Why 3D Print in metal?

One of the biggest misconceptions amongst the uninitiated is that AM is all about quirky photopolymers and thermoplastics – and that it’s impossible to produce ‘serious’ metal-based componentry. In fact, Tri-Tech 3D’s metal 3D printer range is one of our biggest sellers – and the results have proved themselves in ultra-demanding sectors from aerospace to defence.

Tri-Tech 3D’s team is always on hand to help our clients find the right 3D printer that prints metal. But in this blog, we’ll introduce the essential metal 3D printer concepts, examine some of the associated hardware and materials, and lead you through the key benefits that make this such an effective branch of AM.

How does a metal 3D printer work?

Every metal 3D printer works on a slightly different principle, depending on whether it specialises in Selective Laser Melting (SLM), Electron Beam Melting (EBM) or Direct Metal Laser Sintering (DMLS). But in this general introduction, let’s start with the fundamental concept of powder bed fusion that underpins most types of metal 3D printing.

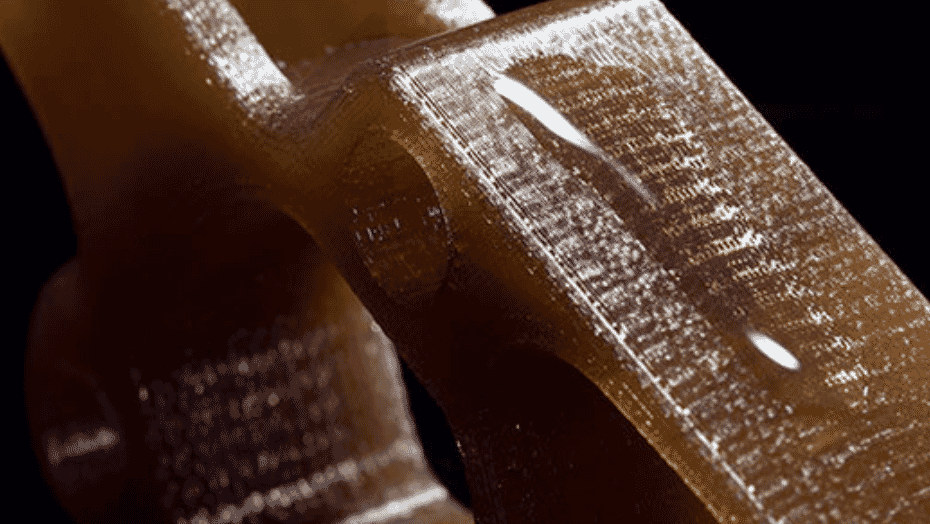

The powder bed fusion process typically begins with small canisters of specialist metal powder being loaded into the 3D printer’s cartridge bays. Next, a thin layer of this powder is spread across the print bed, while the build chamber fills with an inert gas like argon to prevent it from oxidising (the high temperatures involved in metal 3D printing also mean support structures are required). Finally, a powerful laser or electron beam melts (or ‘sinters’) specific areas to fuse together the particles and start generating the 3D object layer-by-layer, based on the dimensions specified by the designer.

But metal 3D printing is moving onwards all the time. For one of the most exciting advancements in the sector over the last decade, ask our team about ADDiTEC technology, which employs Directed Energy Deposition (DED) and Liquid Metal Jetting (LMJ) for high-performance, sustainable metal 3D printing in sectors from aerospace to automotive.

What are the benefits of 3D metal printing?

The widespread adoption of 3D metal printing across the gamut of global industry speaks to the eclectic benefits of this technology. Some at-a-glance advantages include:

– Open-ended design with scope for detailed, intricate and complex geometries

– Reduced waste relative to traditional subtractive manufacturing

– Easy tailoring and customisation for creation of bespoke products

– Durable, high-strength parts with resistance to damage and heat

– Efficient, lightweight parts with optimised structures and part consolidation

– Suitable for either rapid prototyping or functional end-use components

What 3D printers can print metal?

From industrial behemoths to compact desktop units, the snowballing popularity of metal 3D printing means there’s plenty of choice on the market. When it comes to balancing affordability with quality, however, the One Click Metal MPRINT+ demands to be on your shortlist. Combining a state-of-the-art 200W fiber laser and galvo scanner with a generous build volume (150mm x 150mm x 150mm) and inert nitrogen gas outlet, this unit’s trump card is its compatibility with a range of metals including aluminium and stainless steel.

At Tri-Tech 3D, we’ll also be glad to give you a demo of our powerful ADDiTEC metal 3D printers. Take a closer look at the ADDiTEC AMDROiD X, whose self-contained Laser Directed Energy Deposition (LDED) system allows rapid and precise in-field production and repair of large-scale metal parts. Or investigate the ADDiTEC Hybrid 3, whose advanced Liquid Metal Jetting (LMJ), Laser Directed Energy Deposition (LDED) and CNC machining allows a unique fusion of additive and subtractive manufacturing. For more on these models – or any other 3D printer in the range – simply get in touch with our team.