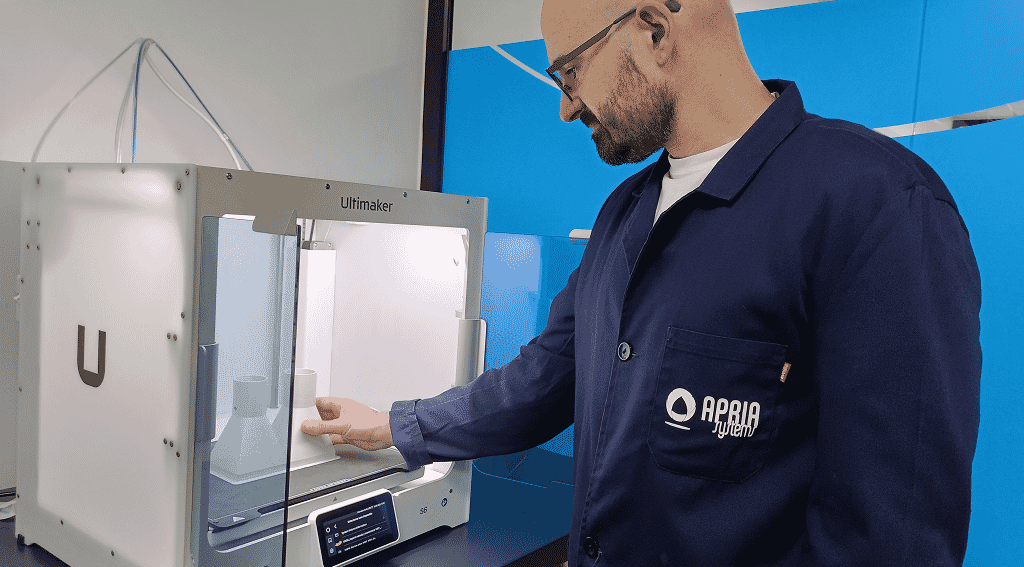

How integrating the UltiMaker S6 into Apria Systems workflow delivered a game‑changing solution

Accelerating Environmental Solutions: Apria Systems Leverages UltiMaker S6

Apria Systems, founded in 2006 as a spin‑off from the University of Cantabria, is a specialist in environmental and chemical engineering solutions worldwide. From purification and waste valorization to sustainable energy projects, Apria delivers tailored technical consultancy alongside engineered products.

The Challenge

Apria’s engineering team, led by Project Engineer Andrés Del Castillo Martín, regularly designs bespoke end-use parts for UV lamp systems and other water/gas treatment hardware. Traditionally, custom parts were machined via CNC, incurring high costs, long delivery times, and limited geometric options – especially problematic for low‑volume or highly precise functional components.

The Solution

Integrating the UltiMaker S6 into their workflow delivered a game‑changing solution:

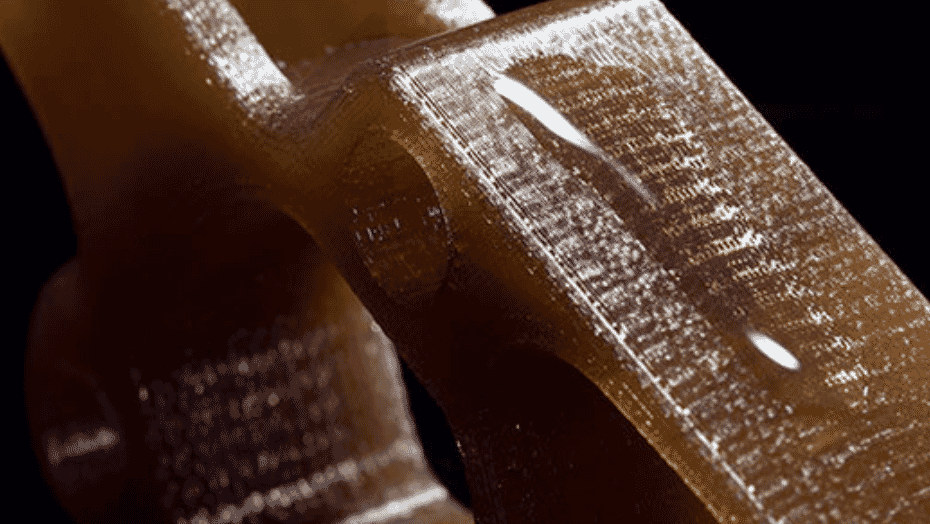

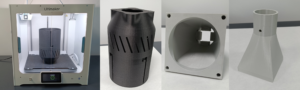

- Rapid prototyping and production of engineered parts in Nylon CF and PLA materials. Example: a custom cooling cone for an annular UV lamp was printed in 21.5 hours (in multiple parts) rather than machined.

- Entirely in‑house manufacturing replaced outsourced, CNC processes, dramatically reducing turnaround time – parts that once took weeks could now be printed in days.

- Integrated UltiMaker ecosystem including Cura slicing software and Digital Factory for monitoring, file control, and remote print management—supported by both UltiMaker and third‑party material profiles.

Results

Since deploying the UltiMaker S6:

- Lead times slashed from weeks to days, enabling faster response to client needs.

- High-quality, chemically resistant components printed on-demand with consistent precision.

- Greater flexibility in design iteration and delivery, with fewer delays, lower cost-per-part, and improved production autonomy.

“With the UltiMaker S6 … it’s possible to create new applications we couldn’t do before.”

– Andrés Del Castillo Martín, Project Engineer, Apria Systems

Why It Works

- UltiMaker Cheetah motion planner

Speeds up print times while maintaining surface quality. - Active bed leveling & dual-drive feeder

Ensures consistent first-layer adhesion and reliable material handling. - Open material system + engineering-grade filaments

Enables chemical-resistant, functional component production. - Digital Factory & Cura

Provides secure, remote print control and job monitoring.

Looking Ahead

Apria continues to adopt the UltiMaker ecosystem as a core part of their additive manufacturing toolkit – enabling faster turnaround, reduced outsourcing, and improved design agility.

Want similar results for your production, prototyping, or custom part manufacturing needs? Get in touch with us at Tri‑Tech 3D, your trusted partner for UltiMaker solutions, and discover how the S6 can deliver on-demand precision, speed, and efficiency.

📞 Call us on 01782 814551

📧 Email us at info@tritech3d.co.uk

💬 Book a demo with one of our 3D printing specialists: Book your UltiMaker demo here

We’re here to help you explore whether the S6 is the right fit for your workflow – just get in touch!