At Tri-Tech 3D, we understand that keeping your additive manufacturing equipment running smoothly is crucial to your productivity. That’s why we offer 3D printer servicing for the full range of Stratasys, UltiMaker, and One Click Metal systems.

Whether you’re managing a single desktop machine or an entire print farm, our manufacturer-trained engineers are here to ensure your printers continue to perform at their best.

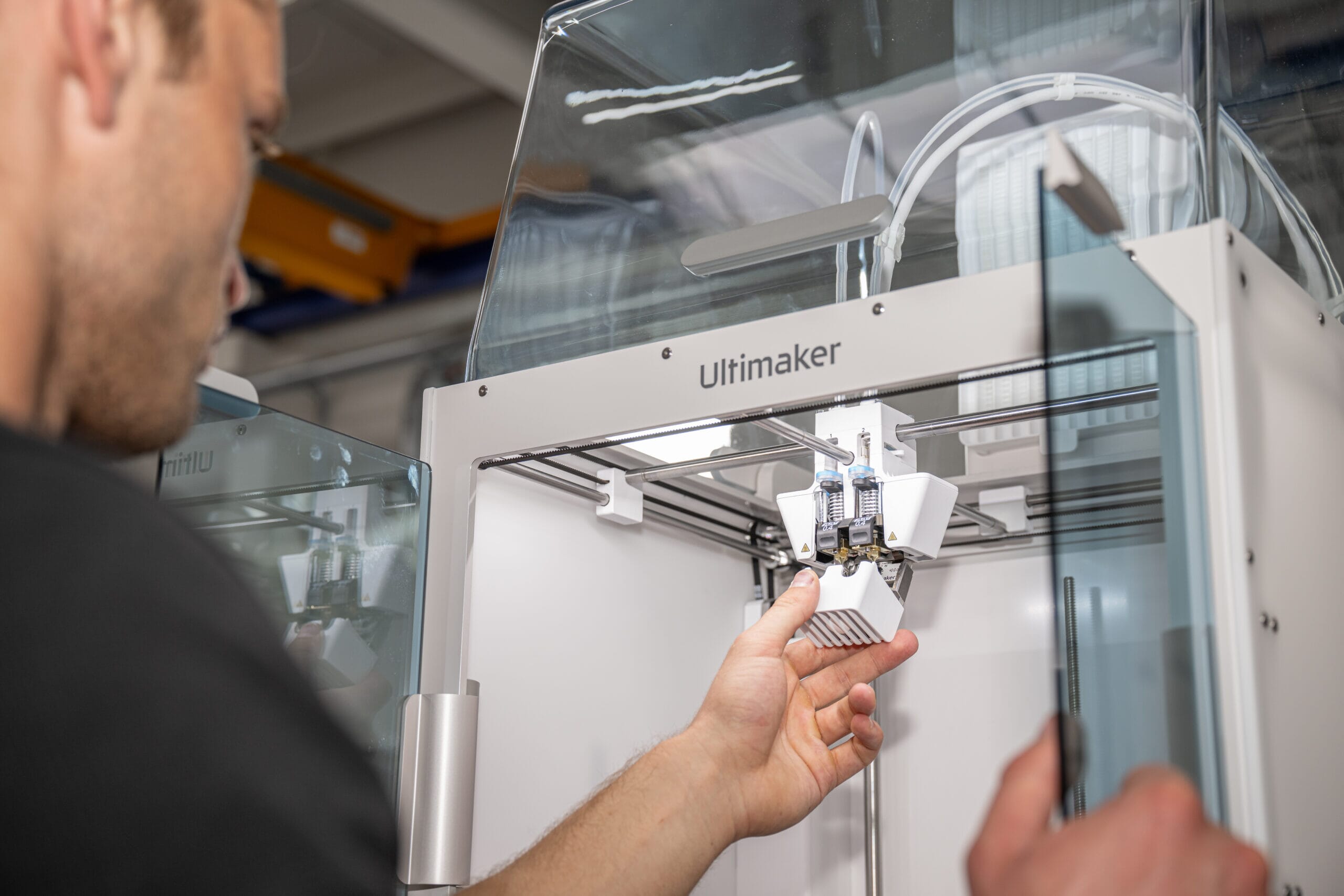

Expert 3D printer repair service

Our 3D printer repair service covers everything from simple fixes to complex faults. Our engineers have a wealth of experience across FDM, PolyJet, SL, P3, and SAF technologies, allowing them to quickly diagnose and resolve almost any issue. It’s very rare we’ll see a problem we haven’t experienced before!

If you have a service contract with us, simply call our support team to arrange a visit. If you’re a time and materials (T&M) customer, we’ll triage your issue remotely, identify any parts that might be required, and provide an initial estimate. If needed, we’ll send an engineer to inspect and repair your machine onsite.

Common 3D printer issues we resolve

- Clogged or blocked nozzles

- Poor filament extrusion

- Bed levelling failures

- Material loading errors

- Print quality inconsistencies

- Software or firmware faults

3D printer care and maintenance guidance

Carrying out regular day-to-day printer maintenance will help you avoid unnecessary downtime and the cost of callouts. Our engineers are always just a phone call away when you need us, but following a few simple steps will keep your equipment operating at its best for longer.

Here are some quick tips for looking after your system:

For PolyJet printers

- Regularly clean the print heads and wiper blade to prevent material build-up

- Check and replace waste containers as and when needed

- Keep your print environment free from dust and debris to avoid contamination

- Follow shutdown and start-up procedures correctly to maintain print quality

For FDM printers

- Regularly inspect and clean nozzles to prevent clogs

- Keep the build plates clean and level for optimal adhesion

- Lubricate all moving parts to ensure smooth motion

- Replace worn tips and extruder components before they impact print quality

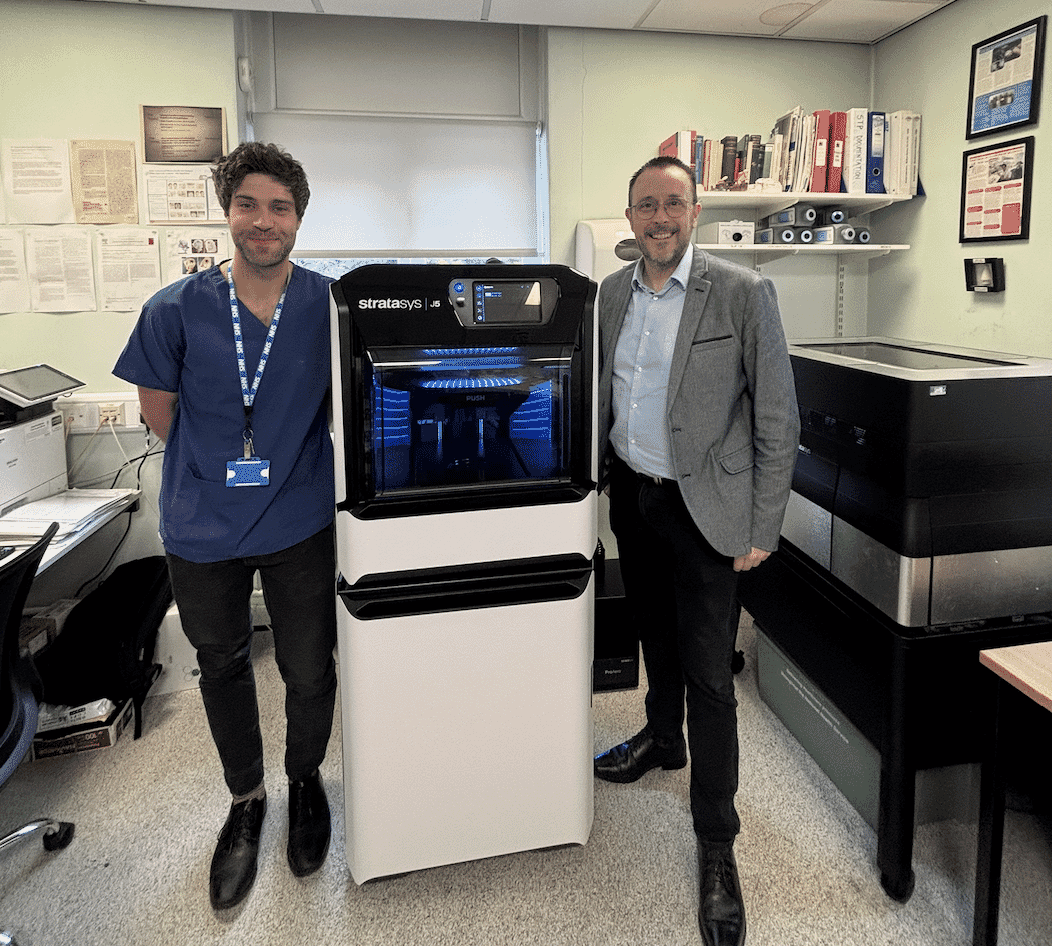

3D printer set-up, training & ongoing support

We don’t just install your printer and walk away. From day one, we provide full set-up, calibration, and user training to help you and your team get the most from your equipment. As your team and applications grow, we’re here to support you with refresher training and retraining for new starters.

And if you want to explore new materials or push your printers into more demanding applications over time, we’re there at every step to help you unlock those opportunities and develop lasting expertise and confidence in additive manufacturing.

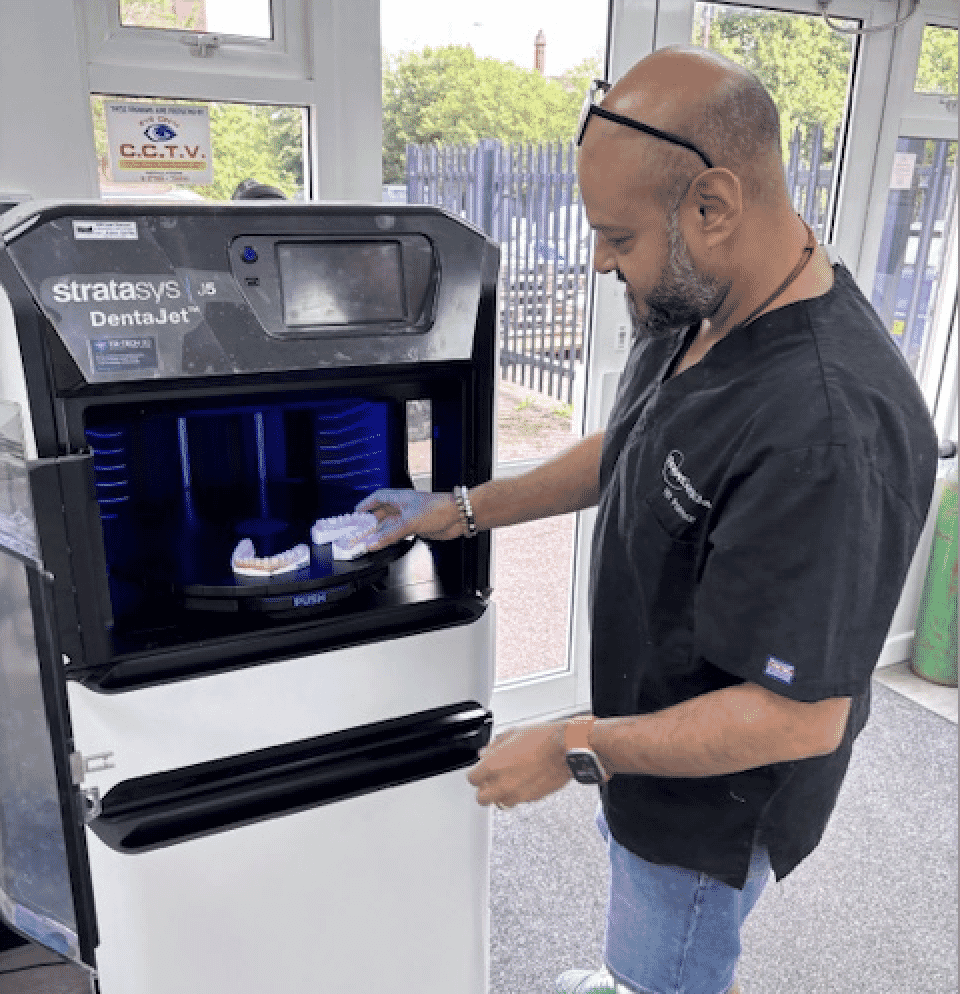

Service packages to suit every need

We offer a comprehensive range of flexible 3D printer servicing contracts that are specifically tailored to your business requirements and budget. Our packages include:

- Full care – unlimited onsite visits, preventative maintenance, priority scheduling within 3 business days, and all parts included (except SHR print heads)

- Flexi-plan – includes 2 onsite visits per year, preventative maintenance, priority scheduling within 4 business days, and parts cover (except SHR print heads)

- Basic care – essential phone support with chargeable onsite labour and travel, parts and updates included

Whichever package you choose, our commitment remains the same: to keep your 3D printers performing at their best, so you can focus on innovation, not interruptions.

Ready to book your 3D printer service?

Get in touch to discuss your 3D printer servicing, maintenance, or repair requirements.