From Design to Diagnosis: How 3D printing is reshaping the healthcare industry

A MedTech insight with Silvana Arteaga Moreno, Medical Sales Specialist at Tri-Tech 3D.

3D printing is playing an increasingly important role in the delivery of healthcare. Whether it’s being used to produce dental appliances at scale, support surgical planning with anatomical models, or prototype custom medical devices, additive manufacturing is enabling faster, more personalised, and more efficient solutions for clinicians and patients alike.

Silvana is the Medical Sales Specialist at Tri-Tech 3D, a leading UK provider of industrial 3D printing solutions. With a background in biomedical engineering, product design and rehabilitation technology, she supports healthcare organisations in adopting 3D printing technologies in both clinical and commercial settings.

We sat down to get to know Silvana, and spoke about the current landscape, where she’s seeing the biggest impact, and what’s next for additive manufacturing in the medical space.

Getting to know Silvana…

Forging a professional path in healthcare and additive manufacturing.

“I clearly remember reading an article in 2011 about the first 3D printed kidney, developed by a researcher named Anthony Atala. Although it was just a conceptual prototype at the time – it represented the beginning of endless possibilities for addressing complex healthcare challenges through additive manufacturing.”

I’ve always had a strong interest in healthcare technology,” Silvana explains.

“I’m fascinated by 3D printing and advanced technologies, and equally passionate about helping people. That combination naturally led me to the medical and dental side of additive manufacturing, which reduces the cost and widens access to life saving, and life improving materials or products”.

My undergraduate studies in Bolivia focused on Biomedical Engineering, and I later moved to London to study Rehabilitation Engineering at UCL which further enhanced my understanding of how technology can be applied practically to improve quality of life for patients.”

After deepening her knowledge in research and development for prosthetics and orthotics, Silvana went on to complete a Master’s in Integrated Product Design at Brunel University.

“This experience taught me new ways that design and engineering, within the 3D printing industry, can come together to create solutions that are not only functional but also efficient and scalable.”

Making an Impact at Tri-Tech 3D

Now a year into her role at Tri-Tech 3D, Silvana has developed an even stronger understanding of how additive manufacturing is being adopted across the healthcare sector.

“Tri-Tech 3D supports a broad spectrum of organisations – from NHS hospitals and dental laboratories to medical device manufacturers,” she explains. “It’s been incredibly rewarding to see how 3D printing is helping these teams optimise workflows, cut lead times, and ultimately improve patient outcomes.”

She highlights the adaptability of 3D printing as one of its greatest strengths – an ever-evolving capability that she sees reflected in the growing number of real-world applications.

“The biggest highlight for me has been the volume of knowledge I’ve gained – not only from my colleagues, but also through working closely and engaging with customers and the wider med-tech community. I’ve seen how companies like Stratasys are playing a key role in shaping the future of healthcare manufacturing.”

Silvana notes that every healthcare provider faces unique challenges – whether it’s the need for patient-specific anatomical models, enhanced surgical planning tools, or faster device prototyping. “3D printing provides the flexibility to meet these needs in a cost-effective way. What’s encouraging is the clear shift in mindset among healthcare professionals. There are endless opportunities for innovation and I’m delighted to see new evidence of creative and useful applications very regularly in my daily interactions with the industry”.

Materials & applications that are bringing real-world change.

Practical examples: from hospitals to dental labs.

In clinical settings, Additive Manufacturing is proving its value across several disciplines.

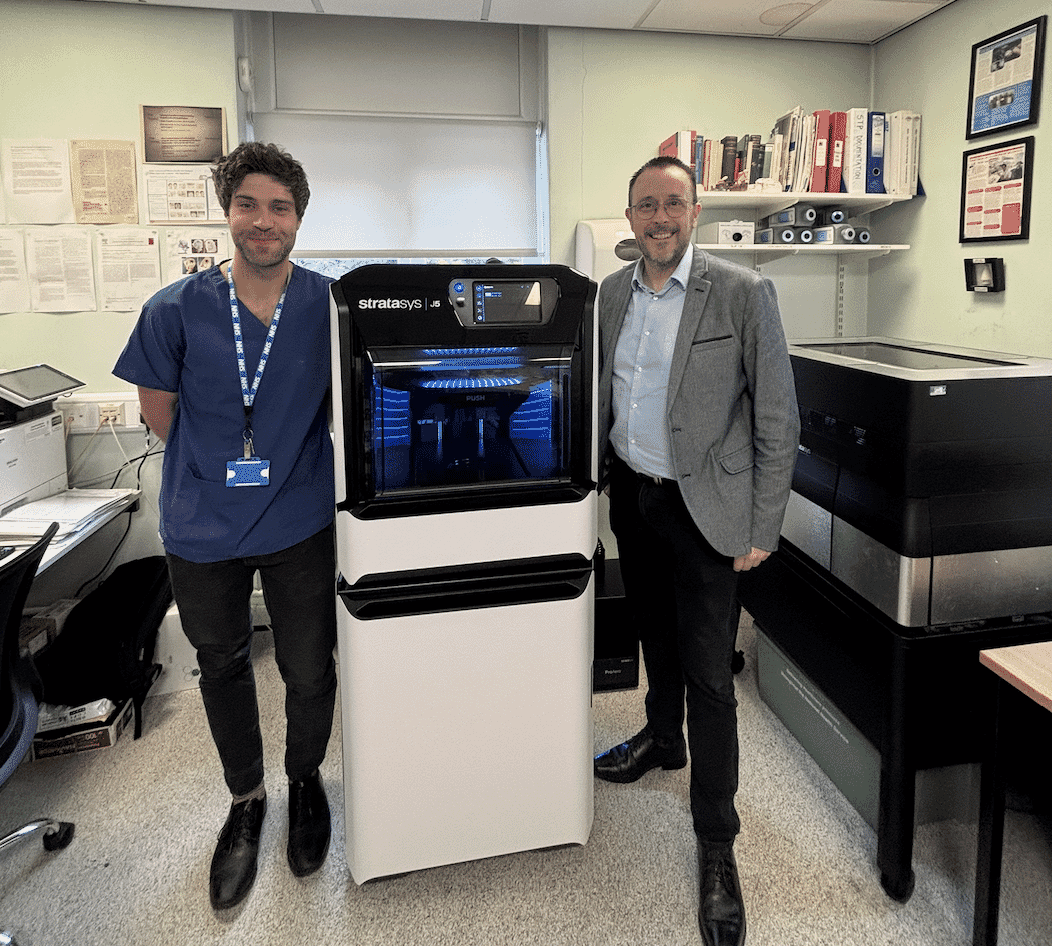

“In hospitals, we’re supporting teams to create anatomical models from patient scan data to aid with surgical planning and communication,” Silvana explains. “Point-of-care 3D printing is becoming more common, with dedicated labs now operating within some NHS trusts.”

Following the recent grand opening at NHS Southmead Hospital in Bristol, the Tri-Tech 3D team – together with representatives from Stratasys and Amy Davey, Senior Reconstructive Scientist at the North Bristol NHS Trust – was proud to launch the new 3D printing facility this April. Among the projects showcased was the hospital’s use of 3D printing to produce custom-fit helmets for babies with flat head syndrome, supporting better clinical outcomes and improving patient comfort.

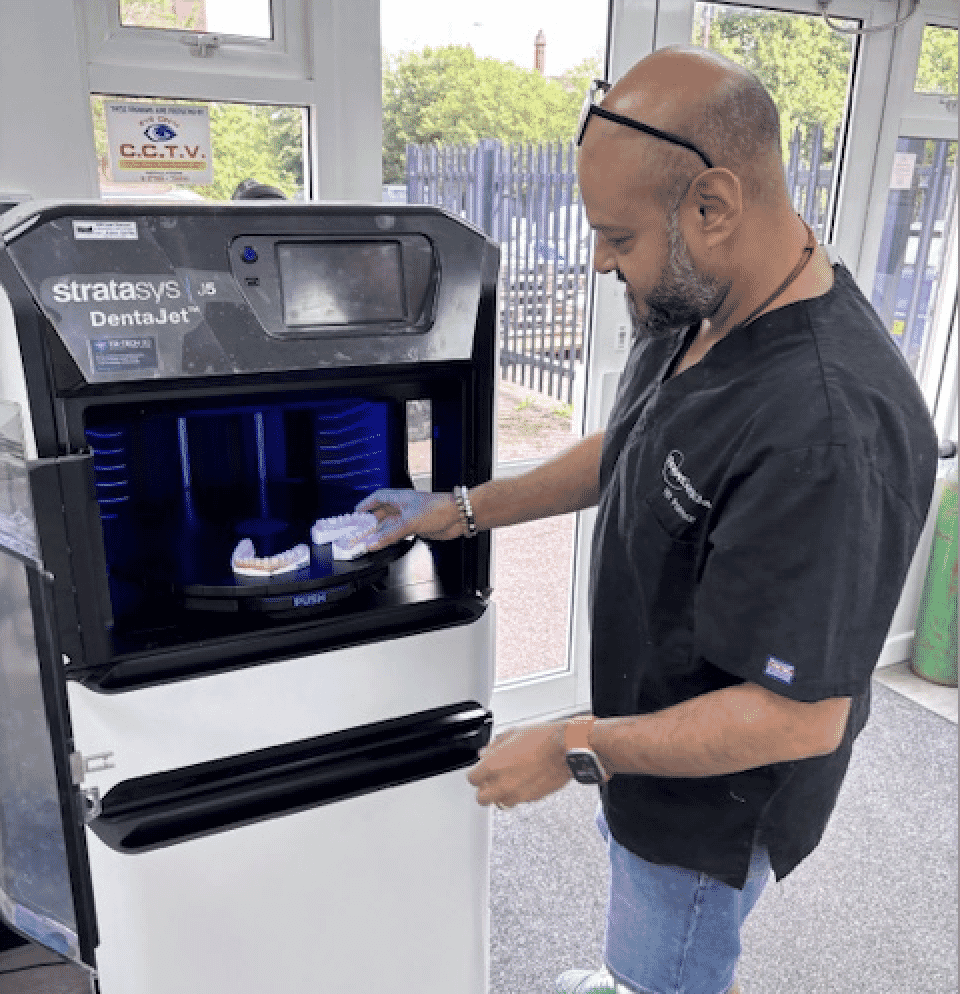

In dentistry, the uptake is even more advanced. “Dental labs are using printers like the Stratasys J5 DentaJet to produce a high volume of precise, biocompatible appliances – everything from surgical guides to full-colour dentures using the new TrueDent resin. It’s helping labs deliver faster turnarounds and reduce reliance on labour-intensive manual processes.”

Material innovations that are driving interest

Silvana explains that much of the recent growth in healthcare 3D printing has been driven by developments in biocompatible materials.

“We’re seeing more and more healthcare providers asking about resins that meet medical-grade standards,” she says. “In particular, dental labs and hospital teams want materials that are certified for patient contact – whether that’s for surgical guides, splints, or temporary restorations.”

One area where this demand is especially clear is in dentistry, where high-throughput systems like the Stratasys J5 DentaJet are being used alongside new material formulations such as TrueDent™, a full-colour, biocompatible resin for permanent dental appliances.

“For training and pre-surgical planning, the Digital Anatomy Materials from Stratasys are making a noticeable impact too,” she adds. “Clinicians we work with value the lifelike feel and behaviour of these models – it gives them more confidence when preparing for complex procedures, and helps improve communication within surgical teams.”

Trends and Future Developments in Healthcare Additive Manufacturing

Additive manufacturing in healthcare is moving beyond prototyping and into real-world clinical impact. According to Silvana, one of the most significant shifts is the rise of patient-specific solutions at scale. “There’s a clear trend towards personalisation at scale – particularly in areas like clear aligners and dental prosthetics,” she explains. “From dental aligners to orthopaedic implants, 3D printing enables precise customisation while still maintaining production efficiency.”

Another major area of growth is Point-of-Care 3D printing, where hospitals establish in-house printing capabilities to produce anatomical models, surgical guides, and customised tools on demand. “We’re seeing more interest in on-site 3D printing within hospitals,” she says. “This not only reduces turnaround times but also improves surgical planning and communication with patients.”

Additive manufacturing is also playing a transformative role in medical education and training. Silvana notes the increasing demand for lifelike, pathology-specific models. “Medical education is becoming much more efficient and optimised by the integration of 3D-printed models, which can replicate rare or complex conditions, helping surgeons rehearse difficult procedures in ways that cadavers or generic models can’t.”

She shares a recent example from an eyelid surgery convention in Austria, where two training stations: one using real cadavers and one using 3D-printed models – each offering unique advantages. While cadavers provided anatomical realism, the 3D printed models allowed surgeons to train on specific pathological cases, offering a level of customisation traditional methods can’t match.

Looking further ahead, Silvana sees the biggest opportunities in several key areas:

- Patient-specific implants, particularly in orthopaedics and maxillofacial surgery

- Biocompatible materials with enhanced mechanical properties and clearer regulatory pathways

- Advanced training models for rare or complex surgical procedures

- AI integration, enabling smarter design automation and surgical planning

“Whether it’s prosthetics, surgical tools or diagnostic components, the ability to iterate quickly with 3D printing means innovations can be tested and refined much faster than with traditional manufacturing,”

As for those just starting out integrating 3D printing into healthcare uses, Silvana offers practical advice:

Even though 3D printing has been evolving and improving since it began 30 years ago, purchasing a first printer can still feel unfamiliar and intimidating.

“Our team has several decades of experience learning different uses and applications for 3D printers, and our Stratasys products are pioneering in the medical industry. I can help you to identify exactly how to incorporate a 3D printer to optimize your workflow, massively reduce long term costs and customize products. This not only improves business processes, but also increases the quality of the products that can play an essential part in customers or patients’ lives.

Whether you’re just starting your 3D printing journey or looking to scale up existing capabilities, Silvana and the Tri-Tech 3D team are here to help.

Any questions? Come and chat with us at TCT 3Sixty on 4th–5th June 2025, Stand E10 – right next door to the Med-Tech Expo at the NEC Birmingham.

Can’t make the show? Head over to www.tritech3d.co.uk to explore our full range of healthcare 3D printing solutions.