North Manchester utilise the J5 MediJet to assist in complex surgical planning

North Manchester General Hospital’s Maxillofacial Department plays a pivotal role in diagnosing and managing complex craniofacial and oral conditions in both adult and paediatric patients. The department supports a wide spectrum of clinical specialties, including head and neck oncology, craniofacial trauma, jaw surgery and orthodontics, the regional burns and scar therapy and the cleft lip and palate service as well as Manchester Facial prosthetic service.

With a busy clinical workload and an emphasis on high-risk trauma and cancer patients, the department’s in-house laboratory sought a solution that could streamline its model production and improve turnaround times for surgical planning. Traditionally, all maxillofacial models and guides were produced through manual laboratory techniques a time-consuming process that could take several days to complete.

The Shift to Digital Workflow

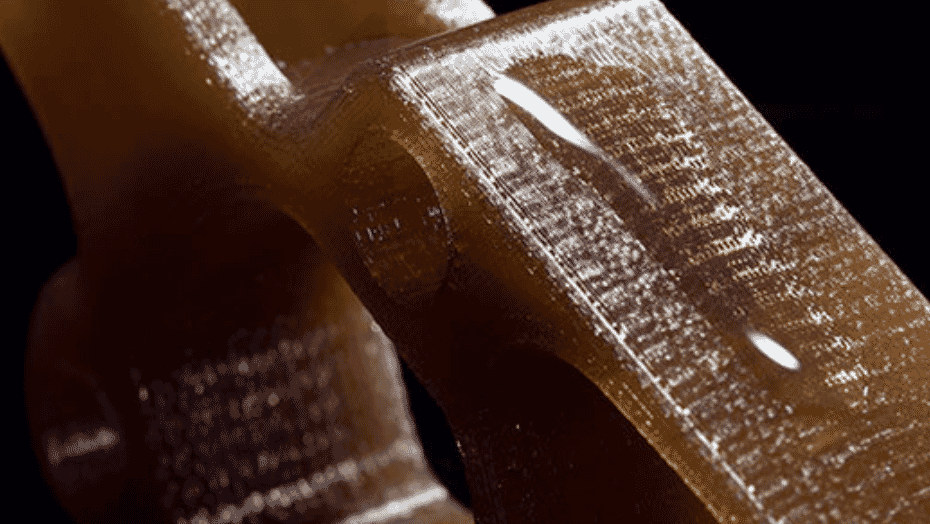

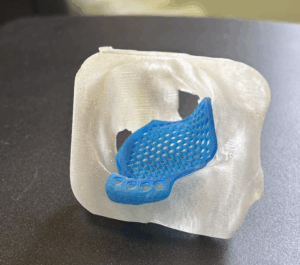

To address these challenges, the laboratory introduced additive manufacturing technology using the Stratasys J5 3D Printer, complementing their existing Objet30 Prime system which was implemented in 2017. The J5’s advanced capabilities, combined with Med610 biocompatible material, has greatly enhanced the department’s approach to surgical preparation; enabling them to achieve tighter deadlines with its superior printing capacity, speed and material choice.

Today, the J5 printer is utilised daily to produce patient-specific surgical guides, osteotomy cutting guides, anatomical teaching models, and paediatric trauma reconstructions. The workflow integrates seamlessly into the department’s digital pathway:

Consultation and Imaging – The clinician assesses the patient and requests high-resolution CT imaging.

Data Processing – The DICOM files are transferred to the laboratory, where specialists use Materialise Mimics to create an accurate 3D STL model.

Virtual Surgical Planning – The file is then imported into Materialise ENLIGHT CMF, enabling surgeon and scientist to simulate osteotomies, resections, and reconstructions virtually.

Design and Preparation – Finalised designs are optimised in Materialise 3-Matic before being imported into GrabCAD Print for fabrication on the Stratasys J5.

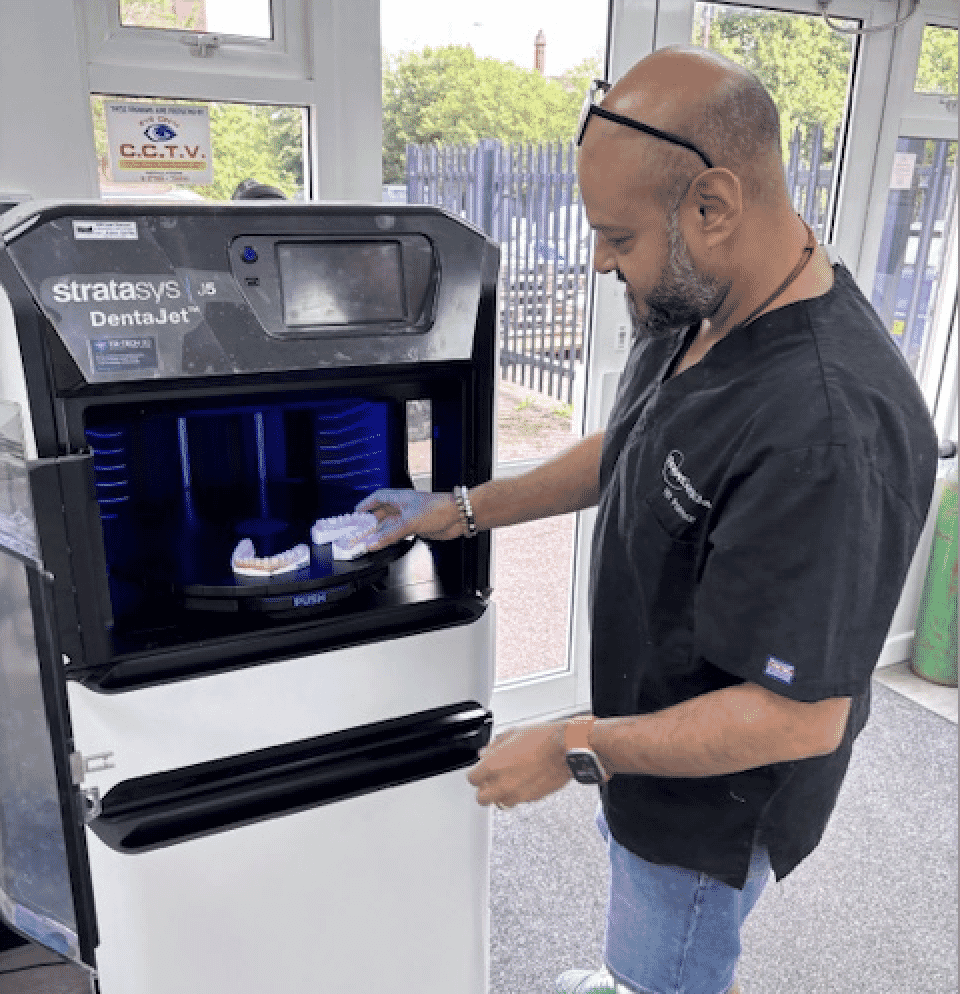

Printing and Post-Processing – The models are printed, cleaned, and prepared for surgical use within hours.

Measurable Impact on Patient Care

With the J5, turnaround times have been reduced dramatically from several days to as little as 24–72 hours, a critical improvement for trauma and oncology cases where time is a decisive factor. This rapid production allows surgeons to visualise complex anatomy, plan resections with millimetre precision, and practice intricate reconstructions before entering the operating theatre.

The J5’s multi-material and full-colour capabilities enable the creation of highly detailed anatomical models that clearly distinguish between bone, soft tissue, and pathological structures. This visual accuracy enhances preoperative communication, surgical confidence, and patient understanding. Additionally, its compact, office-friendly footprint allows the printer to operate efficiently between the Maxillofacial technicians’ workstations, supporting continuous workflow with minimal disruption.

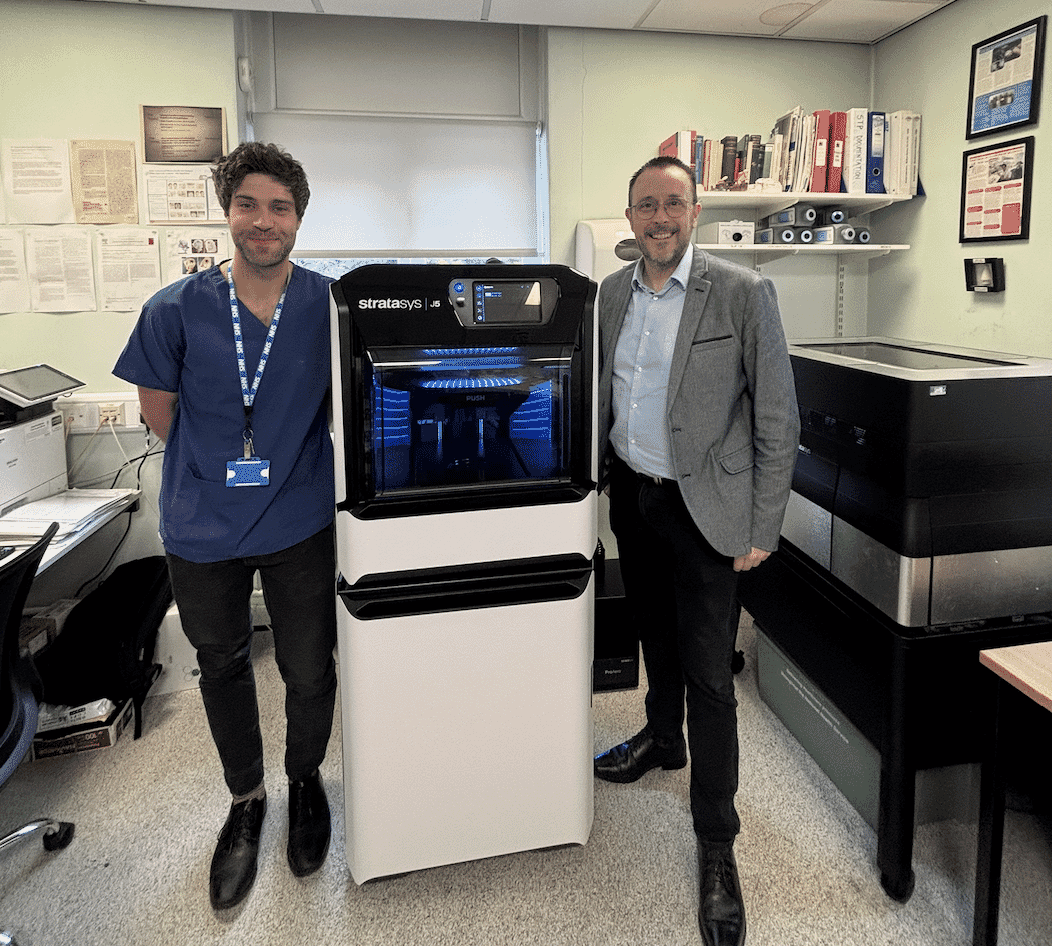

Oliver Burley, Reconstructive Scientist at Manchester NHS Foundation Trust commented:

The J5 has completely transformed the way we work. We can now produce accurate, patient-specific models and surgical guides in a fraction of the time it used to take. For our trauma and cancer patients, that time saving can be critical. The ability to visualise the patient’s anatomy in full colour before surgery has improved planning, precision, and ultimately patient outcomes. The J5’s specification has enabled us to meet turnaround times on cases that were previously not possible.

Looking Ahead

The department’s success with 3D printing has opened new opportunities for interdisciplinary collaboration. Future ambitions include extending digital fabrication to a larger pool of clinicians, expanding the use of 3D models for surgical planning, implant design, and patient education across multiple clinical domains.

Conclusion

The adoption of the Stratasys J5 3D Printer has transformed the Maxillofacial Department’s approach to surgical planning in Manchester. Through faster production, improved model accuracy, and enhanced surgical visualisation, the department now delivers life-changing care with greater precision and efficiency.

By integrating 3D printing into their clinical pathway, the team continues to set a new standard for patient-specific, data-driven surgical innovation in the NHS.