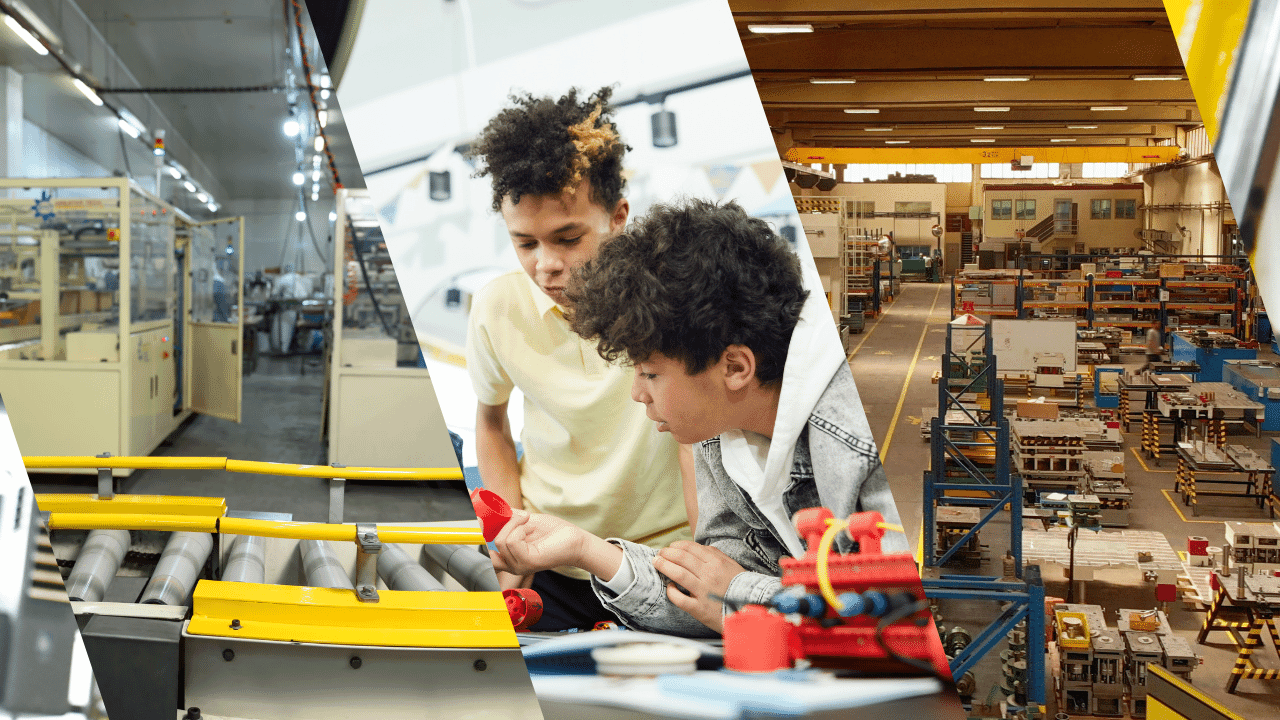

Discover how UltiMaker’s professional 3D printers - backed by Tri-Tech 3D - are transforming industries with practical, real-world solutions across packaging, education, and manufacturing.

At Tri-Tech 3D, we believe innovation starts with solving real-world problems – faster, smarter, and more cost-effectively, and UltiMaker is one of the brands in our portfolio that continues to lead the way across a range of sectors in additive manufacturing. From streamlining packaging lines to revolutionising classroom learning and transforming everyday manufacturing, the applications of UltiMaker’s professional 3D printers go far beyond prototyping. Here’s how:

📦 3D Printing in the Packaging Industry: Speed and Agility on the Line

Automated packaging lines are under constant pressure to deliver, fast. When a machine part breaks or a new product format is introduced, delays can cost thousands. That’s where UltiMaker steps in.

Key packaging benefits of UltiMaker 3D printing:

- Reduced downtime: Print replacement parts and custom tools in-house to keep lines running.

- Custom grippers & guides: Adapt robots and conveyors quickly to fit new packaging formats.

- Material versatility: Use engineering-grade materials (like PETG, Nylon, or carbon-fibre-filled composites) tailored to your production needs.

Real-World Example: Custom End-of-Arm Tooling for Packaging Lines

When it comes to automated packaging, downtime is costly – which is why many production teams are turning to UltiMaker to create custom end-of-arm tooling for robotic systems. A great example comes from a beverage packaging line that replaced traditional metal can-pushers with a custom 3D printed solution. The new design featured a rigid inner core made from UltiMaker PC and an outer layer printed in Igus i150, a low-friction material ideal for repetitive motion. This dual-material design created a larger surface area for contact, improving product handling while reducing wear and tear. And here’s the clever part, the internal core is printed in a contrasting colour, serving as a wear indicator: as the outer layer wears down, the inner colour begins to show, letting operators know it’s time for a replacement.

Companies using UltiMaker for packaging report reduced lead times, lower costs, and faster adaptation to market demands – all without sacrificing quality or reliability.

🎓 3D Printing in Education: Empowering the Next Generation of Innovators

From primary schools to universities, educators are embracing 3D printing as a hands-on, engaging tool to bring STEM learning to life.

Why UltiMaker stands out in education:

- Easy to use: Reliable printers, intuitive software, and minimal maintenance mean teachers can focus on teaching – not troubleshooting.

- Curriculum-ready resources: UltiMaker offers ready-made lesson plans, project ideas, and training to get started fast.

- Real-world learning: Students design and print functional parts, prototypes, and models that build problem-solving, creativity, and critical thinking skills.

Real-World Example: Classroom Bridge Building with 3D Design

UltiMaker offers a huge range of lesson plans and ‘out of the box’ examples for teaching. One standout classroom project involves students designing and constructing scale model bridges using a combination of traditional materials and 3D printed parts. In this hands-on activity, students research different types of bridge structures, brainstorm their own design, and then build a working model using their own designed 3D printed connectors and traditional materials like balsa wood and glue. The 3D printed joints allow for greater flexibility in testing engineering principles like load distribution, tension, and compression – giving students a tangible, interactive way to apply physics and design thinking in real time.

Whether it’s creating topographic maps in geography or engineering parts for robotics teams, UltiMaker bridges the gap between theory and practice in the classroom.

🏭 3D Printing in Manufacturing: Smarter Production at Every Stage

In general manufacturing, efficiency is everything – and UltiMaker’s industrial desktop 3D printers are giving engineers and technicians the tools to work smarter, not harder.

Top manufacturing applications include:

- Jigs, fixtures, and assembly aids: Produce durable tools in-house at a fraction of the cost and lead time.

- Design validation: Test and iterate prototypes faster, enabling quicker product development cycles.

- Spare parts on demand: Minimise inventory costs by printing parts when and where they’re needed.

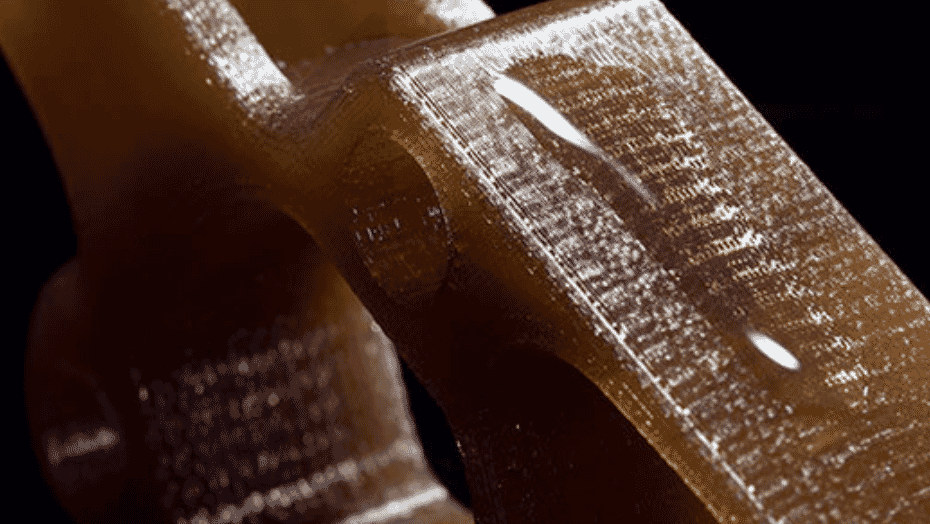

Real-World Example: Custom Jigs and Fixtures for Assembly Lines

In general manufacturing, 3D printing is becoming a go-to solution for producing custom jigs, fixtures, and production aids. These components – once expensive and time-consuming to machine – can now be designed, tested, and deployed within days using UltiMaker printers. From ergonomic assembly tools to precision alignment guides and fixture plates, manufacturers are streamlining operations, cutting costs, and improving consistency across production lines.

Among the many applications, one example includes a connector component designed specifically as a mold insert for injecting parts used in water and air pipe assemblies. Printed in carbon fiber-reinforced nylon, the part offers the strength and heat resistance needed for demanding molding environments while allowing for rapid prototyping and on-demand production. This flexibility helps manufacturers adapt quickly to design changes and short-run production needs – all without the traditional lead times or costs of metal tooling.

With UltiMaker, manufacturers gain the agility to respond quickly to changing requirements and optimise processes across the board.

Beyond the Build: Shaping the Future with 3D Printing

From education to packaging to general manufacturing and more, it’s clear that additive manufacturing is no longer an experimental tool – it’s a core part of modern workflows. As applications continue to evolve, so too must the way we think about prototyping, tooling, and production.

At Tri-Tech 3D, we’re fortunate to work alongside forward-thinking organisations who are not just adopting additive manufacturing – they’re redefining what’s possible with it. As an official UltiMaker partner, we stay close to the technology and the people using it, our team will work with you to recommend the right system, provide tailored training, and support your journey from idea to implementation.

The question isn’t if 3D printing has a place in your workflow – it’s how you can harness it most effectively and as always, we’re here to help. Get in touch with the Tri-Tech 3D team.

📞 Call us on 01782 814551

📧 Email us at info@tritech3d.co.uk

💬 Book a demo with one of our 3D printing specialists: Book your UltiMaker demo here

We’re here to help you explore how Additive Manufact can fit into your workflow – just get in touch!