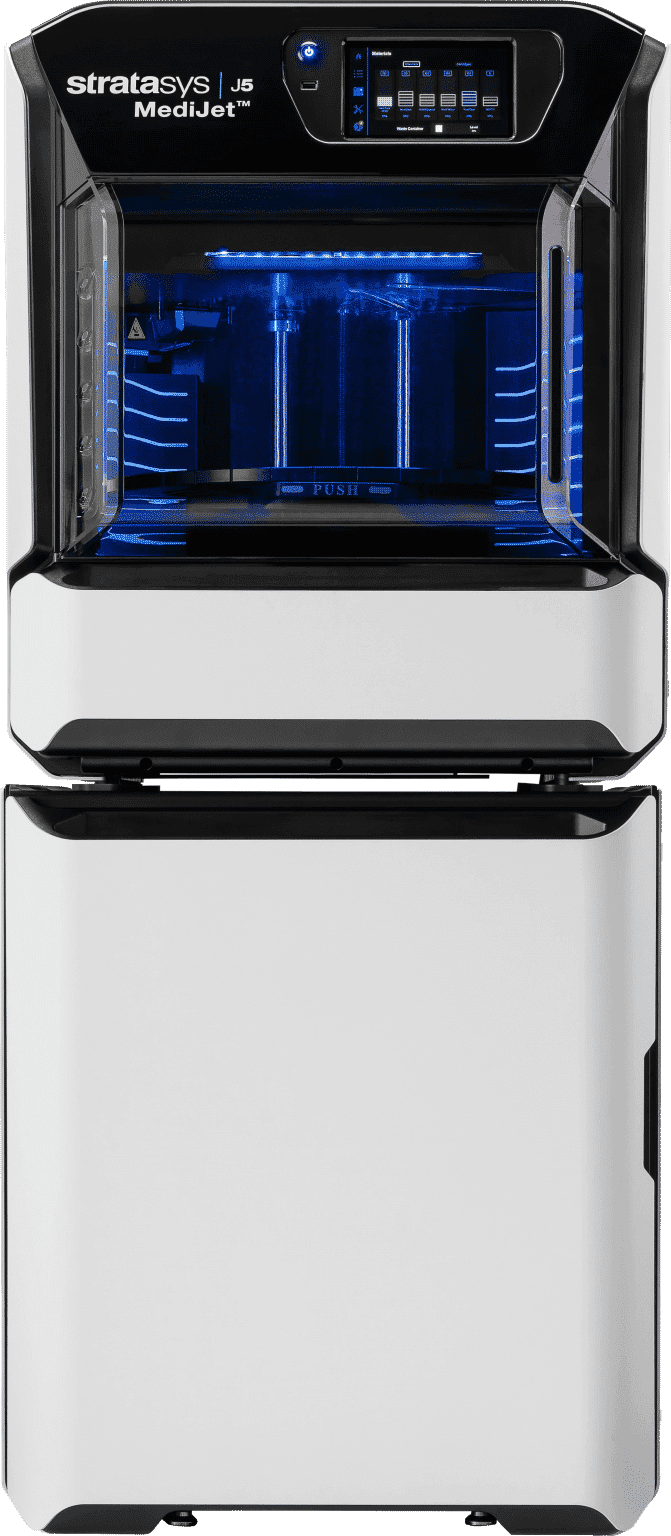

Printers best suited for the application of rapid prototyping